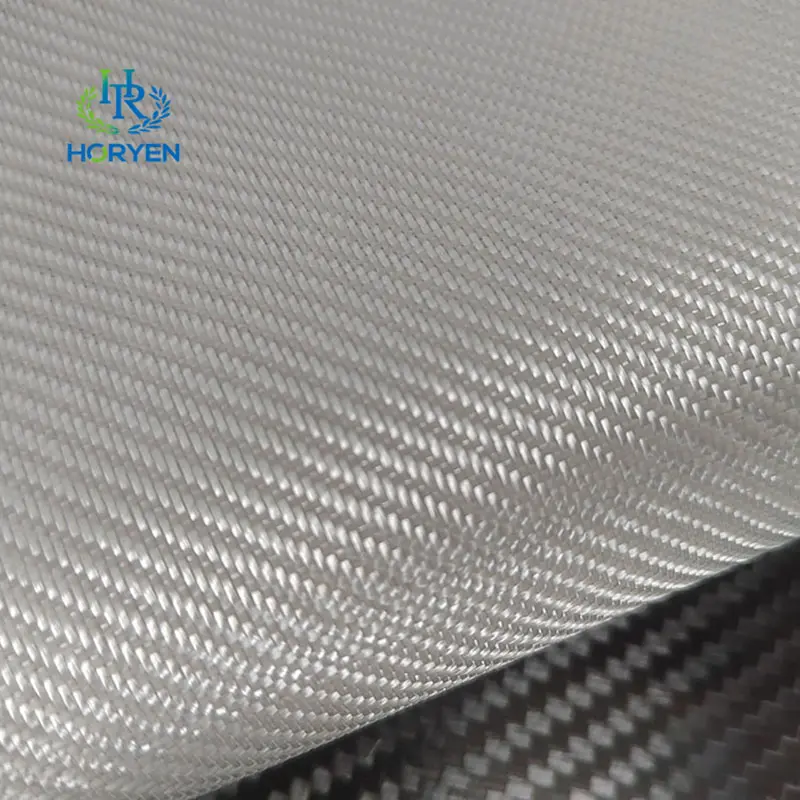

Fire Resistant 3A Aramid Fiber Fabric For Workwear

Product Advantage

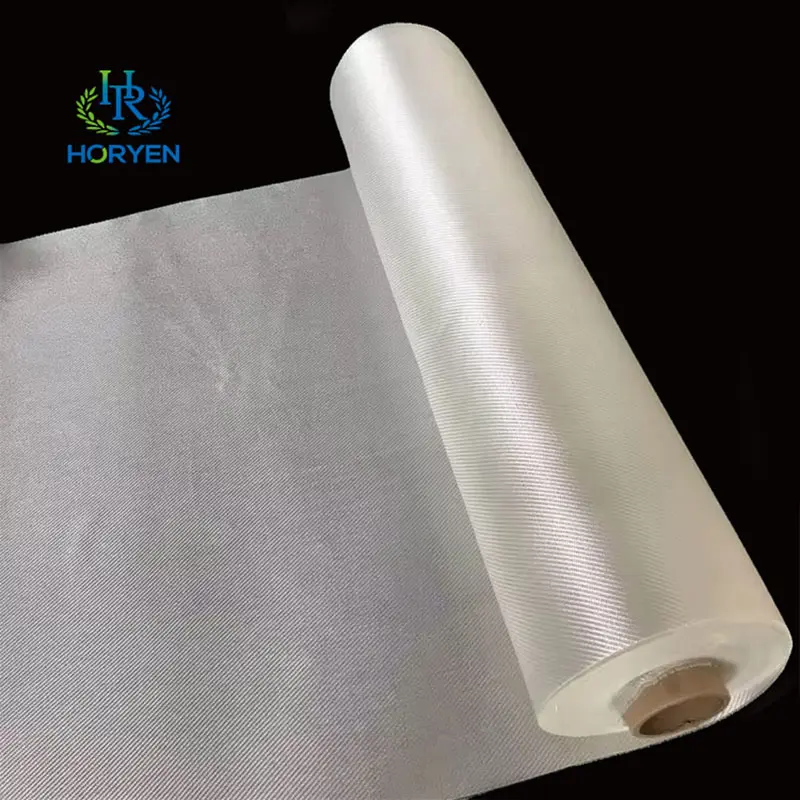

Aramid IIIA fabric: Made of a new generation of high-tech fibers, Aramid 1313/Aramid 1414/conductive fibers, blended in a 93%/5%/2% ratio, it has high strength, tear resistance, wear resistance, and excellent high-temperature resistance, flame retardancy, and fire resistance. This fabric is widely used for special protective clothing for personnel in fields such as fire protection, metallurgy, aerospace, and aviation.

