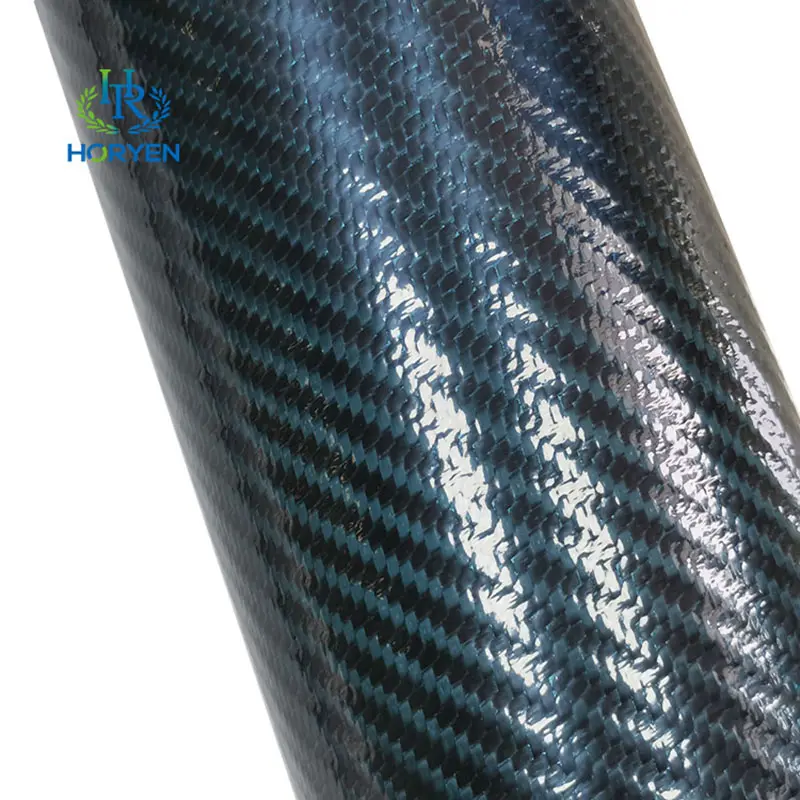

T700 Epoxy Resin UD Prepreg Carbon Fiber Cloth

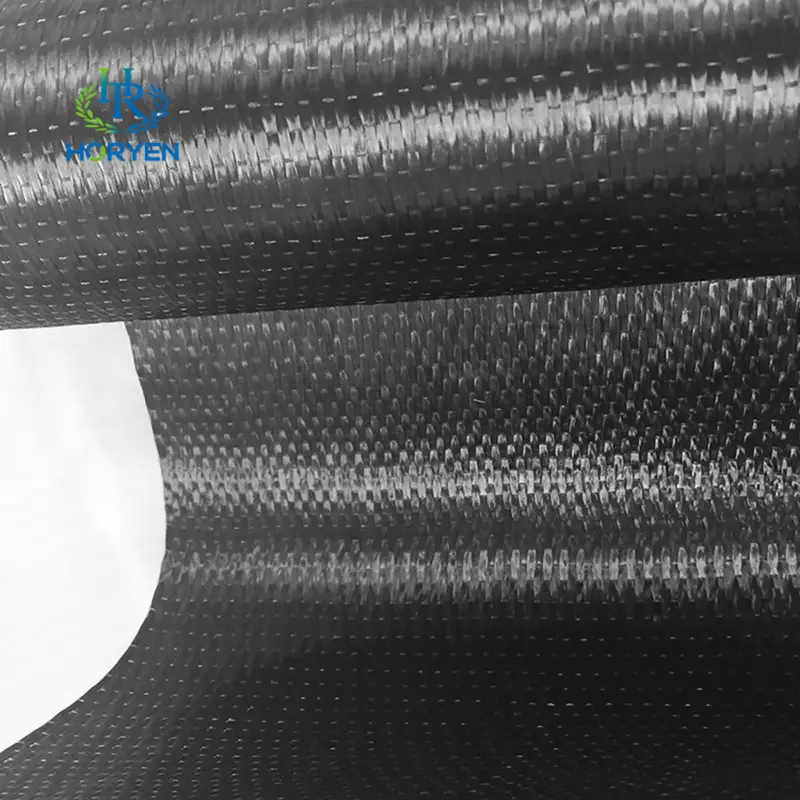

UD carbon fiber prepreg fabric is a composite material made by impregnating carbon fiber and resin in advance. Its structural feature is that all carbon fibers are arranged in the same direction to form a unidirectional fabric, which is usually laid in a specific direction to meet specific mechanical performance requirements.

Technologically, UD carbon fiber prepreg fabric is made by impregnating dried carbon fiber fabric into a resin matrix, which typically solidifies at room or high temperatures. In this way, the prepreg fabric has been pre treated with resin before use, which has the advantage of facilitating subsequent manufacturing and processing.

