01

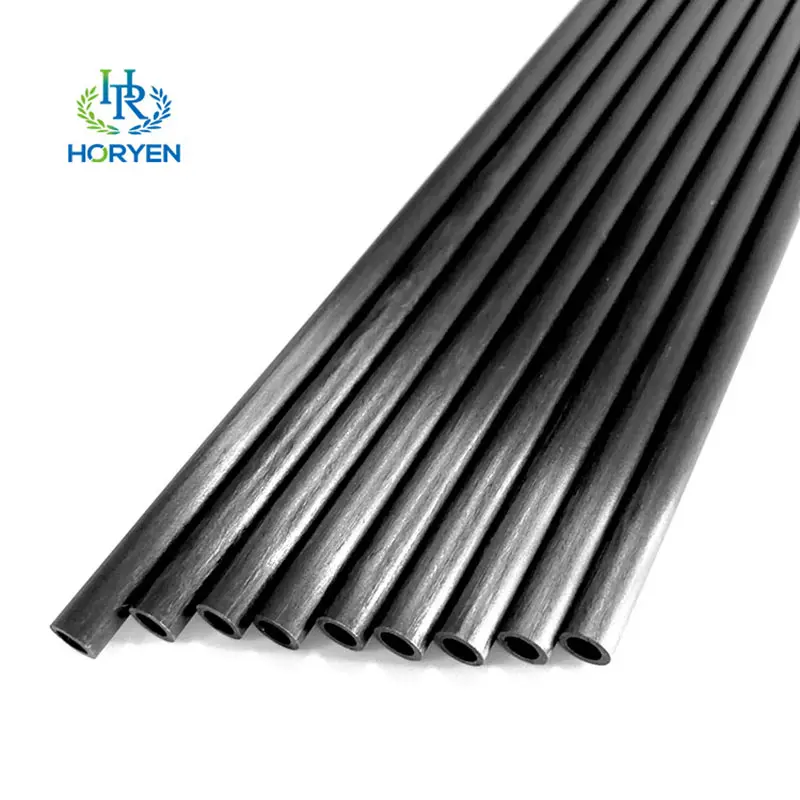

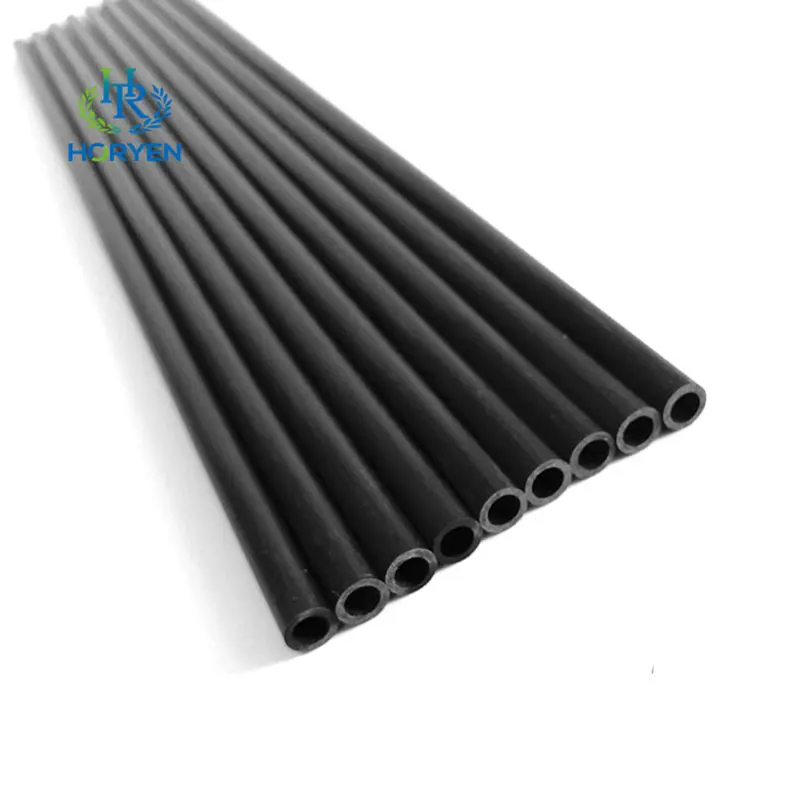

Custom Lightweight Hollow Carbon Fiber Pultrusion Tubing

Product Feature

1. The coefficient of thermal expansion is low, especially in the axial direction dominated by fibers, and the size is less affected by temperature changes, ensuring the stability of exact structures.

