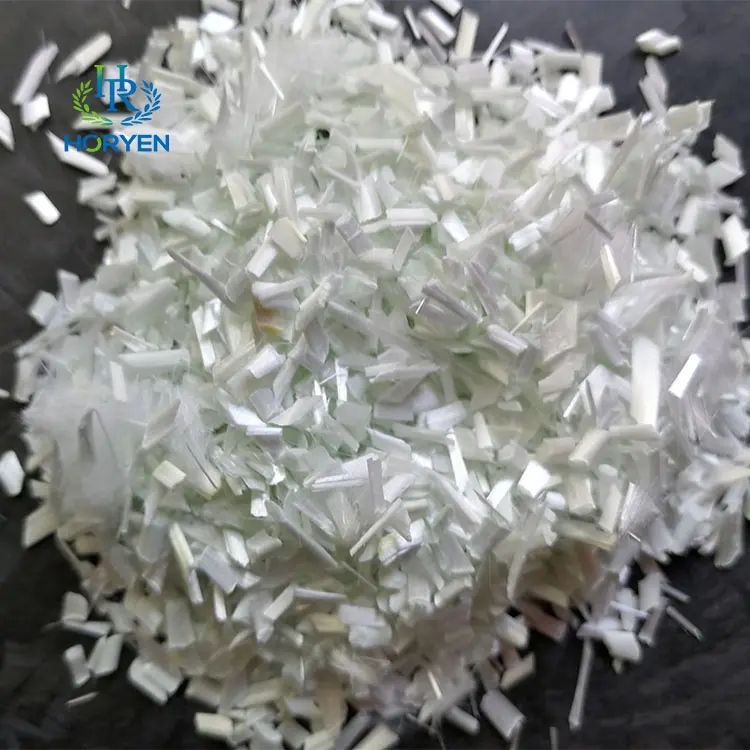

Customized Length Reinforced Concrete Glass Fiber Chopped Strands

Product Features

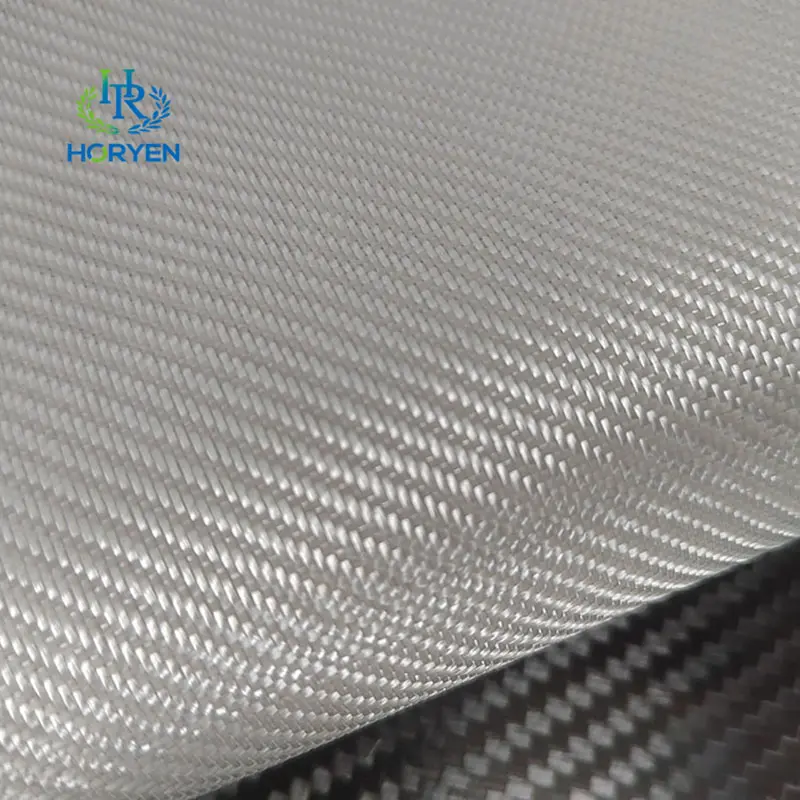

In the application process, short cut fibers are uniformly incorporated into the matrix material (such as thermosetting resins such as unsaturated polyester, epoxy resin, vinyl resin, or thermoplastic resins such as polypropylene, nylon, polycarbonate, etc.) as reinforcing phases. When composite materials are subjected to load, these randomly distributed short cut wires can effectively bear stress, significantly improving the mechanical strength (including tensile strength, bending strength, impact toughness), rigidity, dimensional stability, heat resistance, and fatigue resistance of the final product. Its "short cut" shape gives it a unique processing advantage: compared to continuous fibers, short cut fibers have better flowability when mixed and are easier to achieve uniform dispersion (reducing clumping) in the matrix, making it very suitable for efficient and complex molding processes such as molding, injection molding, premix, wet sampling, etc., especially for manufacturing components with complex shapes and high dimensional accuracy requirements.