3K 12K Epoxy Resin Unidirectional Prepreg Carbo...

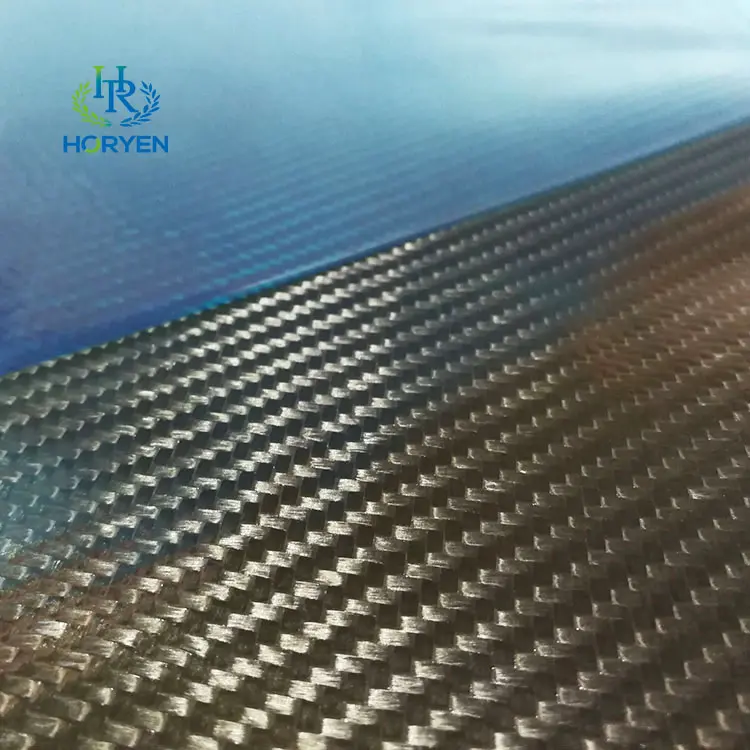

Unidirectional carbon fiber prepreg cloth is a composite material composed of high-strength carbon fibers arranged in a unidirectional structure. It is made by impregnating carbon fibers in resin, usually pre treated and kept in a certain humidity state for use in subsequent production processes. This material has the characteristics of lightweight, while providing superior strength and rigidity. The production process of unidirectional carbon fiber prepreg cloth usually involves accurate fiber arrangement and resin ratio to ensure the uniformity and stability of the material. This structure enables unidirectional carbon fiber prepreg cloth to exhibit specific directionality in mechanical properties, making it suitable for various manufacturing needs.

High Quality Epoxy Resin UD Carbon Fiber Prepre...

The carbon fibers used in prepreg carbon fabric are typically high-strength and high-modulus, which means they have excellent mechanical properties. The resin matrix, on the other hand, provides the fabric with structural integrity and helps bond the carbon fibers together.It is widely used in various industries, including aerospace, automotive, sports equipment, and marine, where high-performance materials are required.

Hot Sale 3k 200gsm Carbon Fiber Prepreg Fabric ...