2. The mechanical properties exhibit significant anisotropy, with extremely high strength and stiffness along the fiber axis (tube length direction) and relatively low transverse (circumferential and radial), mainly determined by the resin matrix and a small amount of transverse fibers or fabrics (if a circumferential reinforcement layer is added). This characteristic requires special attention in design.

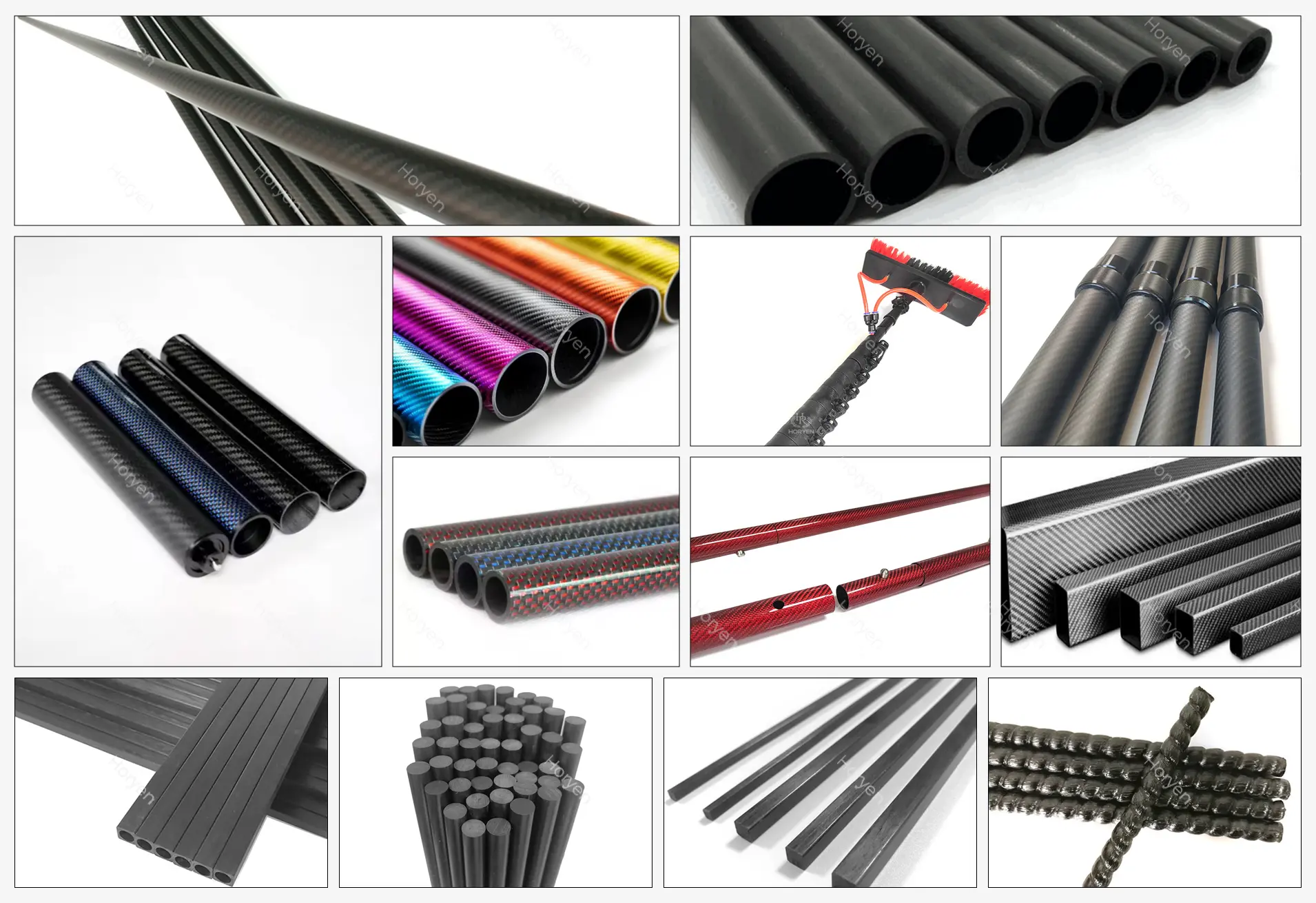

3. Good design flexibility can be achieved by changing the mold shape, fiber type, layer structure (such as adding circumferential or angled fabric layers to the pipe wall to enhance circumferential strength or torsional resistance), resin system, and fiber volume content. The mechanical properties (strength, stiffness, toughness), electrical properties (conductivity or insulation), thermal properties, and appearance of the pipe material can be adjusted within a certain range to meet specific application requirements.

2. The mechanical properties exhibit significant anisotropy, with extremely high strength and stiffness along the fiber axis (tube length direction) and relatively low transverse (circumferential and radial), mainly determined by the resin matrix and a small amount of transverse fibers or fabrics (if a circumferential reinforcement layer is added). This characteristic requires special attention in design.

3. Good design flexibility can be achieved by changing the mold shape, fiber type, layer structure (such as adding circumferential or angled fabric layers to the pipe wall to enhance circumferential strength or torsional resistance), resin system, and fiber volume content. The mechanical properties (strength, stiffness, toughness), electrical properties (conductivity or insulation), thermal properties, and appearance of the pipe material can be adjusted within a certain range to meet specific application requirements.

