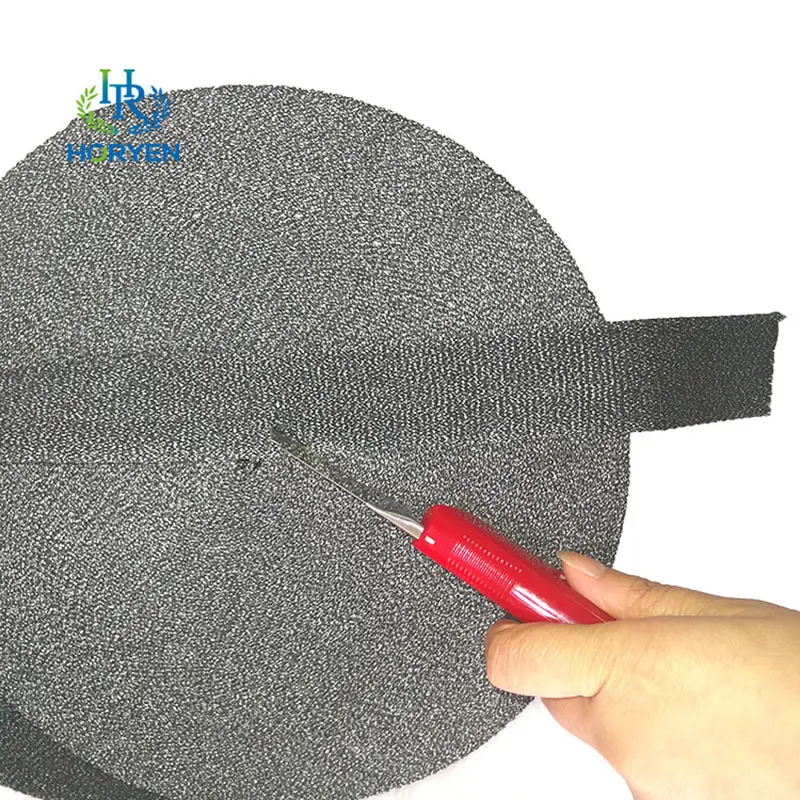

Customized Cut Proof UHMWPE Fiber Webbing

Product Main performance

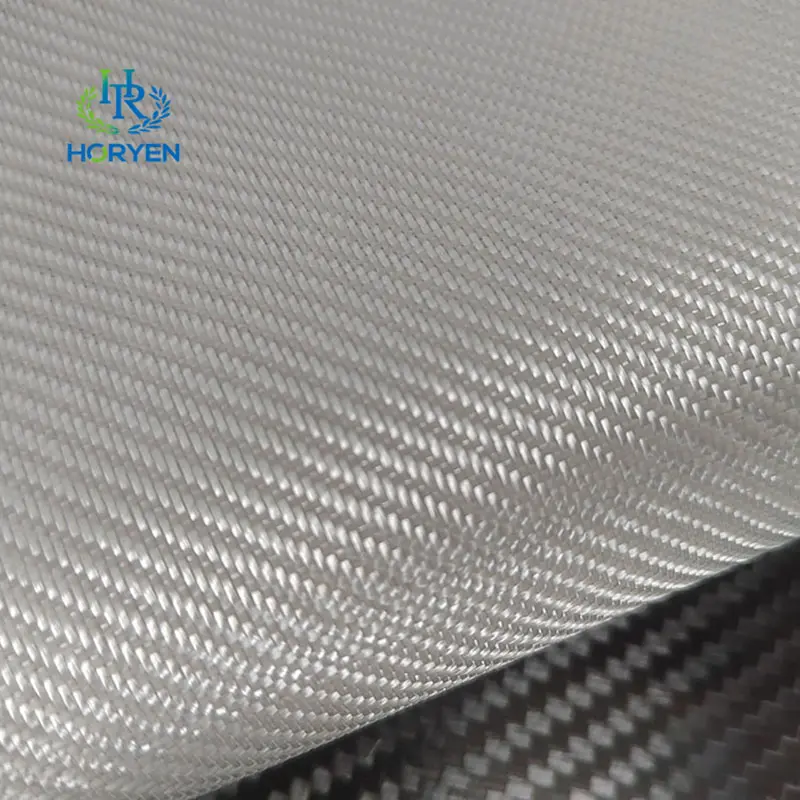

1. Wear resistance: UHMWPE has excellent wear resistance and can withstand long-term rubbing without being easily damaged.

