Abrasion Resistant Good Quality 3k Tube Carbon ...

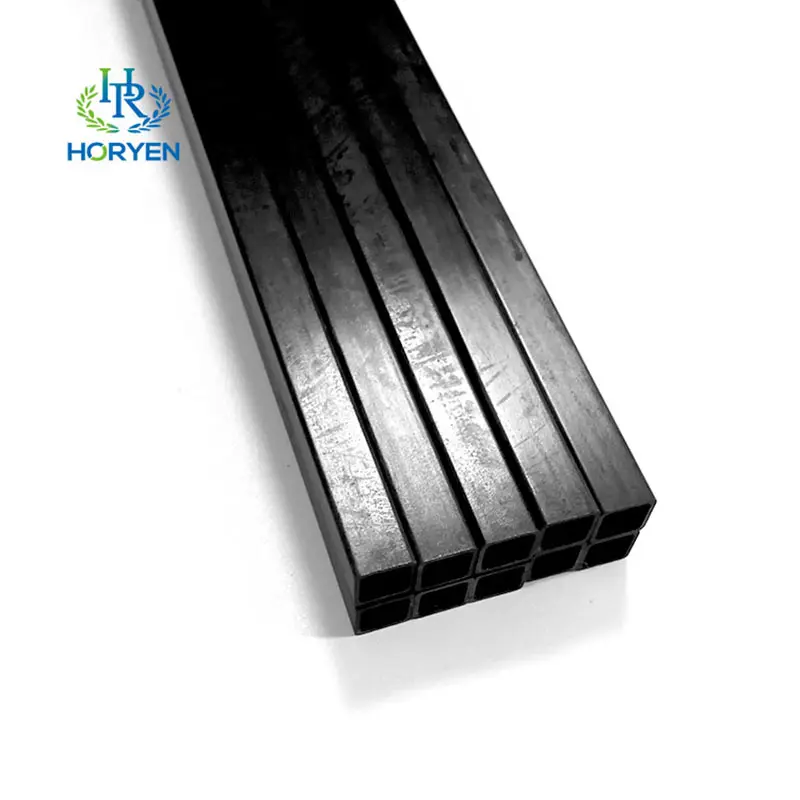

Carbon fiber square tube is a square section tubular product mainly made of carbon fiber as the raw material. It is composed of multiple carbon fiber layers compounded by a resin matrix, forming a lightweight and tough structure. Carbon fiber has excellent mechanical properties and corrosion resistance, so advanced composite material technology is usually used in the production process of carbon fiber square tubes to ensure their uniformity and strength. They can be customized according to different sizes, thicknesses, and strength requirements to meet the needs of various projects.

High Strength CFRP Pultruded Square Carbon Fibe...

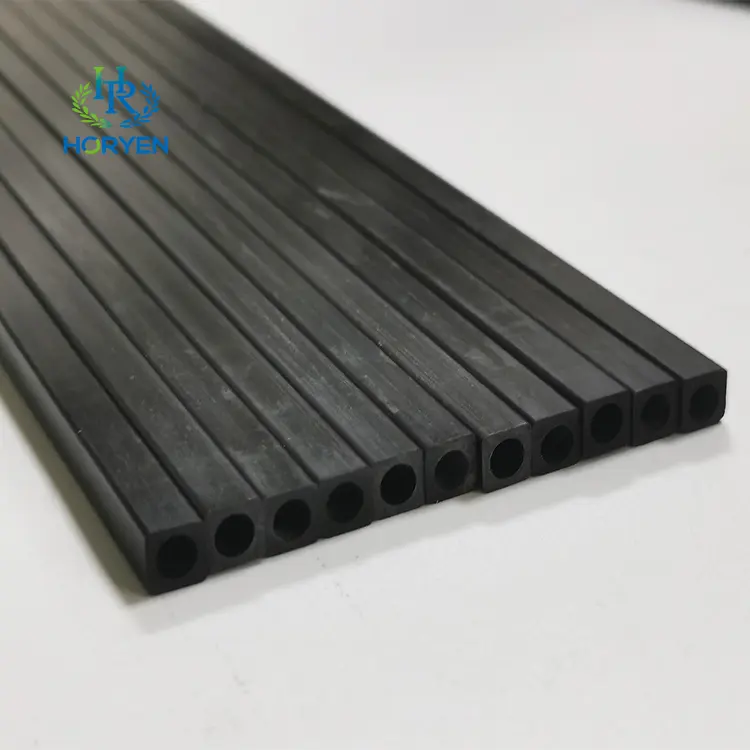

Pultruded carbon fiber tube is a composite material tube manufactured through pultrusion molding process, mainly composed of high-strength carbon fiber and resin matrix. The production process usually involves pulling carbon fiber bundles and resin materials into a heated mold at the same time, and the resin solidifies inside the mold to form a sturdy pipe.

