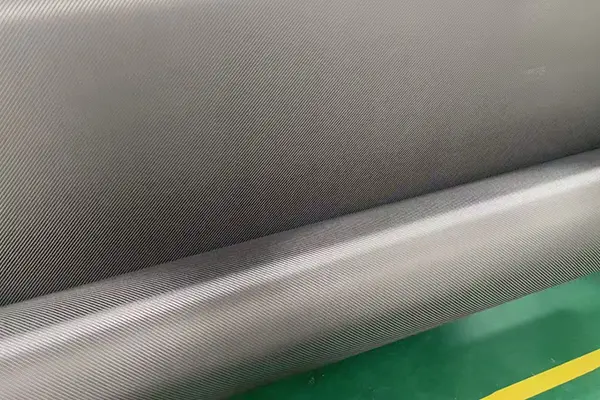

Construction Reinforcement 0 90 Degree Carbon Fiber Biaxial Fabric

Product Feature

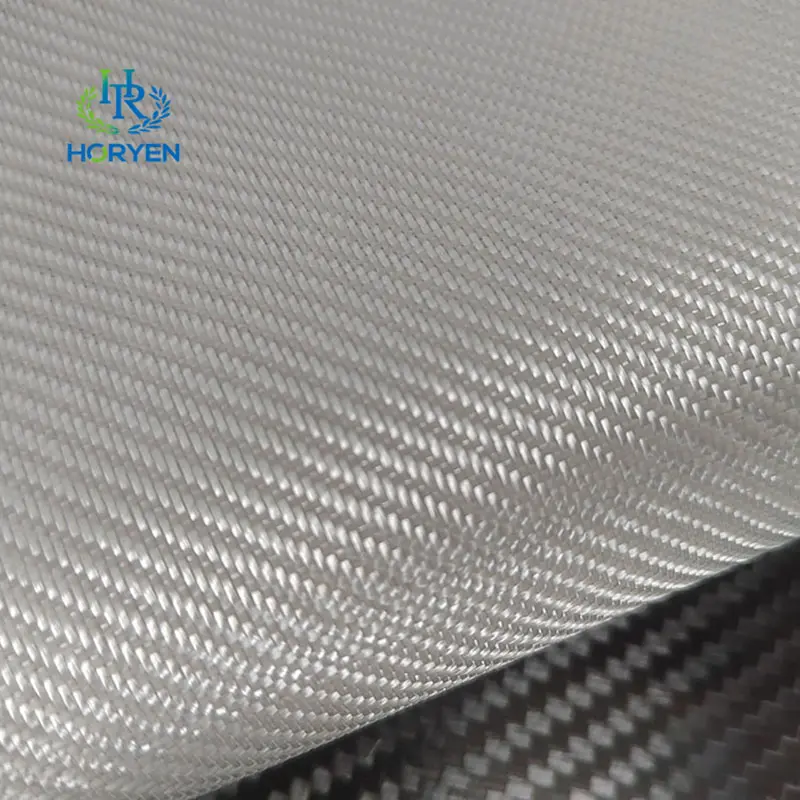

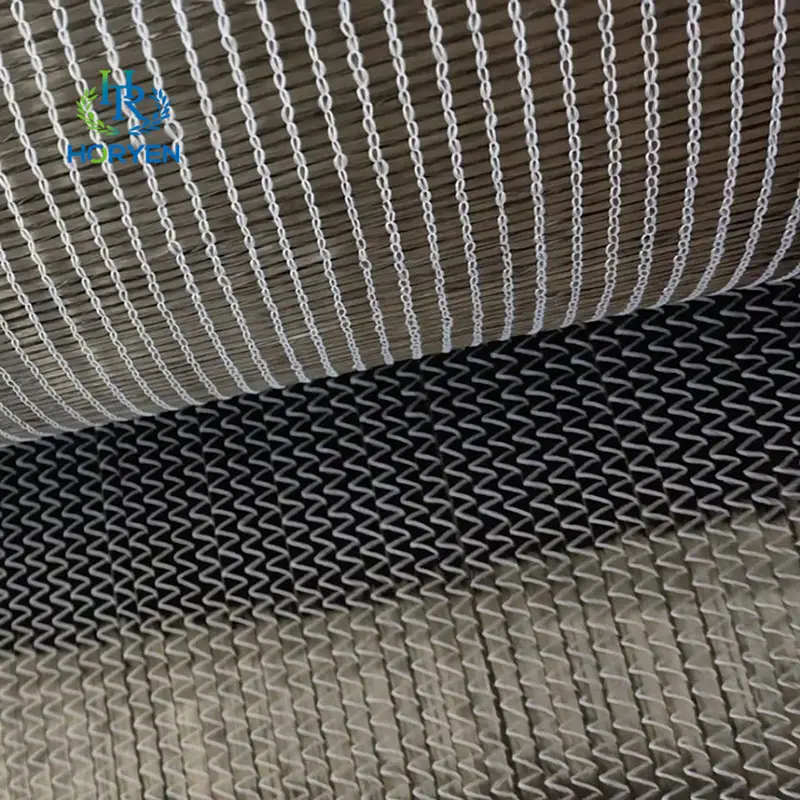

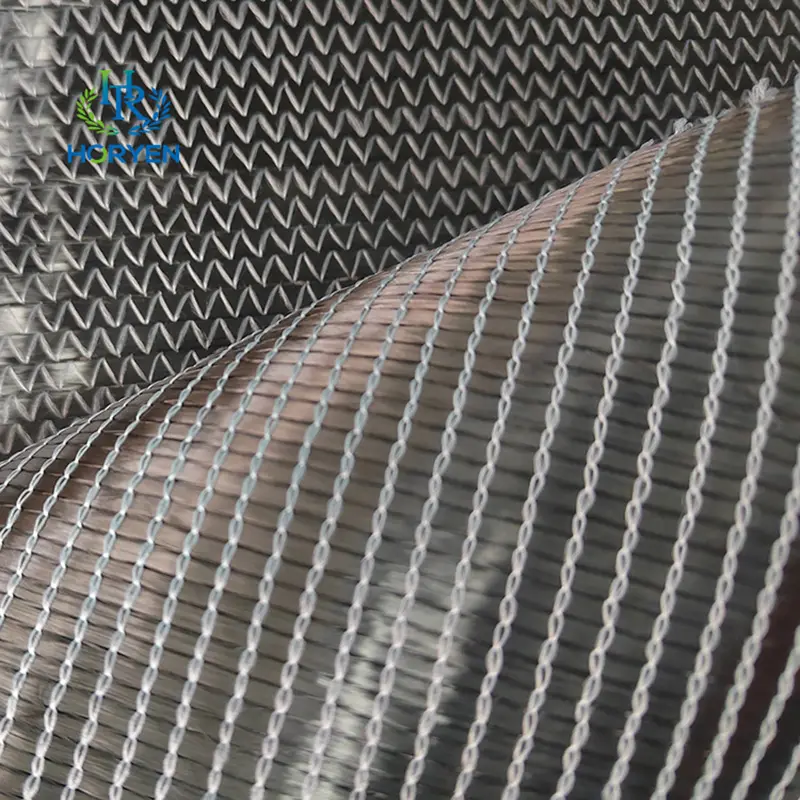

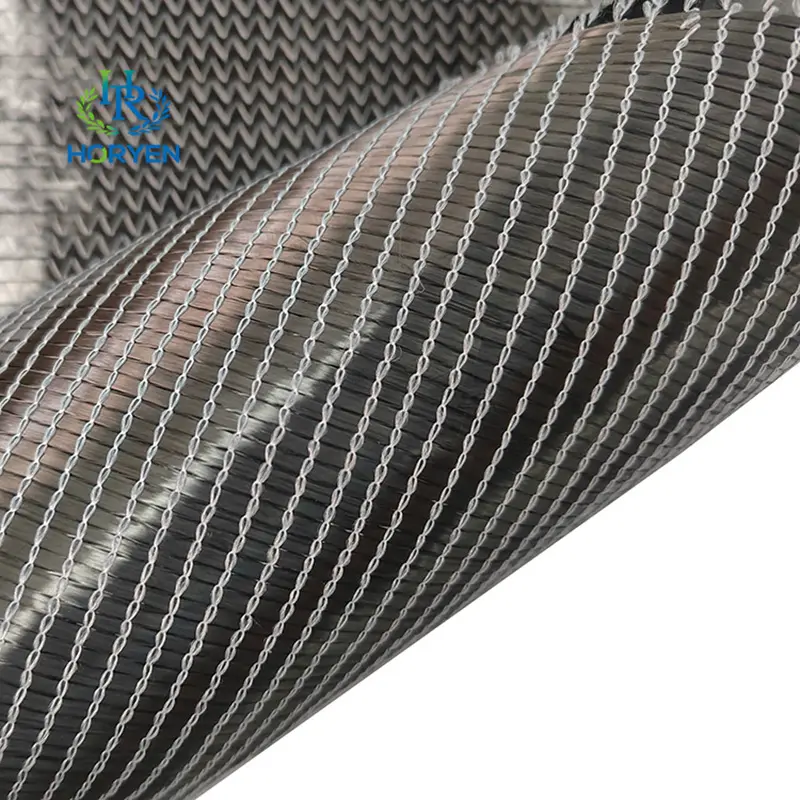

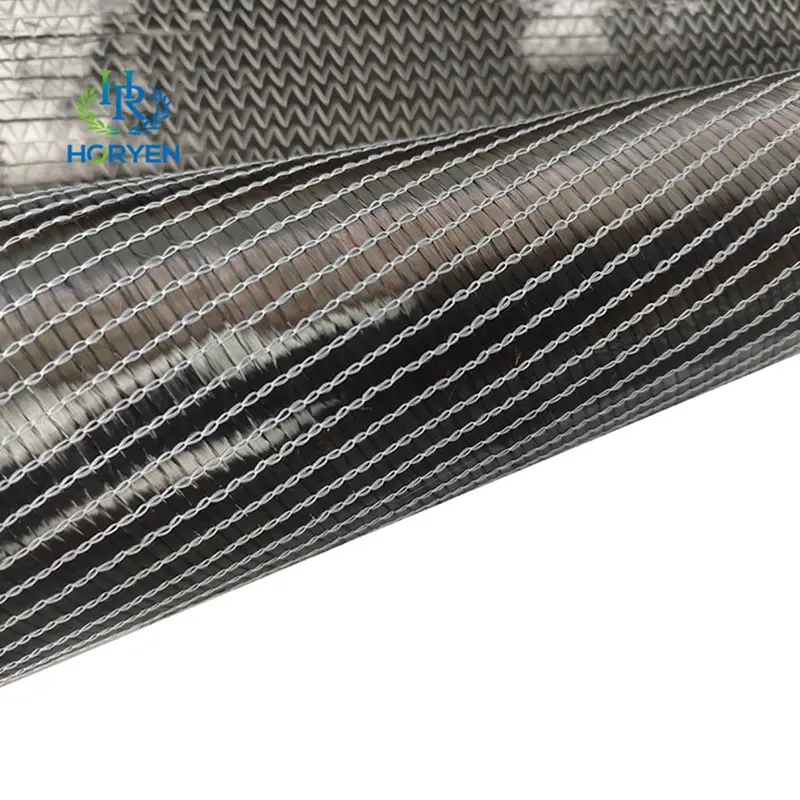

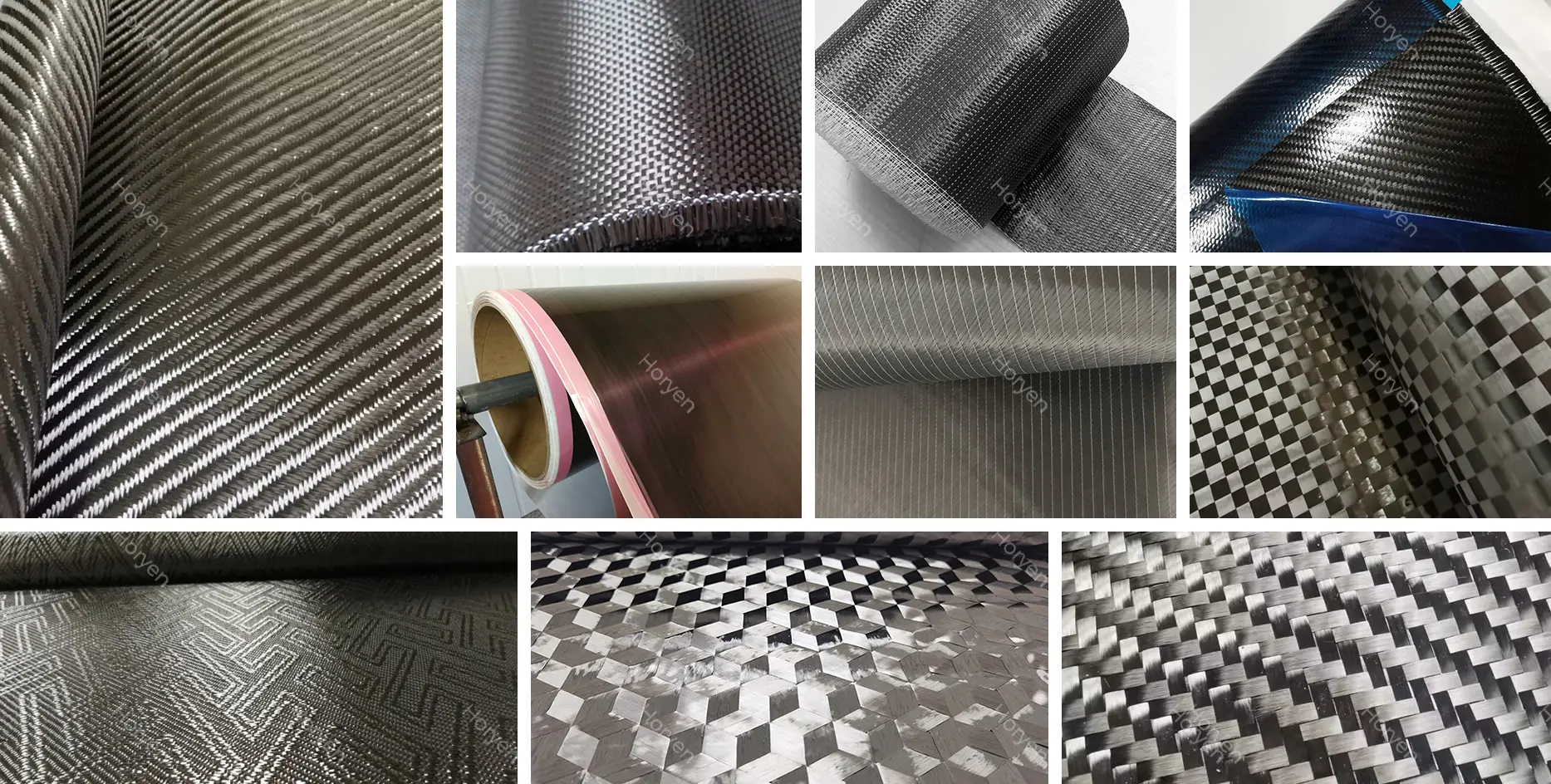

