Lightweight High Modulus Carbon Fiber Tow Yarn ...

Carbon fiber tow yarn is a fiber material composed of carbon elements, usually formed by high-temperature carbonization of organic materials (such as polyacrylonitrile) through specific chemical and physical methods. The production process of this material involves multiple steps, including pretreatment, oxidation, and carbonization, to achieve high strength and lightweight characteristics in its structure. During this process, non carbon elements (such as hydrogen, oxygen, etc.) in the raw materials are removed, ultimately forming high-purity carbon fibers.

The diameter of carbon fiber tow yarn is generally small, ranging from a few micrometers to several tens of micrometers. Its production process requires strict temperature and atmospheres control to ensure that the quality and performance of the final product meet standards.

In summary, carbon fiber tow yarn is a type of fiber that has undergone special processing and manufacturing, mainly composed of carbon elements, and has specific production process characteristics.

Real 100% High Strength Carbon Fiber Roving Yarn

Carbon fiber filament yarn is a continuous and extremely fine fiber. Its core component is carbon, which typically accounts for over 90% of its total mass. Carbon fiber filament yarn is the most basic and microscopic unit that constitutes all carbon fiber products (yarn, fabric, prepreg, composite materials). It can be imagined as an extremely small 'carbon filament'.

Carbon fiber filament yarn refers to carbon fiber products that have undergone specific processing, have stable performance, and longer lengths.

6k 12k 24k High Quality Carbon Fiber Filament Yarn

Carbon fiber filament yarn is a continuous carbon fiber material with high strength, high modulus, and lightweight properties. It is usually made from polyacrylonitrile fibers through processes such as pre oxidation, carbonization, and graphitization. Its diameter is only 5 microns (equivalent to ten to one twelfth of a human hair), but its strength can reach more than four times that of aluminum alloy. Long filament carbon fiber has excellent strength and rigidity, and can withstand large tensile forces, making it suitable for high-performance applications such as aerospace, military, and high-end sports equipment.

Hot Sale Carbon Fiber Tow Yarn For Industrial

Carbon fiber filament yarn is a slender fiber composed of carbon element, usually made by high-temperature carbonization process of organic raw materials such as polyacrylonitrile, asphalt, etc. During its production process, the raw materials are heated in an oxygen deficient environment, which promotes the decomposition of organic matter and ultimately converts it into carbon. The diameter of carbon fiber filament yarn is generally between a few micrometers and several hundred micrometers, with high strength and rigidity. Due to its excellent structural and lightweight characteristics, carbon fiber filaments are widely used in various fields such as aerospace, automotive, and sports equipment.

High Modulus 12k 24k Carbon Fiber Rowing Yarn

Carbon fiber filament is a slender fiber composed of carbon-elements, usually made by high-temperature treatment (carbonization) of polymer precursors. The production process includes stretching and heat treatment of the fibers to arrange carbon atoms in an ordered structure within the fibers. The diameter of carbon fiber filaments is usually in the micrometer range, with high strength and rigidity, and exhibiting good heat resistance and chemical stability under certain conditions. Due to its manufacturing process and material characteristics, carbon fiber filament is widely used in various industrial and scientific research fields.

T300 T700 Carbon Fiber Filament Yarn For Sale

Carbon fiber yarn is essentially a continuous fiber bundle composed of thousands of extremely thin carbon fiber filaments bundled together, and is the most fundamental and important industrial intermediate form of carbon fiber materials. Its birth began with specific organic precursor fibers (the most common being polyacrylonitrile fibers, also known as PAN based, or asphalt based or adhesive based), which undergo a series of complex and precise high-temperature heat treatment processes, including pre oxidation (stabilized at 200-300 ° C in air), carbonization (expelling non carbonelements at 1000-2000 ° C in an inert atmospheres to form a disordered graphite structure), and possible graphitization (further optimizing crystal structure orientation and increasing modulus at higher temperatures such as 2500-3000 ° C).