The advantage of this process is that it can effectively control the density and strength of the product, while ensuring a certain degree of shape and dimensional accuracy. The general structure of pultruded carbon fiber tubes can be a hollow cylindrical shape, or other cross-sectional shapes can be designed according to requirements. By adjusting the arrangement of fibers and the ratio of resin, different physical and mechanical properties can be achieved to meet various process requirements.

3mm 6mm 8mm Pultruded Carbon Fiber Square Tube

Pultruded carbon fiber tube is a composite material tube manufactured through pultrusion process, mainly composed of carbon fiber and resin. In the manufacturing process, carbon fibers are first soaked in resin and then extruded through molds. This process ensures that carbon fibers are evenly distributed inside the pipeline, thereby forming pipes with high strength and lightweight characteristics.

The structure of extruded carbon fiber tubes is relatively complex, usually with high composite material strength and rigidity. Due to the properties of their composite materials, multiple diameters and wall thicknesses can be chose to meet different design requirements. By arranging different carbon fiber and resin combinations, the performance of the pipes can be adjusted to suit specific usage scenarios.

Lightweight Pultrusion Carbon Fiber Tubing For ...

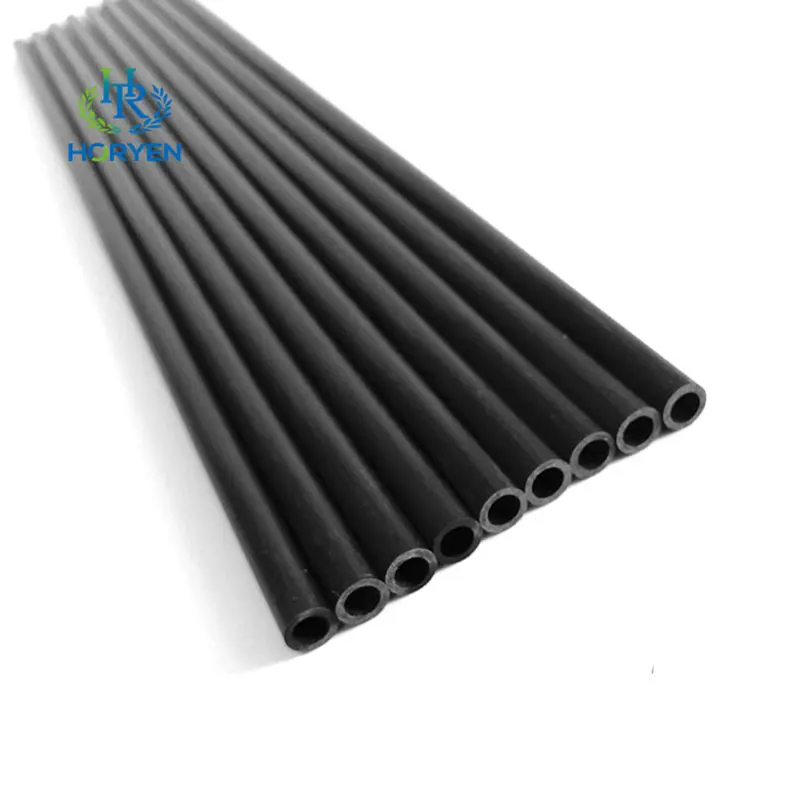

Pultruded carbon fiber tubing is a composite material pipe manufactured through pultrusion process. This process involves extruding carbon fiber prepreg through a mold, which can achieve efficient production and ensure product uniformity and consistency. Pultruded carbon fiber tubes have high strength and rigidity, and resin is usually used as the matrix in the manufacturing process to combine carbon fibers and resin together to form composite materials. This type of pipe can adjust the fiber arrangement and resin ratio as needed during the production process to meet different production requirements.

Custom Lightweight Hollow Carbon Fiber Pultrusi...