|

Product Information |

|

|

Product Type |

Pultruded Carbon fiber tube |

|

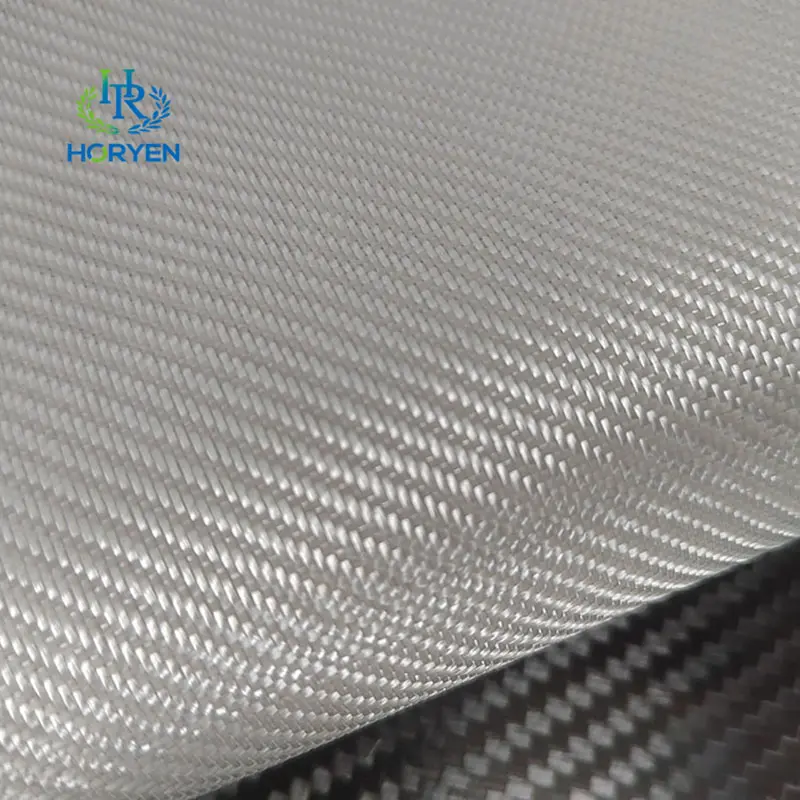

Material |

100% carbon fiber and Epoxy resin |

|

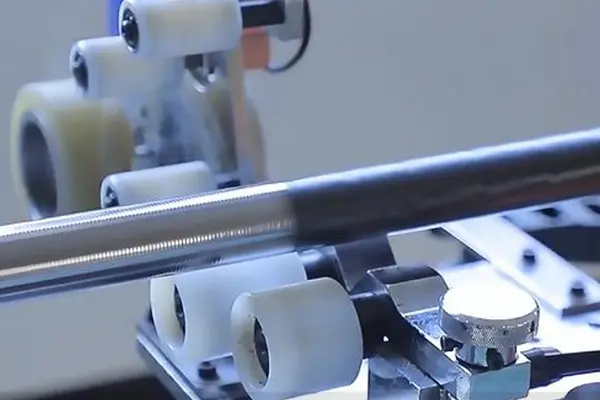

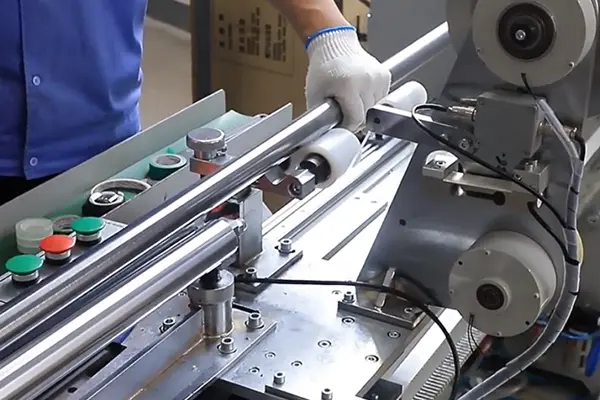

Process |

Pultrusion |

|

Color |

Black |

More Choice

Application Field

The application fields of pultruded carbon fiber tubes are very extensive, with the most prominent being in the automotive and aviation industries. In the automotive industry, pultrusion carbon fiber tube can be used for the manufacturing of components such as body frames, chassis, doors, and wheels. In the aviation industry, extruded carbon fiber can be used for the manufacturing of aircraft fuselage, wings, propellers, engine hoods, and other components.

Why Choose Us?