●Biaxially oriented arrangement: Carbon fiber bundles are spread in parallel along two mutually perpendicular (or specific angle) directions in the fabric, forming a regular grid like structure (such as 0 ° and 90 °).

●Bidirectional balanced strength: Provides uniform mechanical properties (tensile and compressive) in two main directions, avoiding the anisotropic weaknesses of unidirectional fabrics.

●Lightweight: With a density only 1/5 of steel, its strength is several times higher.

●Fatigue and corrosion resistance: suitable for long-term exposure to dynamic loads or harsh environments (such as marine and chemical environments).

|

Product Information |

|

|

Product Type |

12K Multiaxial Carbon Fiber Fabric |

|

Material |

100% carbon fiber |

|

Fabric Type |

0°90° |

|

Width |

127cm |

|

Length |

100cm |

|

Weight |

200-600gsm or customized |

|

Color |

Black |

|

Thickness |

0.25mm-0.6mm |

More Choice

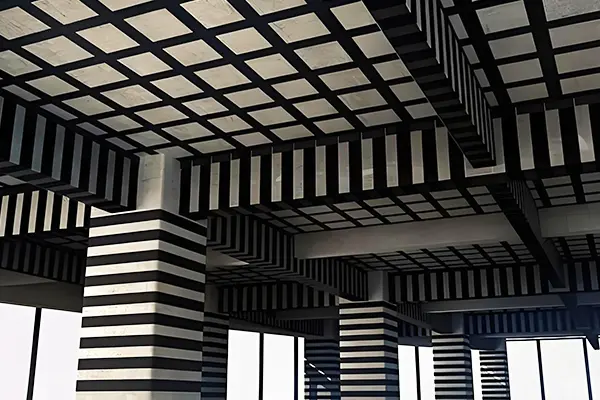

Application Field

Main load-bearing structures of aircraft: wing beams, fuselage keel.