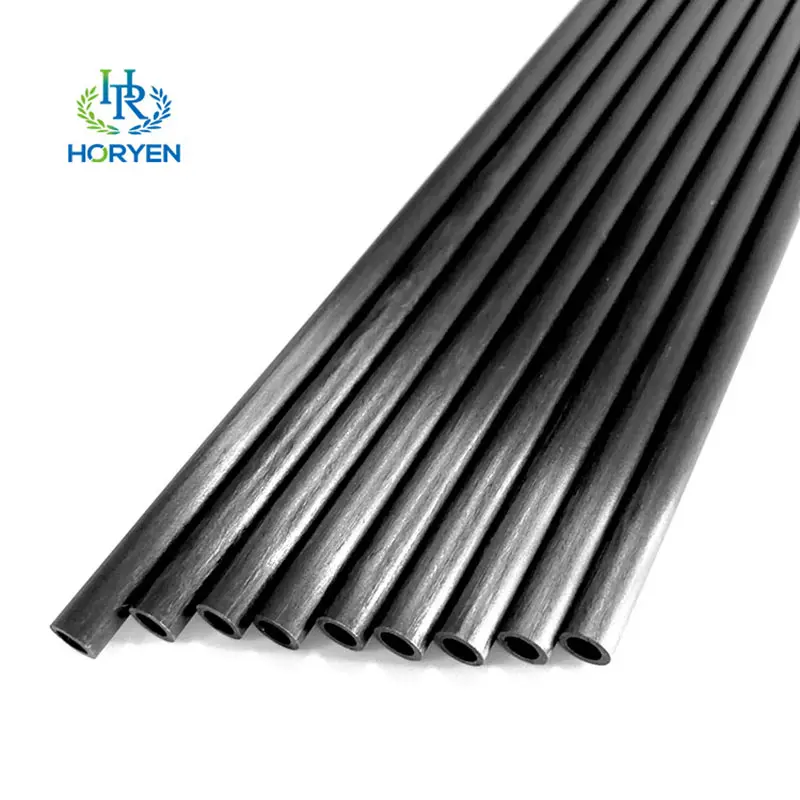

Carbon fiber pultrusion tubing is a type of pipe produced through pultrusion technology, mainly composed of carbon fiber reinforced materials. The production process of this type of tube involves mixing carbon fiber with base materials such as resin, and then forming the desired tubular structure through continuous extrusion. Pultrusion process is an efficient molding method, which has the advantage of producing long products with uniform structure and excellent physical properties. Carbon fiber pultrusion tubes are widely used in multiple fields due to their excellent mechanical properties and lightweight characteristics.