2. High strength and toughness: It has very high tensile strength, good toughness, and can withstand large impact forces without easily breaking.

3. Lightweight: UHMWPE has a lower density, is lightweight, and is easy to carry and use.

4. Excellent flexibility: Anti cutting UHMWPE fiber tape has good flexibility and can adapt to different shapes of objects for protection.

5. Low rubbing coefficient: This material has a low rubbing coefficient, which reduces wear and resistance when in contact with other surfaces.

Working temperature

A wide range of cold heat resistance: with -60 ° C condition, it can keep a certain mechanical strength and heat resistance temperature arrive 80-100 ° C.

Product Parameter

|

Name |

High strength anti-cutting ribbon |

|

Specifications |

220D |

|

Color |

Dark grey |

|

Elastic index |

Inelastic |

|

Intensity index |

2T |

|

Wear resistant index |

High wear resistance |

|

The cut standard |

EN388 |

Application Field

● Cut resistant gloves: UHMWPE fiber webbing is used for manufacturing cut resistant gloves, widely used in manufacturing, construction, logistics, and express delivery industries to protect workers' safety during operation.

● Anti cutting clothing: UHMWPE fiber webbing is used in certain high-risk industries such as aviation, automotive manufacturing, glass processing, etc., to provide additional protection for operators.

● Protective belts and equipment: UHMWPE fiber webbing is used to make work protective belts, protective gear, etc., to enhance the safety of workers.

Why Choose Us?