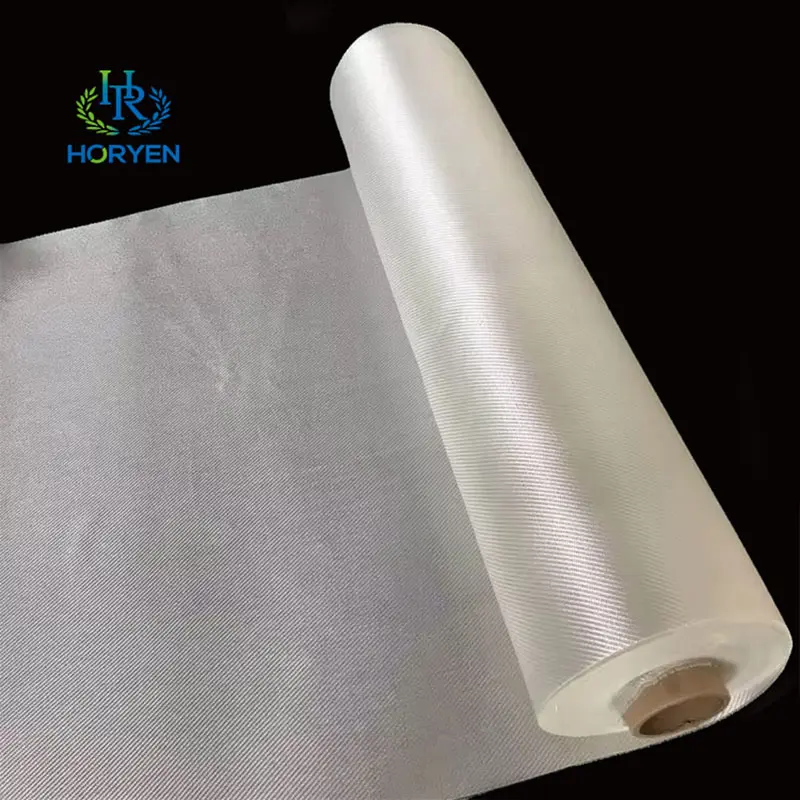

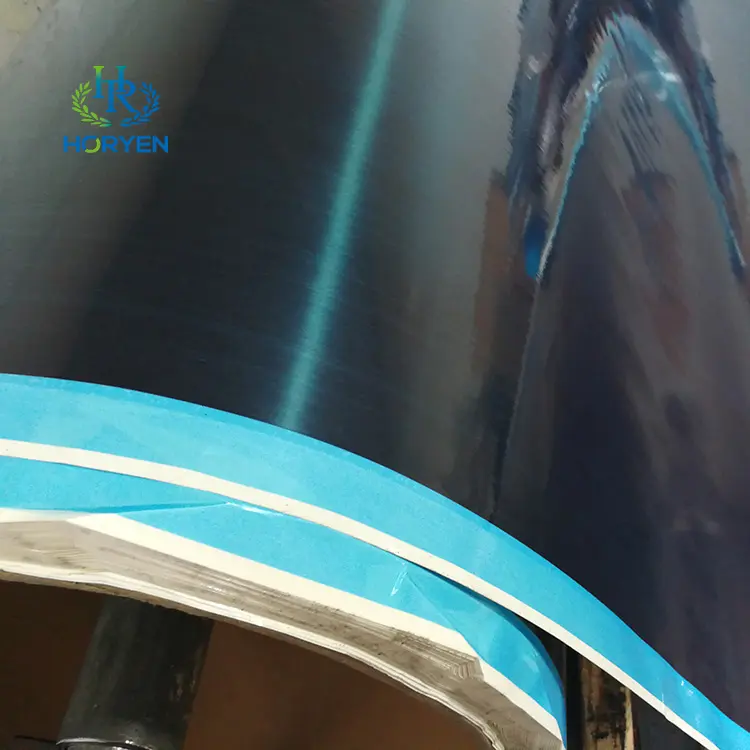

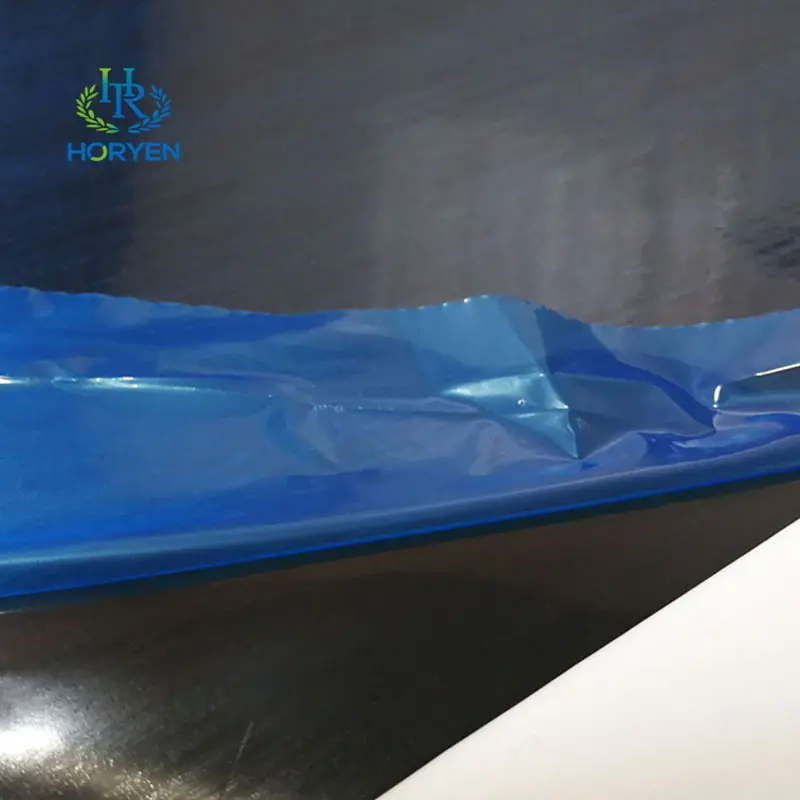

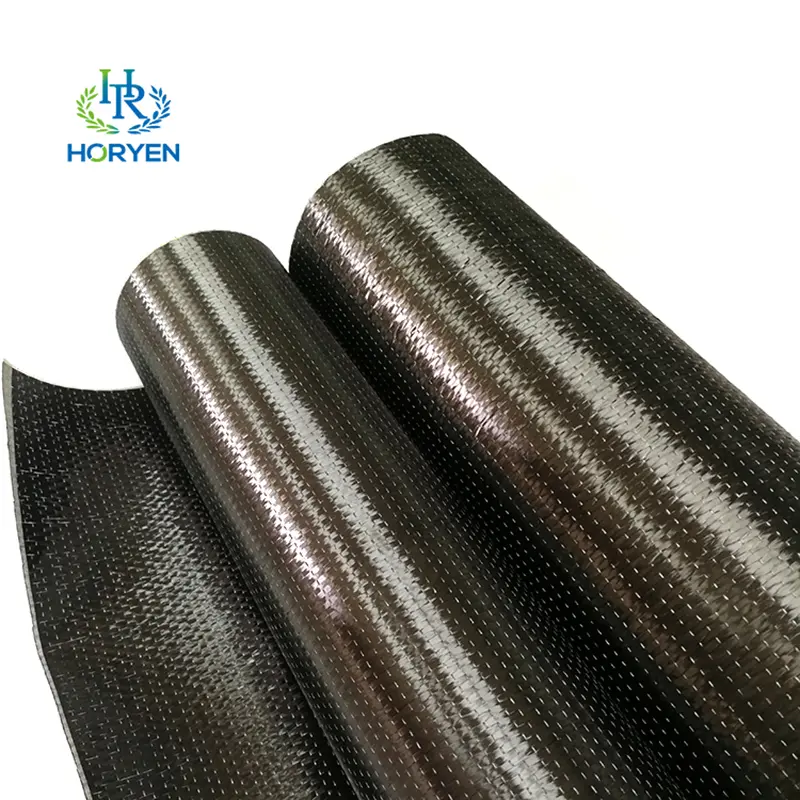

Carbon fiber prepreg fabric is a composite material mainly composed of carbon fiber and resin matrix. Its manufacturing process involves impregnating carbon fibers in pre treated resin, which ensures that the carbon fibers can uniformly and fully adsorb the resin. Prepreg carbon fiber fabric is usually provided in roll form and can be cut into different sizes as needed for subsequent processing and molding. From the perspective of chemical and physical properties, prepreg carbon fiber fabric has high strength, high modulus, and excellent corrosion resistance after curing, making it suitable for the manufacturing process of various composite materials.

High Quality 3k 240gsm Carbon Fiber Prepreg Fab...

Carbon fiber prepreg fabric is the important material for modern high-performance composite material manufacturing. It provides consistency, high quality, high efficiency, and the possibility of achieving ultimate performance for subsequent layering and curing processes by pre combining precisely controlled resins with high-performance carbon fibers in a controlled factory environment.

Its core value lies in the controlled, uniform, and optimized combination of the two core components of composite materials - high-strength, high modulus reinforcing fibers and matrix resins that provide bonding, load transmission, and protection - before entering the final molding process.

High Strength 3K 6K 12K Twill Prepreg Carbon Fi...