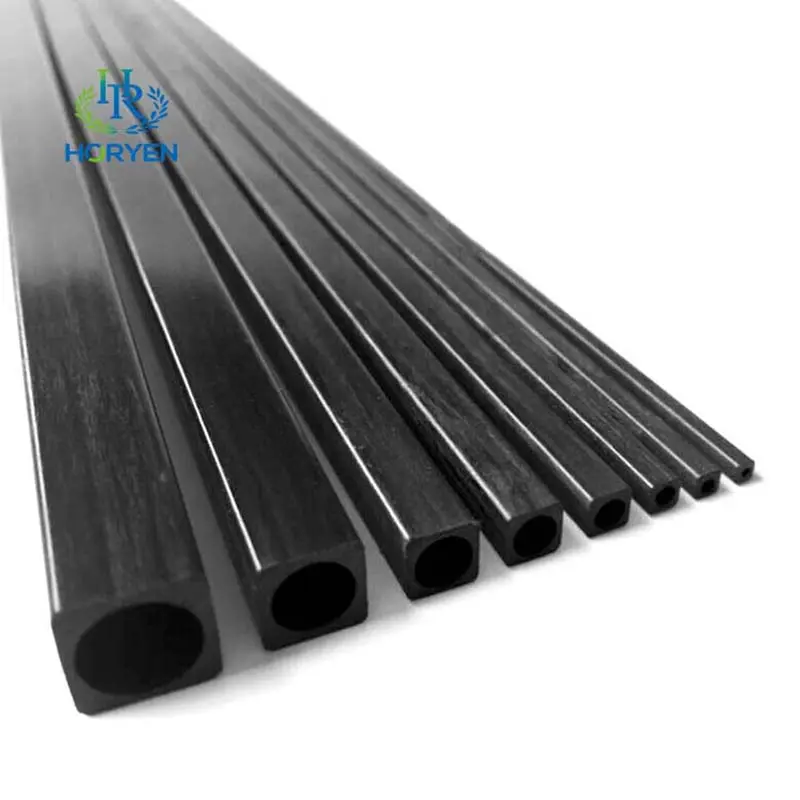

3mm 7mm 9mm Round Pultruded Carbon Fiber Tube

Carbon fiber tapered tube is a tubular product produced by the extrusion process of carbon fiber materials. Pultrusion process is a process of drawing and shaping carbon fiber bundles pre impregnated with resin through a mold. This process can control the fiber arrangement and fiber content of the material, thereby achieving excellent mechanical and physical properties.

During the production process, carbon fiber bundles are pulled through the mold, and the resin solidifies in this process, forming a sturdy and lightweight pipe. This process can not only produce carbon fiber tubes of various sizes and shapes, but also customize the performance and thickness of materials according to requirements.

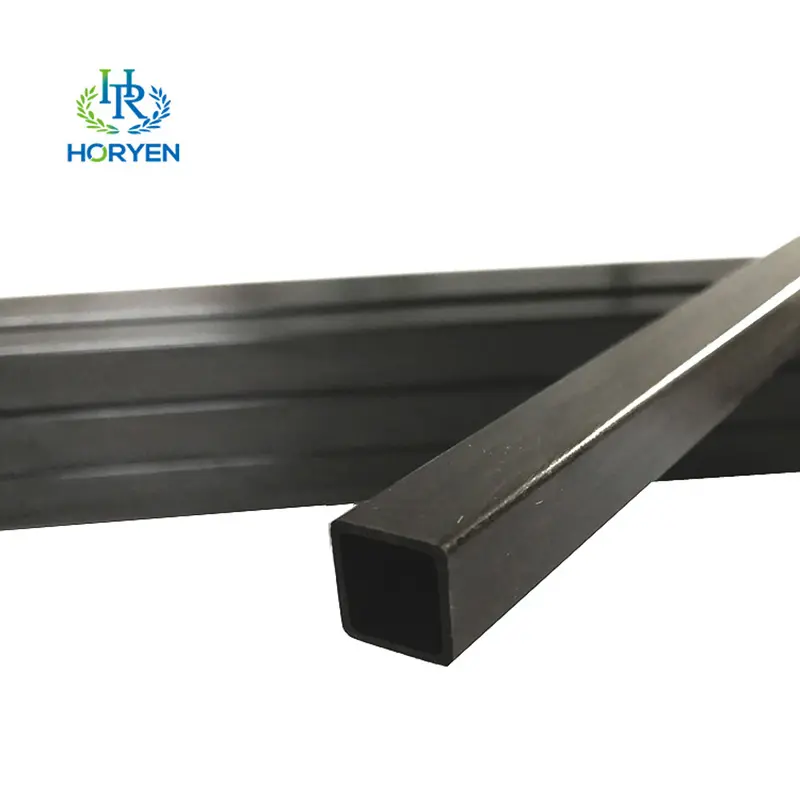

High Modulus Pultrusion Carbon Fiber Square Tub...

The process of pultrusion molding is also an important process for making carbon fiber tubes. It involves impregnating carbon fibers and fiber fabrics with resin and extruding them into a basic shape under external force, followed by corresponding heat curing molding and cutting according to size. Pultrusion molding is a process of adding carbon fiber tubes into molds through pultrusion, and then curing them into carbon fiber tubes. In addition, this molding process is also used for some carbon fiber products such as rods, I-beams, and grooves.

High Quality Round Pultruded Carbon Fiber Tubing

Pultruded carbon fiber tube is a high-performance tubular composite material component produced through a continuous manufacturing process called "pultrusion molding". The core of this process is to precisely guide continuous carbon fiber bundles (known as rovings or bundles) pre impregnated with resin (usually thermosetting resins such as epoxy, polyester, or vinyl ester, or thermoplastic resins) through a meticulousness heating mold with a specific tubular cross-sectional shape.