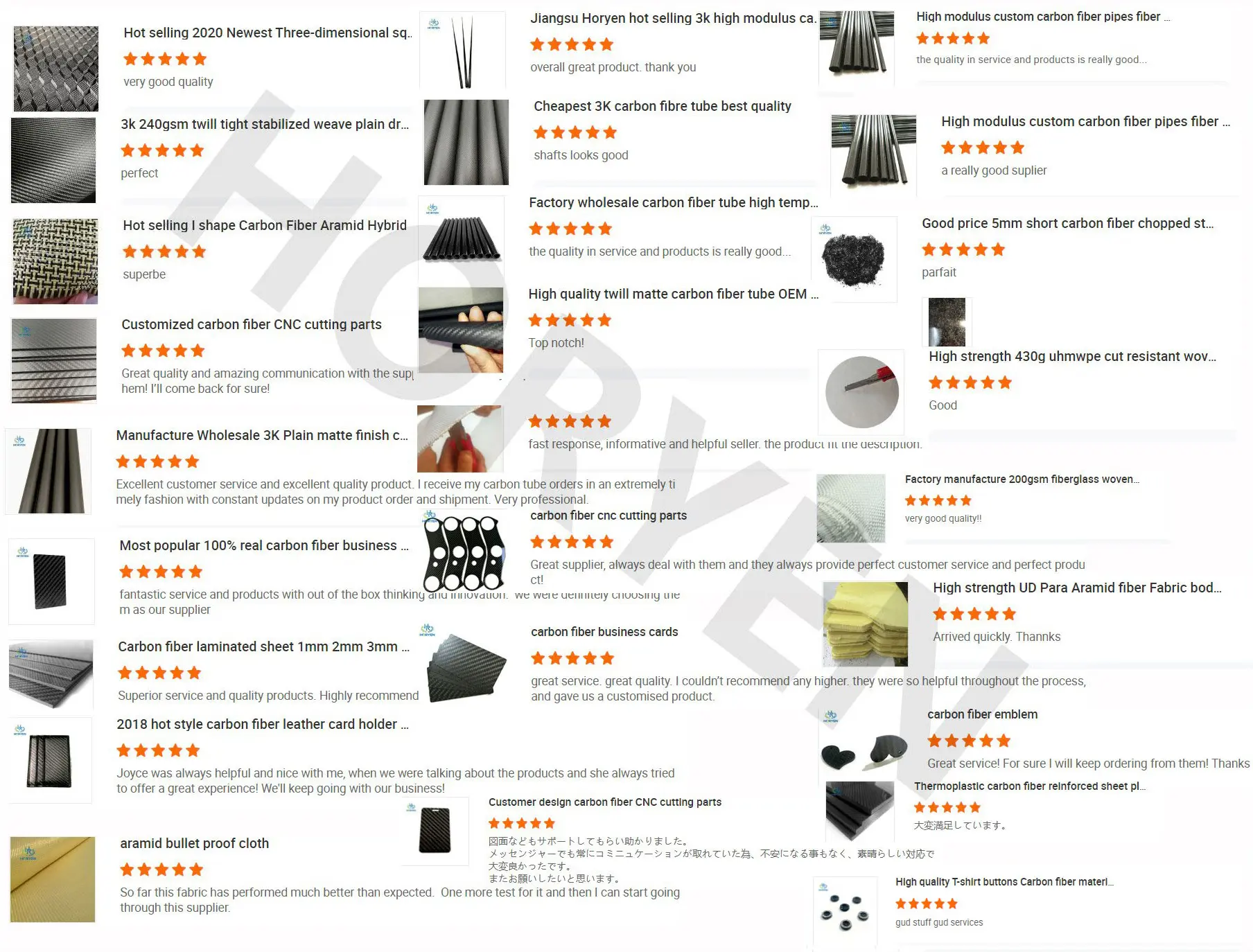

Buyer Review

Our Factory

Packing & Transportation

FAQ

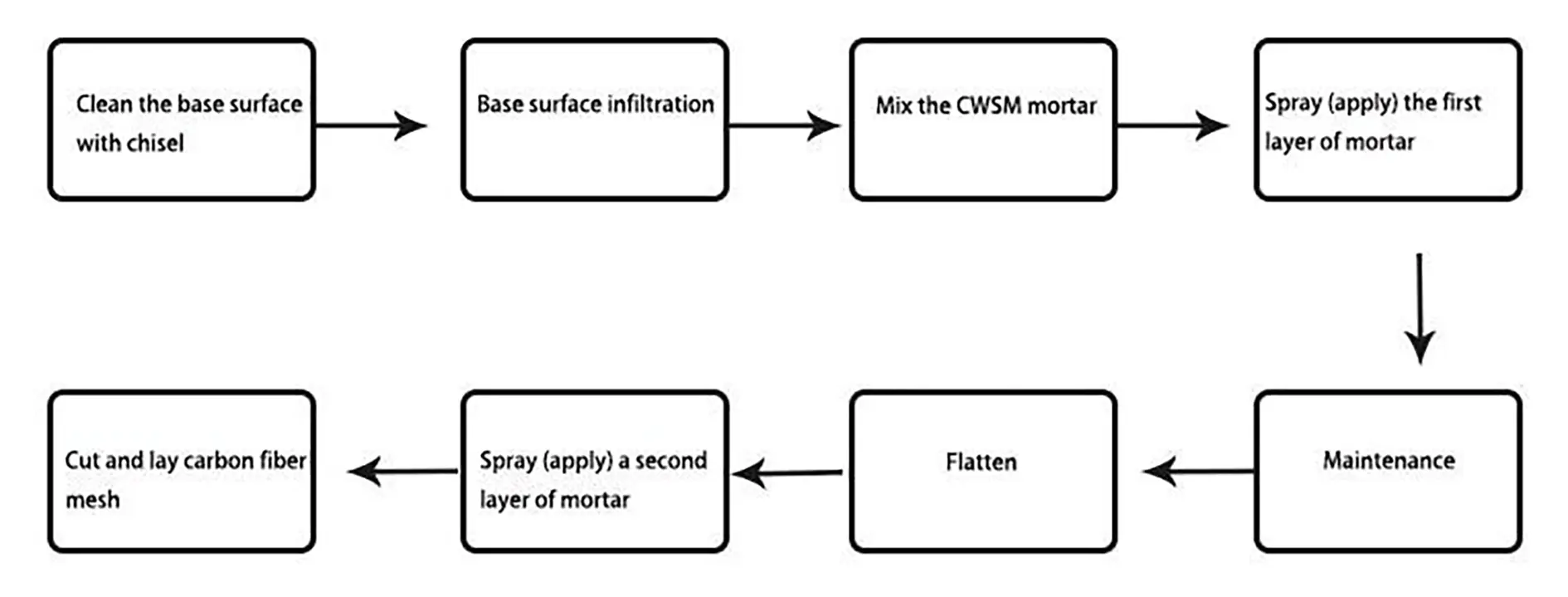

Flow Chart