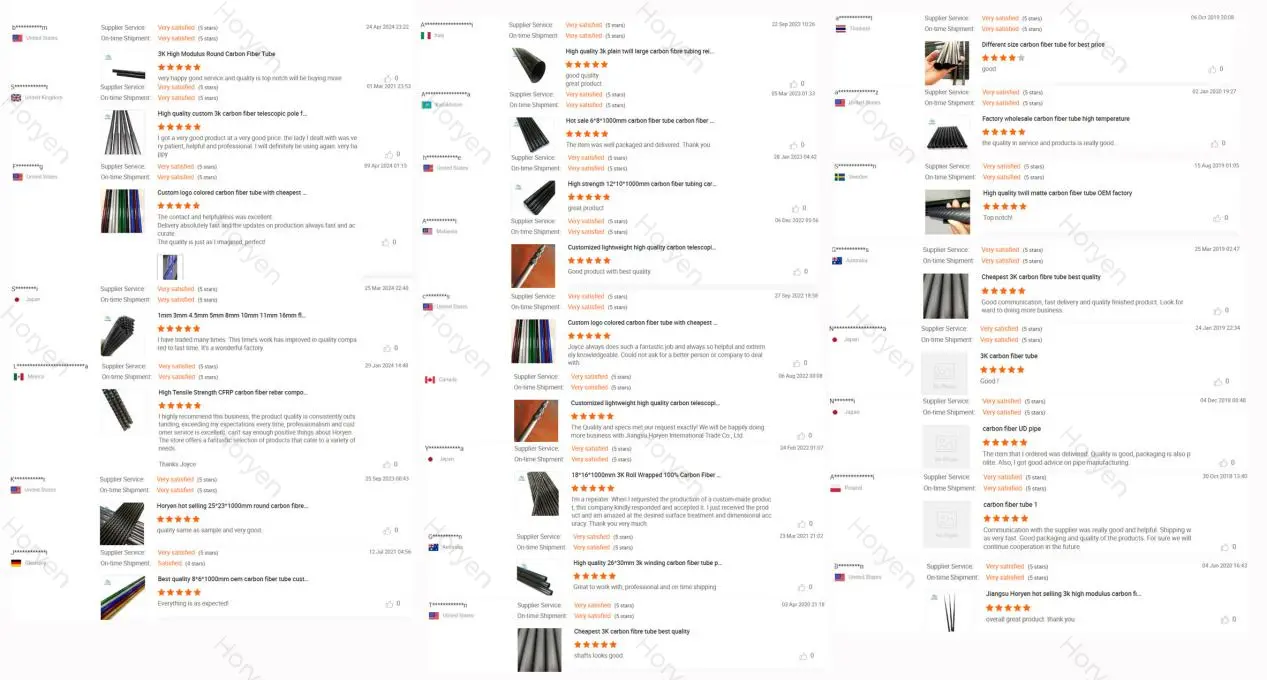

Buyer Review

Our Factory