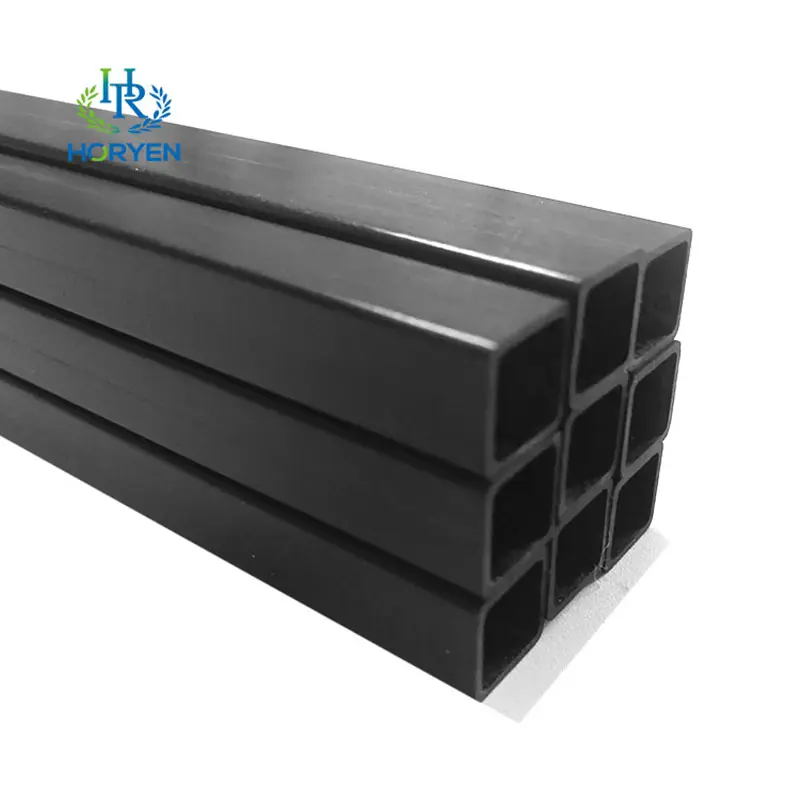

High Strength CFRP Pultruded Square Carbon Fibe...

Carbon fiber pultruded square tube is a structural material manufactured using pultrusion technology, mainly composed of carbon fiber and its resin matrix composite. This type of square tube is formed by immersing carbon fiber in resin under high temperature and pressure conditions, and then extruding it through a mold to form a solid pipe with a certain cross-sectional shape. The manufacturing process ensures the uniformity and high strength of the material, allowing it to maintain stable physical and chemical properties under certain temperature and humidity environments.

The square tube has a smooth appearance and the surface treatment can be customized according to customer needs. Due to its excellent processing performance and lightweight characteristics, carbon fiber extruded square tubes can be flexibly processed according to different length, thickness, and other requirements during production to meet multi-dimensional manufacturing needs.

Square Pultruded Carbon Fiber Tube for Rc Planes

The main raw material for pultruded carbon fiber square tubes is carbon fiber, which is a square tube produced through extrusion technology. The manufacturing process of this product includes mixing carbon fiber with resin, forming a specific square cross-section through heating and extrusion, and then curing and molding. Due to the high strength and low density characteristics of carbon fiber, this square tube can maintain accurate dimensions and uniform structure during production, giving it excellent physical properties. The surface of carbon fiber pultruded square tube is usually smooth and has a good appearance, which can meet the diverse needs of different fields. During its production process, batch production and standardization can be achieved to ensure product consistency and stability.