After these rigorous conversion processes, the original organic fibers undergo a complete transformation, with a carbon content of over 90% in their elemental composition, forming carbon fiber monofilaments with unique properties.

High Quality T300 Carbon Fiber Roving Tow Yarn

Carbon fiber yarn is a fiber material with a carbon content of 95% or more. Carbon fiber is “soft on the outside and strong on the inside”, lighter than aluminum metal, but stronger than steel, and has the characteristics of corrosion resistance and high modulus, which is an important material in many applications. It not only has the inherent characteristics of carbon material, but also has the soft processability of textile fiber.

1k 3k 6k 12k Carbon Fiber Filament Yarn

Carbon fiber filament yarn is a high-performance carbon fiber product that significantly enhances and strengthens the properties of thermoset and thermoplastic composites. This includes products made for aerospace, automotive and several industrial applications. With a high tensile strength and tensile modulus, carbon fiber filament yarn is ideally suited for many processes, such as prepregging, filament winding, pultrusion, weaving and braiding.

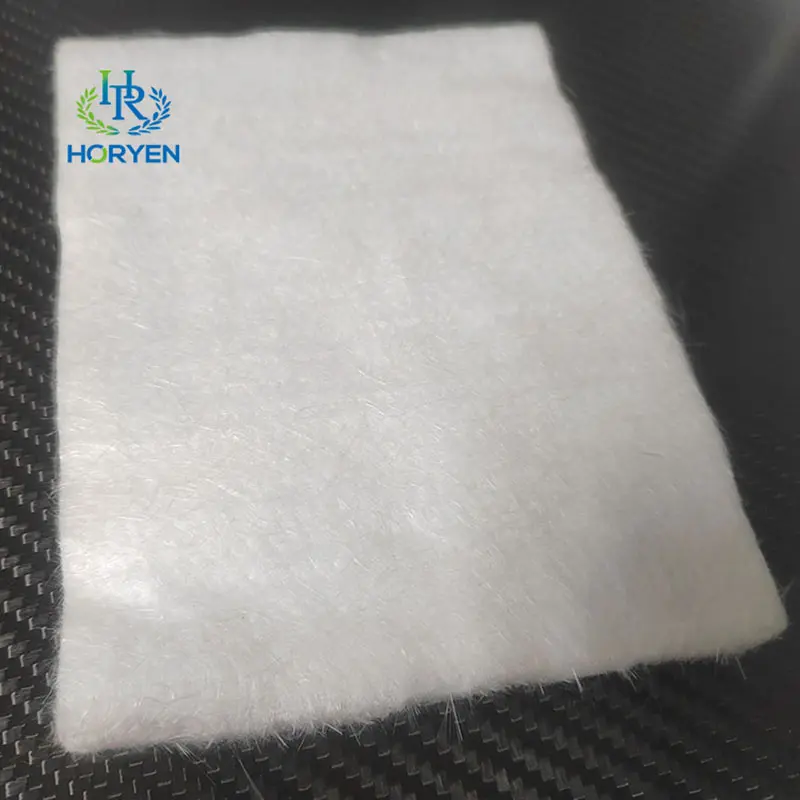

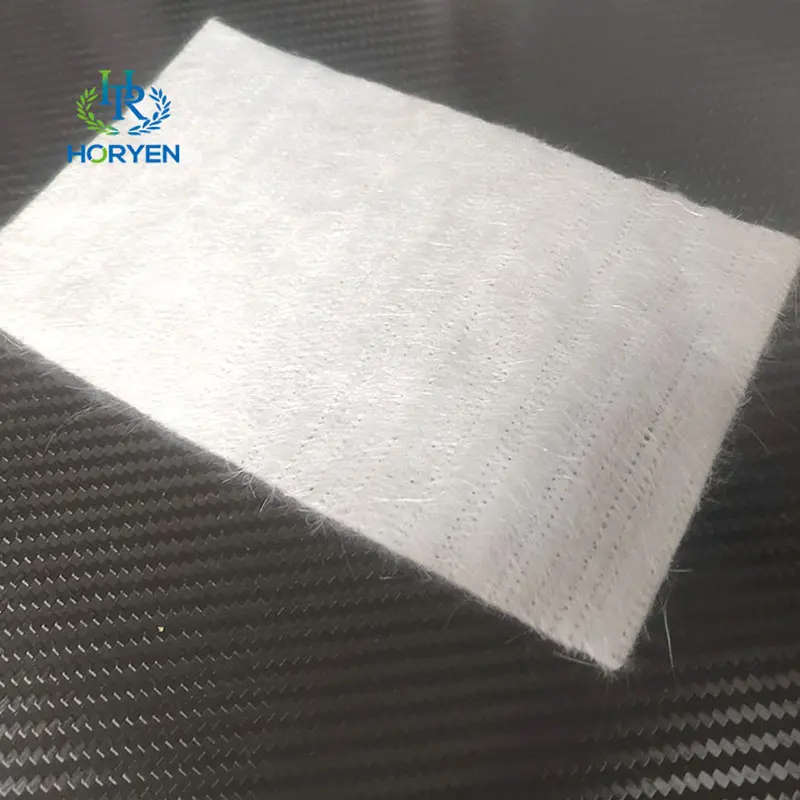

2mm Activated Carbon Fiber Felt For Air Purific...

Activated carbon fiber felt is a material made by carbonizing and activating adhesive fibers. This material undergoes specific processing to form a good bond between fibers, resulting in a felt like product with certain flexibility and strength. The production process usually involves uniformly distributing activated carbon particles within a carbon fiber matrix, and finally forming a felt with a specific thickness and density through pressing, heat treatment, and other methods. Activated carbon fiber felt has been widely studied for its potential applications in different fields, but its characteristics and uses will not be further discussed here.

High Quality Activated Carbon Fiber Mat For Sale

Activated carbon fiber mat is a mat like product made of activated carbon material. It is usually made of activated carbon fibers and processed through specific techniques to form a felt like structure with a certain thickness and flexibility. Activated carbon fiber mat has porous properties and can effectively adsorb impurities and pollutants in gases and liquids. In the production process, it has the characteristics of high adsorption performance, high breathability, good chemical stability, ease of processing, and renewability, so it has a wide range of applications in multiple fields. The manufacturing process of activated carbon fiber mat involves multiple technologies to ensure its good adsorption capacity and stable physical properties.

High Strength Activated Carbon Fiber Felt For A...

Activated carbon fiber felt is made from viscose fiber by carbonization and activation with large surface area, large pore volume and certain pore distribution. It has the features of large adsorption volume, fast adsorption speed, heat-resistance, acid resistance and alkaline resistance. The regeneration for activated carbon fiber is convenient. The adsorption capacity keeps almost same after many times of regeneration. It is widely used in solvent recovery, air purification, water treatment, gas mask, cigarettee filtration, nuclear air cleaning system, ozone elimination filter, gasoline vaporization protection for car, etc.