Packing & Transportation

FAQ

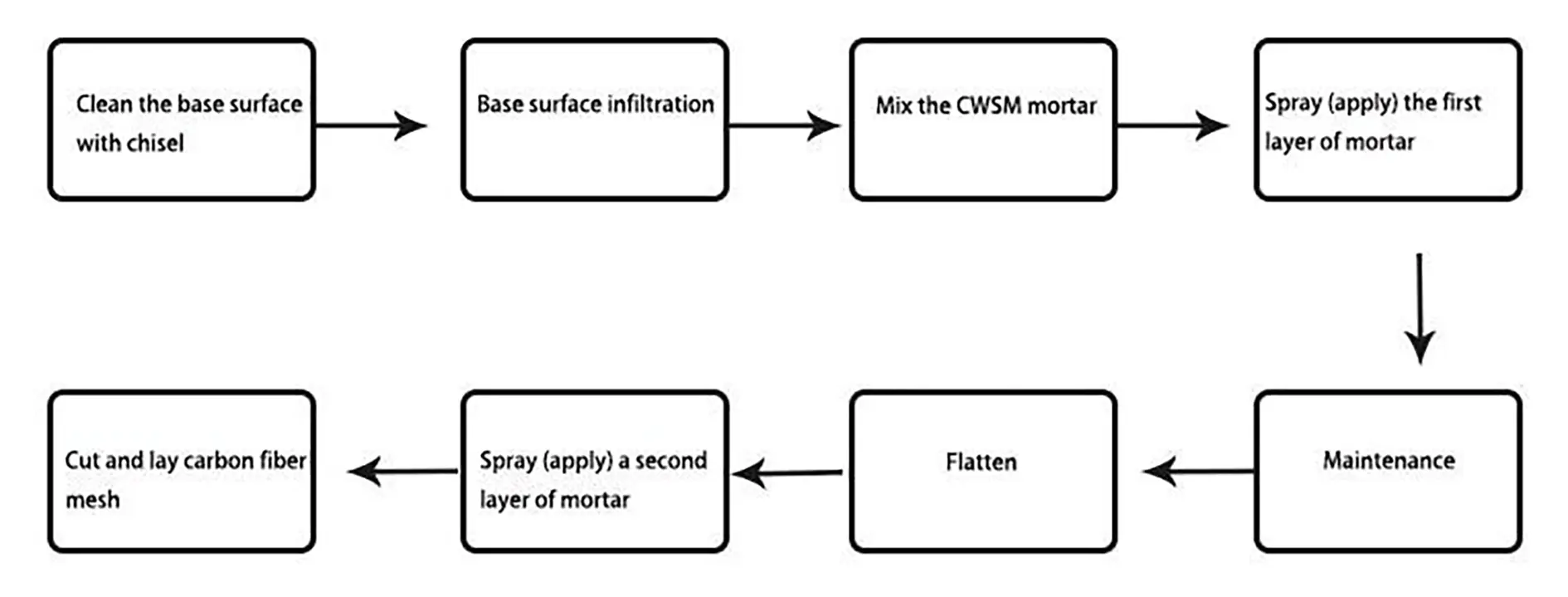

Flow Chart