Product Parameter

|

Style number |

ECS-3.0 |

ECS-4.5 |

ECS-6.0 |

|

Glass type |

E-glass |

E-glass |

E-glass |

|

Glass fiber style |

GRC or BMC |

GRC or BMC |

GRC or BMC |

|

Filament diameter(m) |

11±1 |

11±1 |

11±1 |

|

ECS length (mm) |

3 |

4.5 |

6 |

|

Moisture(%) |

≤0.3 |

≤0.3 |

≤0.3 |

|

Combustible matter(%) |

1 ±0.20 |

1 ±0.20 |

1 ±0.20 |

|

Choppability(%) |

≥98 |

≥98 |

≥98 |

|

R2O(%) |

≤0.8 |

≤0.8 |

≤0.8 |

Application Field

Glass fiber chopped strand is a key raw material for manufacturing automotive components (bumpers, dashboard brackets, engine hood components), electronic and electrical components (connectors, switches, housings), building materials (roof panels, sanitary ware, water tanks), sports equipment, pipeline fittings, rubbing sealing materials (brake pads, clutch pads), as well as various industrial containers and consumer goods.

Its length and diameter (usually in the range of 5-20 microns per filament) can be precisely selected and customized according to the performance requirements and processing technology of the final product, making it an essential core reinforcement material for balancing material performance, processing efficiency, and cost-effectiveness.

Why Choose Us?

Buyer Review

Our Factory

Packing & Transportation

FAQ

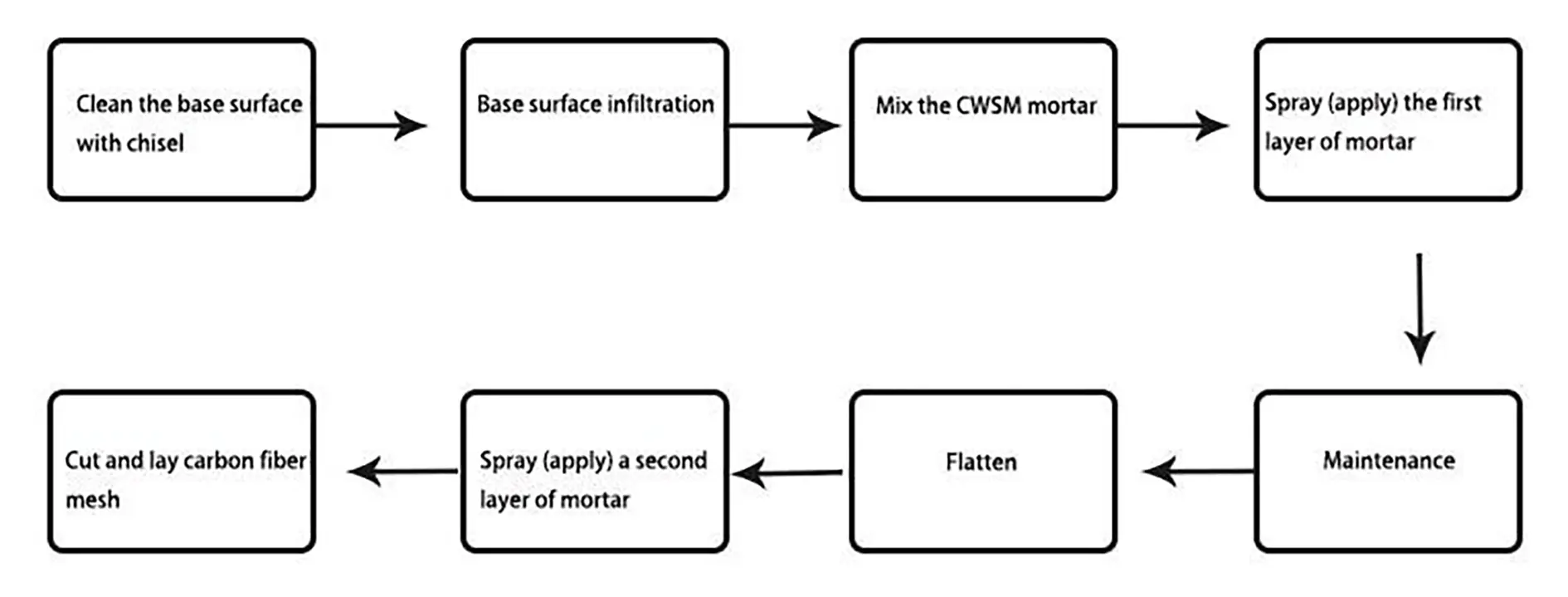

Flow Chart