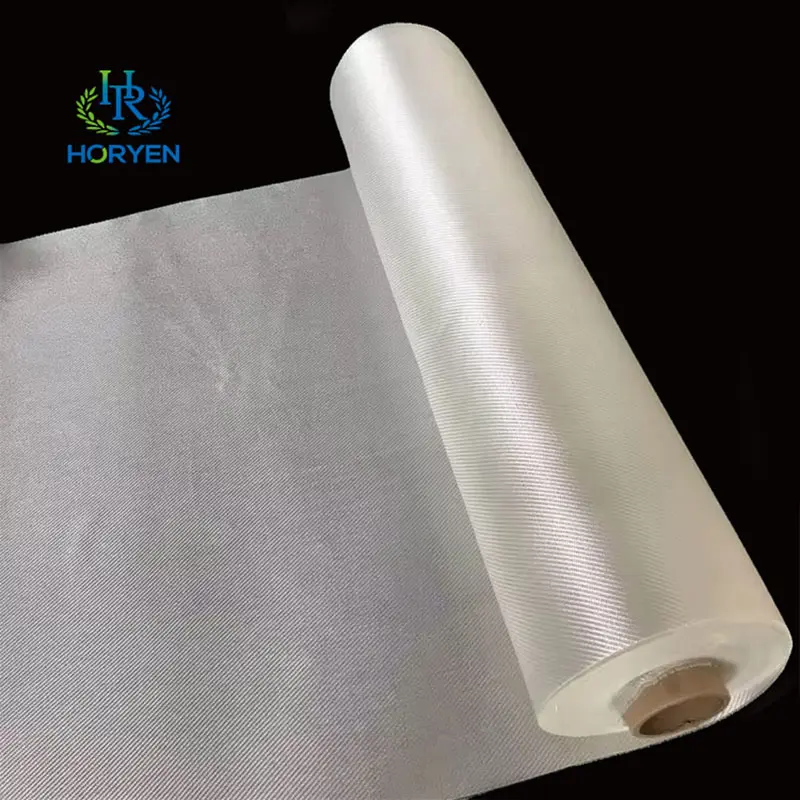

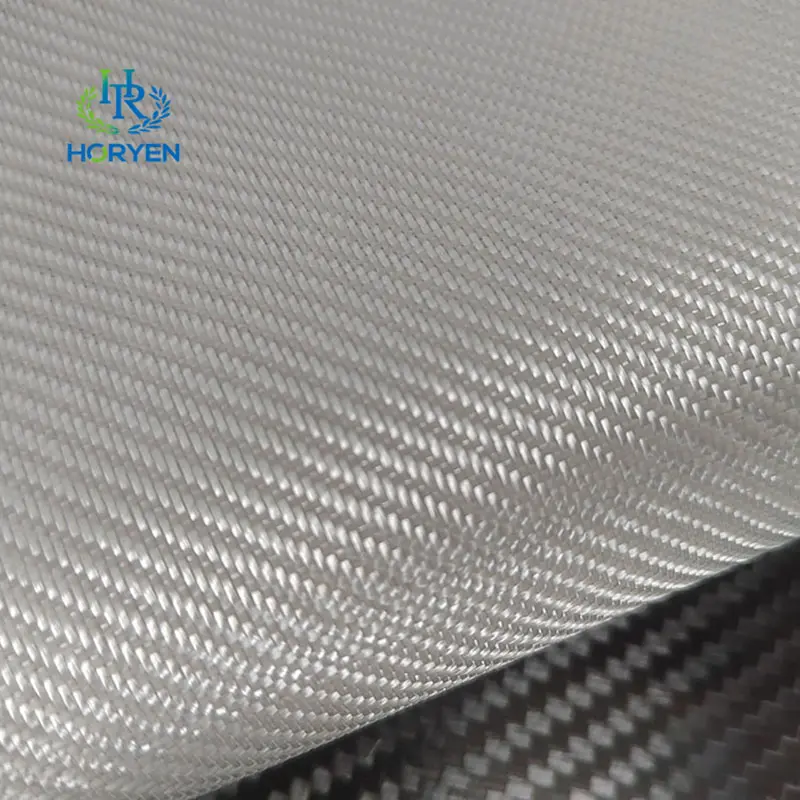

Hot Selling Twill Activated Fiber Cloth Fabric ...

Activated carbon fiber cloth is obtained by special treatment of carbon materials at high temperatures, which can significantly improve their specific surface area and adsorption performance. The manufacturing of activated carbon fiber cloth involves a series of complex chemical and physical processes aimed at enhancing its adsorption ability for pollutants in gases and liquids. The fiber morphology of this material gives it good flexibility and processability, making it suitable for various forms of applications.

Activated carbon fiber cloth, due to its unique structure, is commonly used in composites with other materials to enhance its performance, and has shown good results in treating harmful substances in gases and liquids. Due to its excellent physical and chemical properties, this material has received widespread attention in environmental governance and other related fields.