Light Weight Round Carbon Fiber Pultruded Tubes

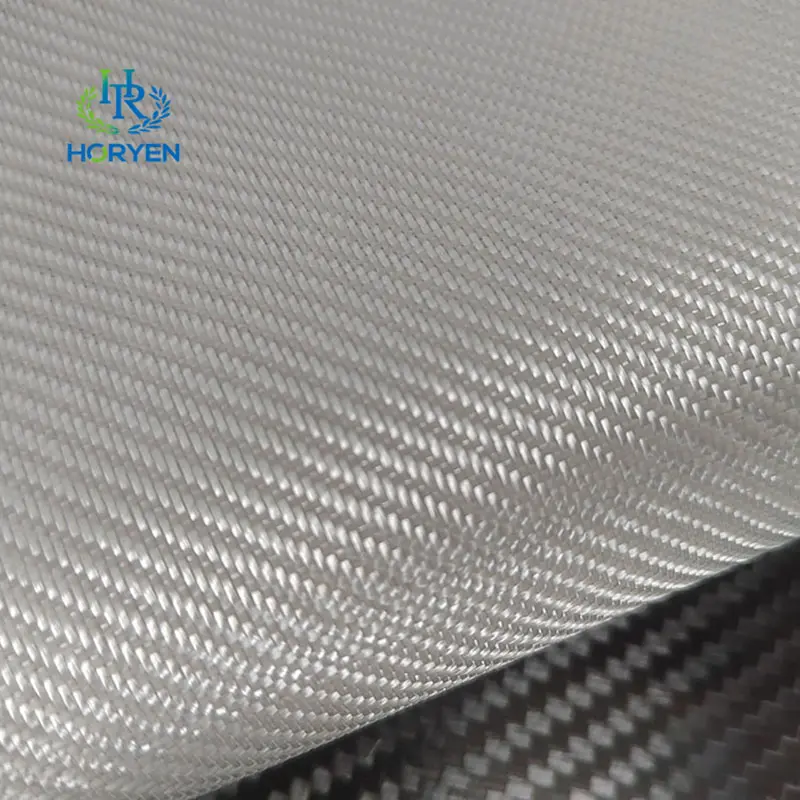

Pultruded unidirectional tubes are manufactured through a pultrusion process. It's a great choice for reinforcing structures.The pultrusion process guarantees an accurate design and measurement control, perfectly aligned fibers and a smooth surface.

Instead of injection molding the plastic material, the pultrusion process continuously pulls fibers from rolls, which are then wetted with a matrix material . Subsequently, they are pulled through a heated die, which determines the shape of the profile.

The technology is suitable for all types of fibers or a combination of fiber types. A high fiber-volume content is feasible, which makes it possible to reach a high specific rigidity and strength of the profiles.

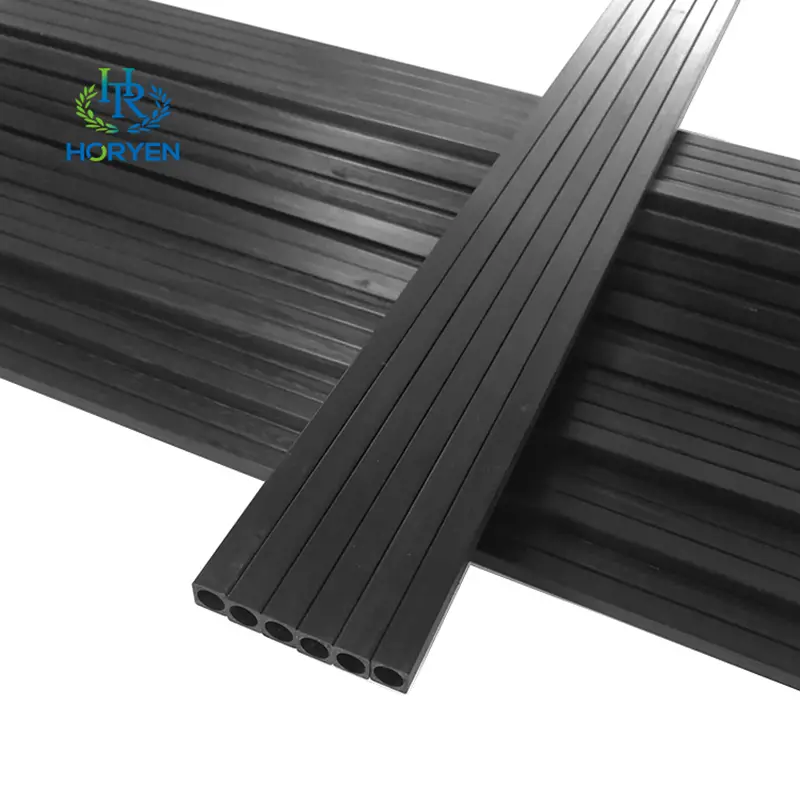

Custom Hollow Pultrusion Carbon Fiber Square Pr...

The process of pultrusion molding is an important industry in the production of carbon fiber tubes. It utilizes the external force to impregnate carbon fibers and fiber fabrics into a basic shape through resin impregnation and then extrusion, followed by corresponding heating and solidification molding. Pultruded carbon fiber tubes are lightweight, high-strength, with high specific strength and modulus.