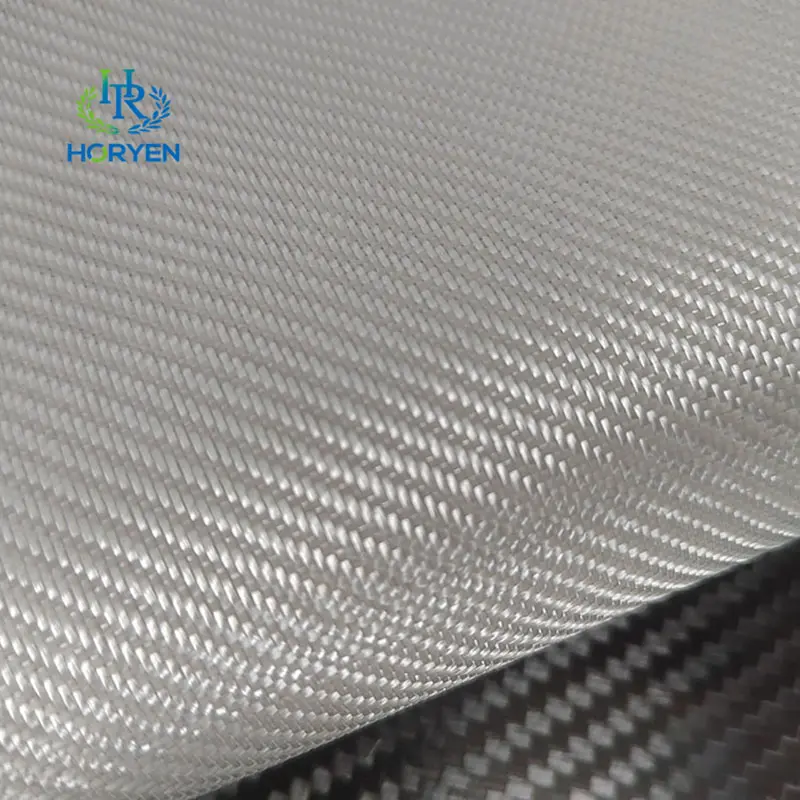

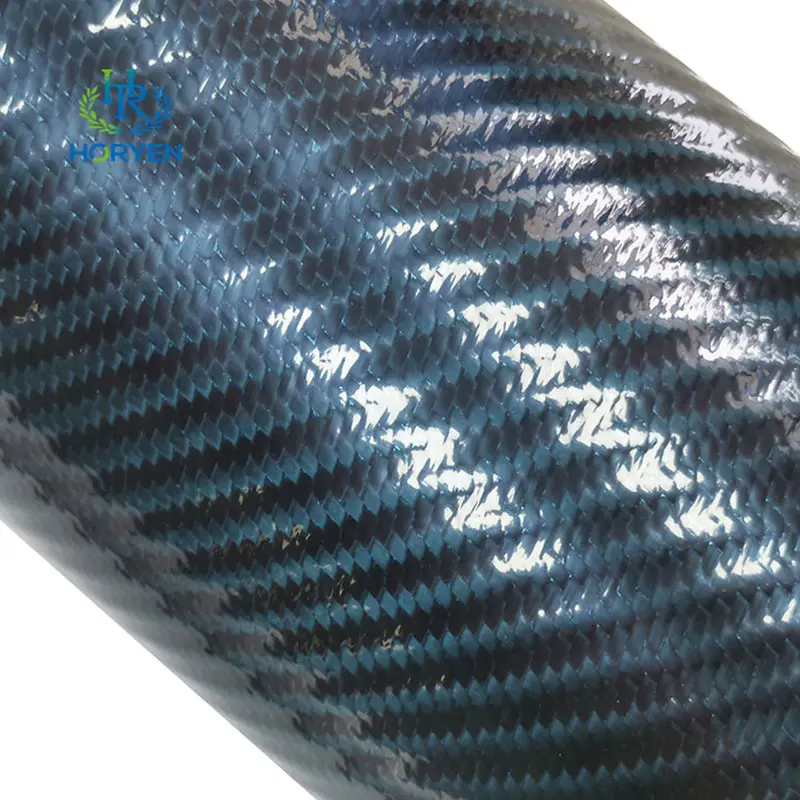

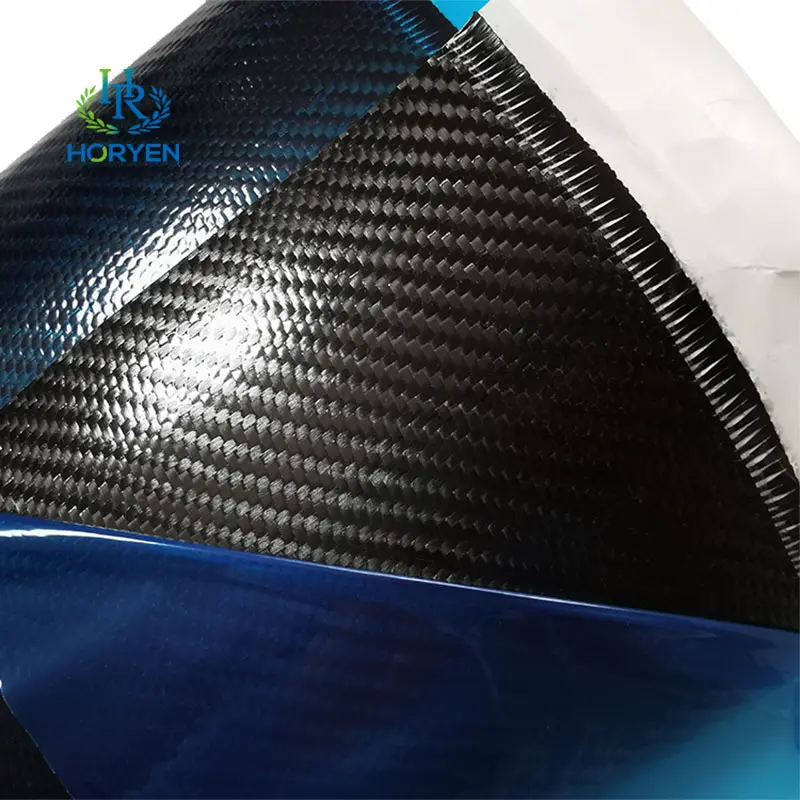

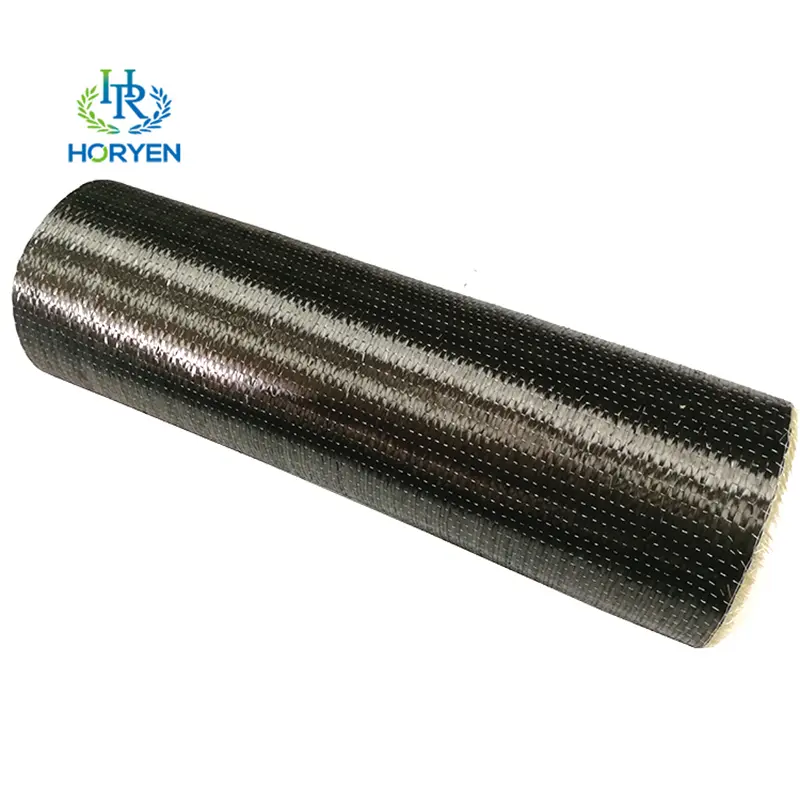

Carbon fiber prepreg fabric is a high-strength and lightweight composite material substrate made from high-performance carbon fiber bundles through accuracy weaving technology. Its core structure consists of thousands of carbon fiber monofilaments with a diameter of only 5-10 microns arranged in parallel or interwoven at specific angles into different weaving forms such as flat weave fabric and diagonal weave fabric. Then, uncured thermosetting resin is uniformly impregnated into the fiber gaps with precise resin content through precision coating equipment, and pre cured under strictly controlled temperature and tension environment to form a semi-finished state. This unique manufacturing process combines the high modulus characteristics of fiber reinforcement phase (tensile strength can reach 3.5-7GPa, elastic modulus 230-600GPa) with the impact resistance of resin matrix.

3K 200g 240g Epoxy Resin Prepreg Carbon Fiber F...

Prepreg carbon fiber cloth is a high-performance composite material made by carbon fiber and epoxy resin based materials. Prepreg Carbon Fiber Fabric has the advantages of light weight, high strength, corrosion resistance, wear resistance, etc., and is widely used in aerospace, automotive manufacturing, energy and other fields.

Carbon fiber prepreg fabric is made of epoxy resin and carbon fiber through the hot melt, coating, hot pressing, cooling, film, winding and other processing of composite materials, from the carbon fiber yarn, epoxy resin, release paper material composition.

12K T700 Reinforced UD Carbon Fiber Cloth For B...