Product Feacture

1. Has permanent flame resistance, high temperature resistance, and will not melt, burn, or melt droplets.

2. Acid and alkali resistance, corrosion resistance, high strength, friction resistance, and long service life (6 times that of ordinary flame retardant cotton).

3. Adding carbon fiber has an anti-static effect; Various colors can be customized, with high color fastness.

4. Stable size, no deformation due to water washing.

5. Good breathability, light weight, and comfort.

Product Parameter

|

Name |

Aramid fabric |

|

Material |

93% Meta aramid fiber (1313) + 5% aramid fiber (1414) +2% conductive fiber |

|

Width |

58/60" or customized |

|

Weave/warp |

Twill |

|

FAW |

150-240 gsm |

|

Shrinkage |

±3% |

|

Service |

OEM/ODM |

Application Field

Due to its high temperature resistance, it can maintain stable performance in high-temperature environments and is suitable for situations that require high temperature resistance. For example, industrial flame-retardant workwear.

The lightweight and high-strength properties of aramid fabric provide excellent protective effects. It is commonly used to make protective equipment such as elbow pads, knee pads, protective headgear, and insulated gloves.

Why Choose Us?

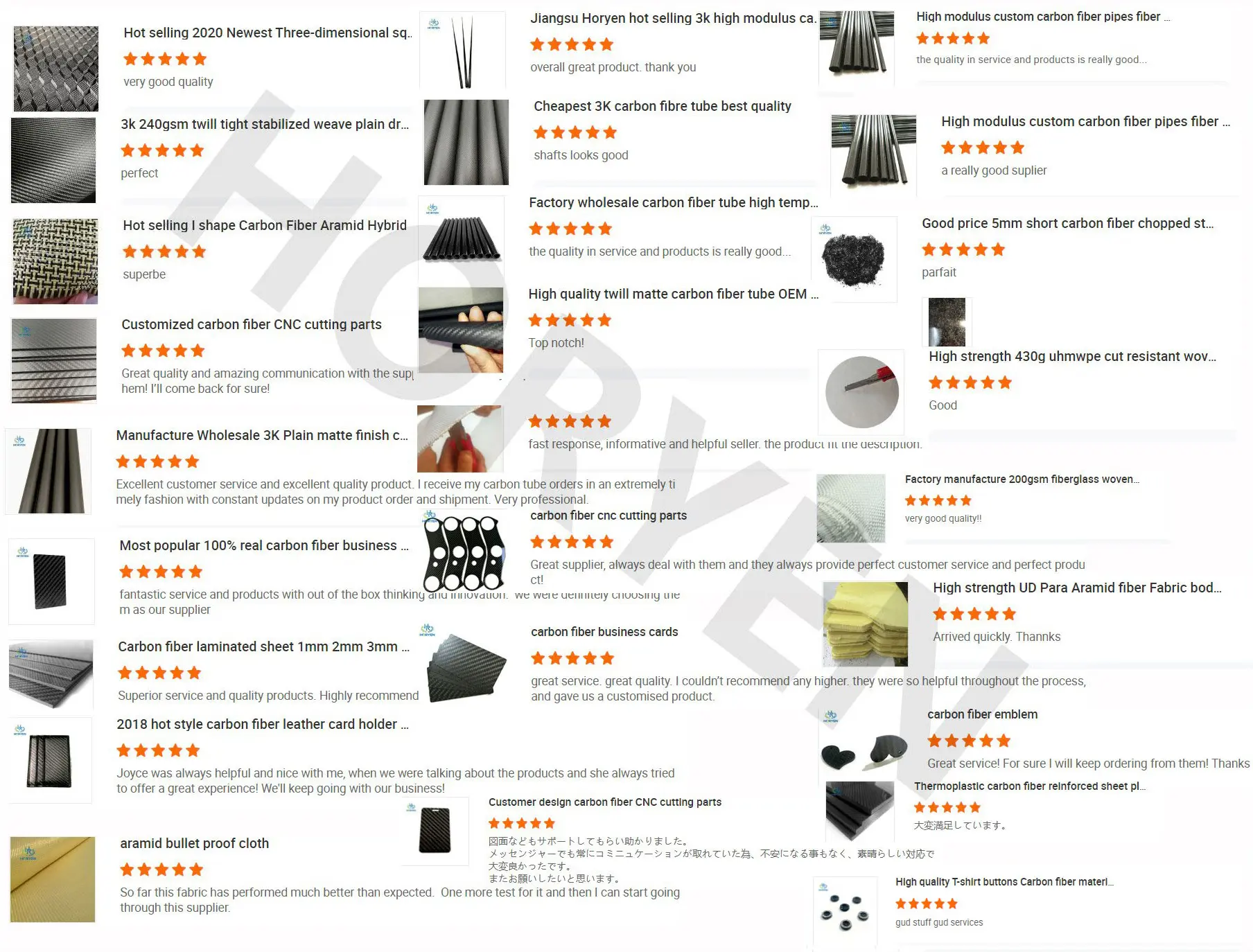

Buyer Review

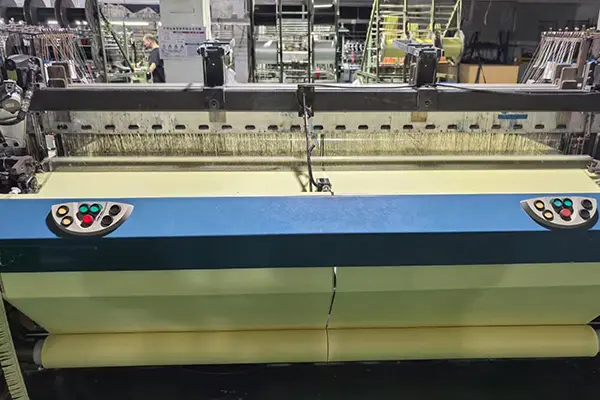

Our Factory

Packing & Transportation

FAQ

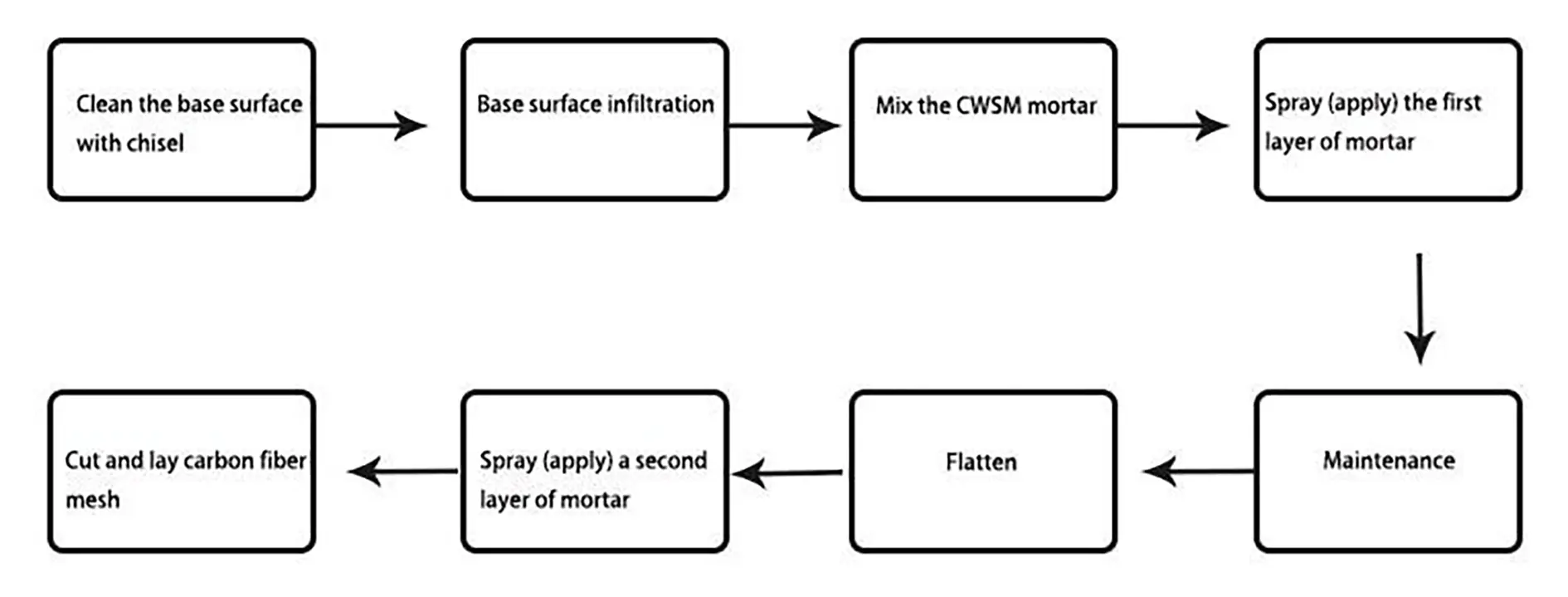

Flow Chart