Spacecraft components: satellite truss, rocket fuel storage tank.

●Its advantages are as follow:

Reduce weight by 30%-50%, significantly lowering fuel consumption.

Fatigue resistance: 3-5 times longer than the lifespan of metal materials.

High temperature resistance: Used in combination with high temperature resistant resin(such as polyimide)for engine nacelles.

Blade main beam: In Vestas’120 meter blades, the axial distribution accounts for over 60%, achieving a 20% reduction in blade weight.

Strengthening layer at the root of the blade: resists bending stress under extreme wind loads.

●Industry Trends:

Segmented blade manufacturing: Modular splicing of axial farbic prepreg to reduce transportation costs.

Recycling technolog: Some companies will launch a recyclable resin system to solve the problem of waste blade disposal.

Why Choose Us?

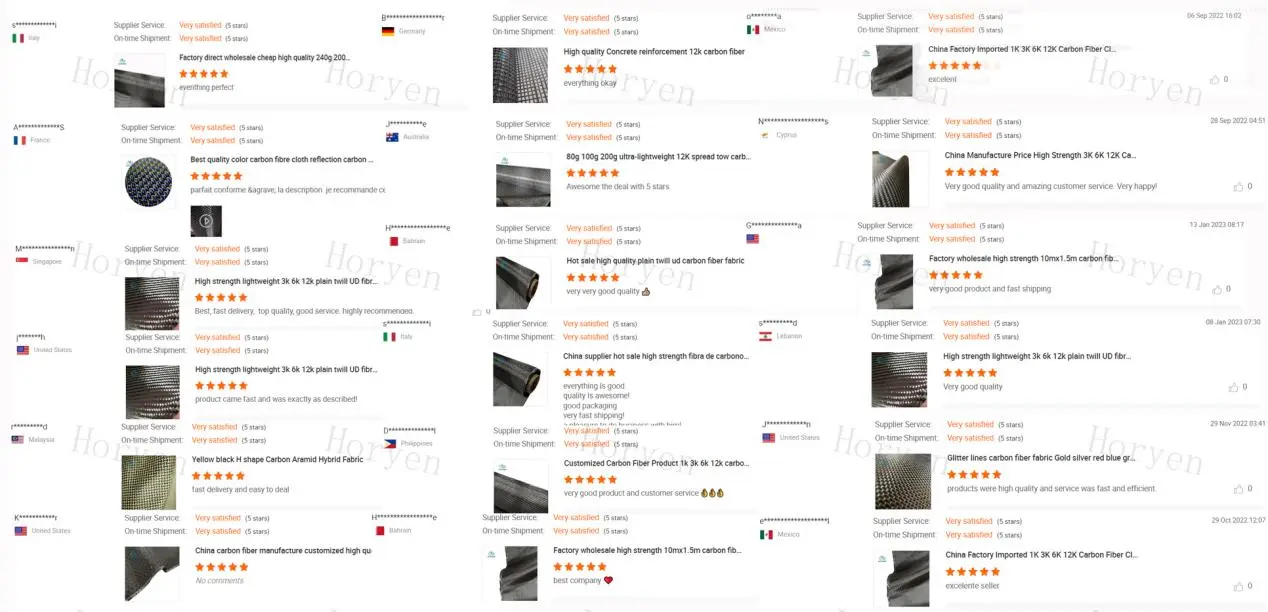

Buyer Review

Our Factory

Packing & Transportation

FAQ

Product Parameter

| Product Information | |||||

| Product Type | 3D Triaxial Spread Tow Fabric | ||||

| Material | 100% carbon fiber | ||||

| Fabric Type | Cloth | ||||

| Warp | Customized | ||||

| FAW | Customized | ||||

| Thickness | Customized | ||||

| Color | Black | ||||

| Width | Customized | ||||