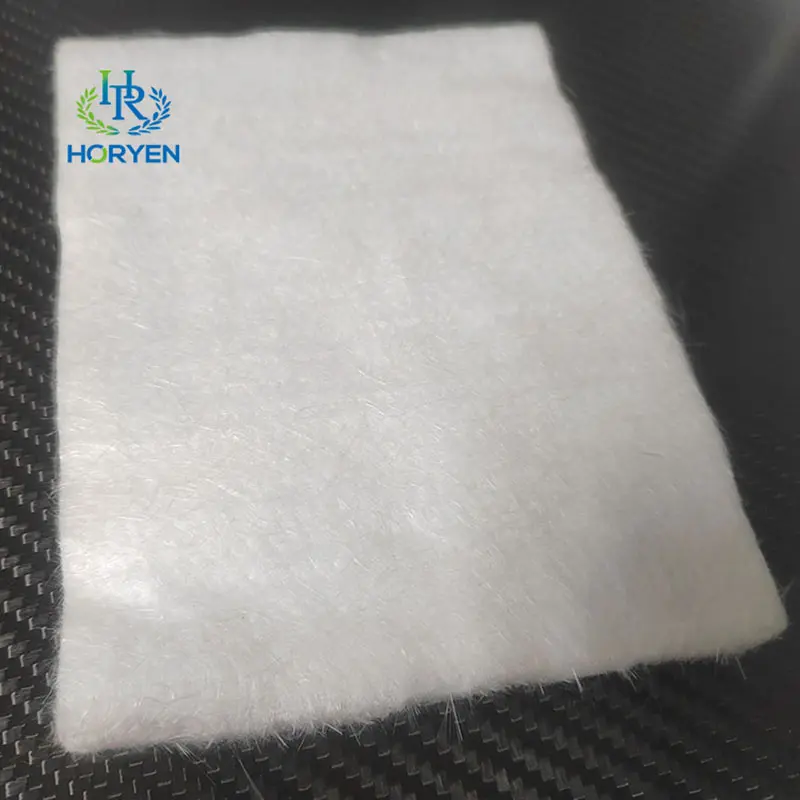

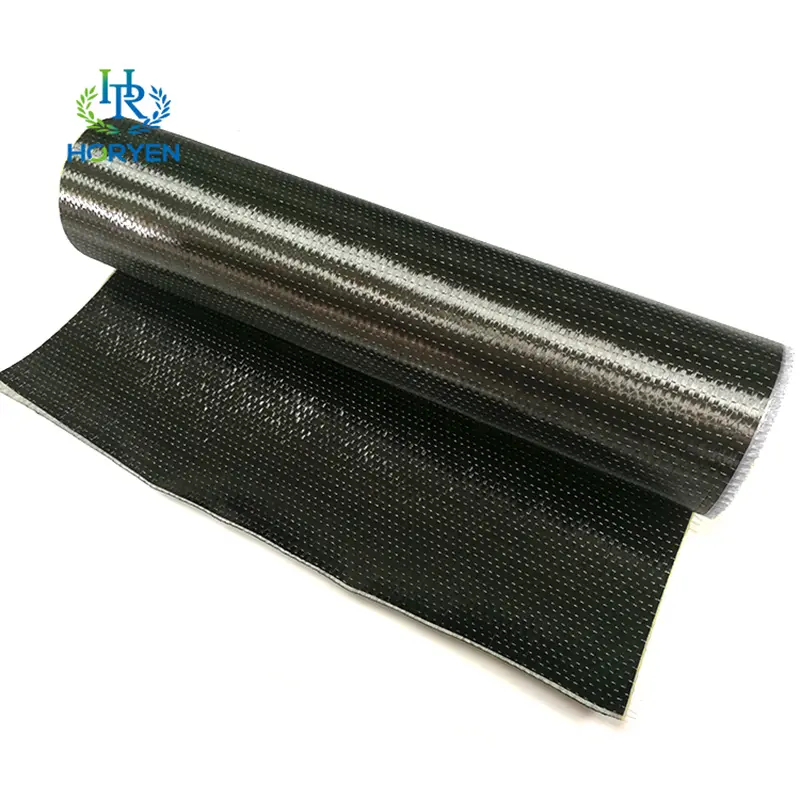

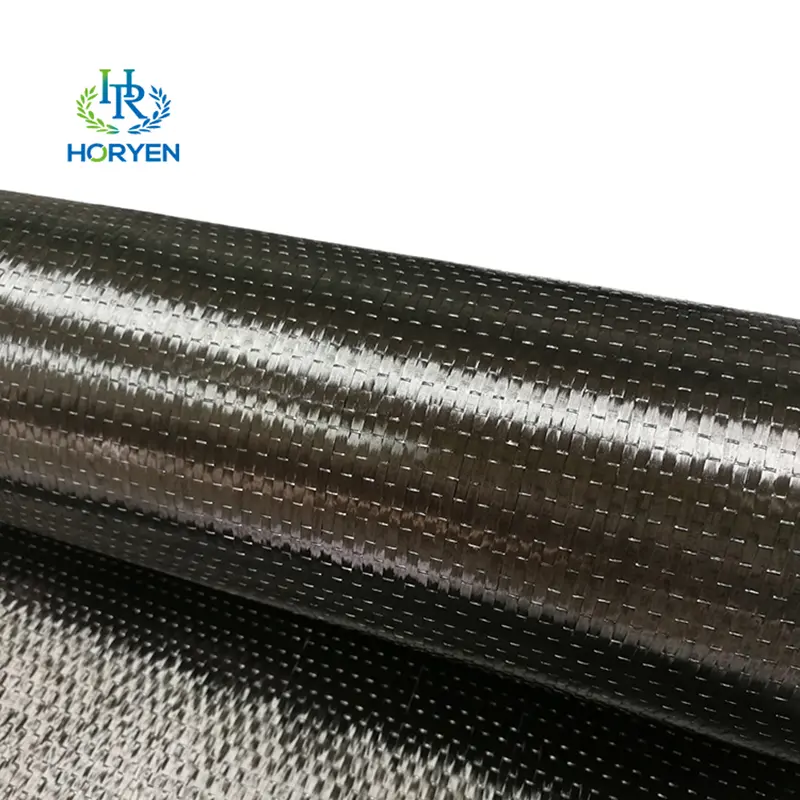

Carbon fiber UD cloth is a composite material made of carbon fiber, characterized by carbon fiber yarns arranged only in one direction. This design gives the material excellent strength and stiffness in that direction. Unidirectional fiber fabrics are usually made by stacking multiple layers of carbon fiber unidirectional fabrics to enhance the material's performance in multiple directions.

The production process of unidirectional fabric usually involves arranging and bonding carbon fiber yarns through special techniques to form a flat and tough fabric. Carbon fiber UD cloth is a fundamental material that provides important raw material support for the manufacturing of high-performance composite materials.

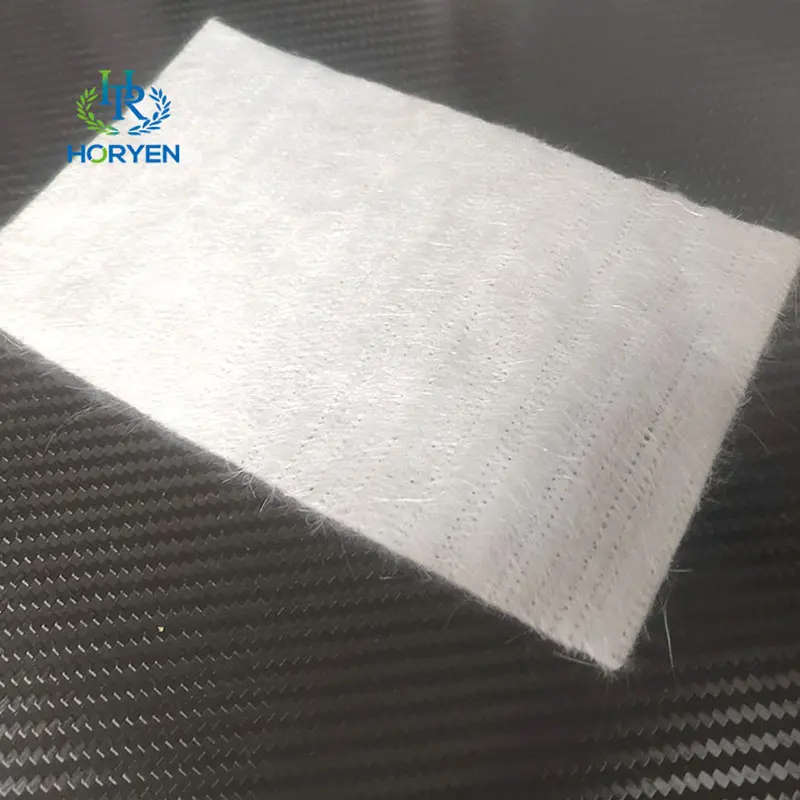

High Quality 12K 200g 300g UD Carbon Fiber Fabric

UD carbon fiber fabric is a composite material made of carbon fiber, which presents a unidirectional arrangement in structure. It is composed of multiple carbon fibers arranged in parallel in the same direction and bonded through matrix materials such as resin. This type of fabric is typically used to enhance the strength and rigidity of materials while maintaining their lightweight characteristics.

During the production process, the fibers of carbon fiber UD fabric can be arranged in the desired direction to meet different process requirements. Due to its specific fiber arrangement, this material typically exhibits excellent mechanical properties in one direction, while its performance in the vertical direction is weaker. According to the required application, UD fabric can be combined with other types of composite materials to improve the overall performance of the product.

High Strength 12k 300g Unidirectional Carbon Fa...

Carbon fiber unidirectional fabric is a high-performance composite material woven from unidirectional carbon fiber filaments through specific processes. Its characteristic is that carbon fiber filaments are arranged only in one direction, usually in the warp or weft direction of the fabric, which makes carbon fiber unidirectional fabric have very high strength and stiffness in a specific direction, and can withstand a large amount of tensile and compressive forces.

With the continuous progress of science and technology and the rapid development of the carbon fiber cloth industry, the production process of unidirectional carbon fiber cloth is constantly improving, the performance is constantly improving, and the cost is constantly decreasing. In the future, unidirectional cloth is expected to be applied in more fields, such as new energy, environmental protection, etc. At the same time, with the continuous improvement of people's requirements for material performance, the research and innovation of unidirectional cloth will also be continuously promoted to meet the new demands and challenges of the market.

12K 200g UD Carbon Fiber Cloth For Concrete Con...

Carbon fiber cloth is a high-strength, high modulus composite material widely used in aviation, automotive, sports equipment and other fields. In carbon fiber cloth, unidirectional and bidirectional are two common types of fiber cloth.

UD carbon fiber cloth refers to the arrangement of fibers in only one direction, that is, only longitudinal or transverse fibers. The unidirectional characteristic of carbon fiber cloth is that it has very high strength and stiffness, and can withstand a large amount of tensile and compressive forces. The unidirectional application of carbon fiber cloth is very extensive, and it can be used to make airplanes, cars, ships, sports equipment, and so on.

Hot Selling 12K 200g 300g 400g 600g UD Carbon F...

Carbon fiber unidirectional fabric is a high-performance composite material woven from unidirectional carbon fiber filaments through specific processes. This material has very high strength and stiffness in specific directions, and can withstand a large amount of tensile and compressive forces. The fiber arrangement of unidirectional carbon fiber cloth is usually only in one direction, usually the warp or weft direction, which makes its performance particularly outstanding in that direction.

The main characteristic of carbon fiber unidirectional fabric is the singularity of fiber direction, which has the advantages of high strength, high modulus, lightweight, etc. It is widely used in aerospace, automotive industry, sports equipment and other fields.