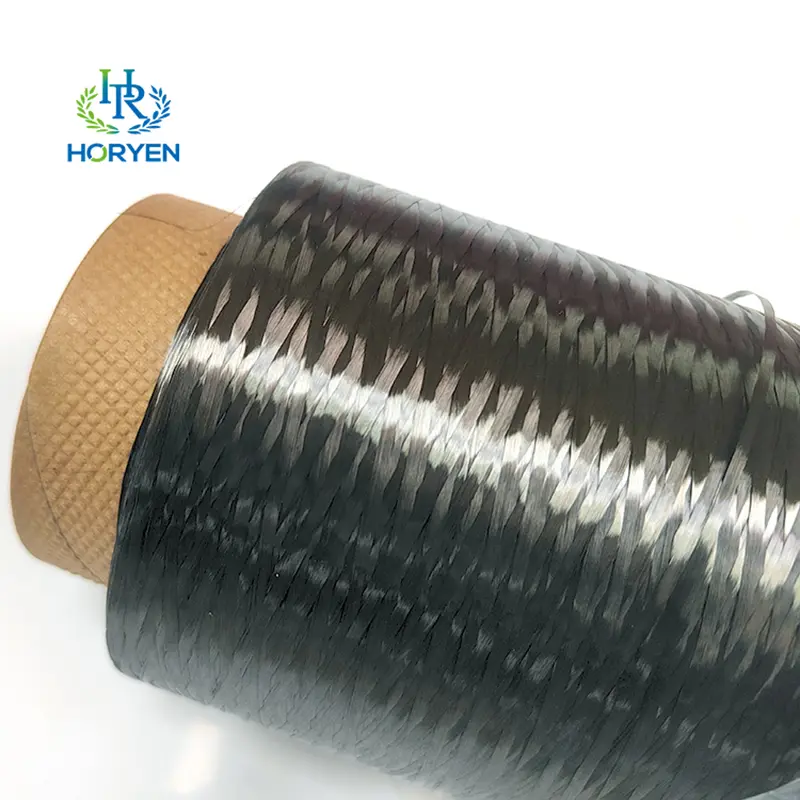

High Modulus 12k 24k Carbon Fiber Rowing Yarn

Product Parameter

|

Product name |

Carbon fiber filament yarn |

|

Product Type |

Carbon fiber |

|

Pattern |

Raw |

|

Feature |

Flame Retardant,Chemical-Resistant,Lightweight, Anti-UV, etc. |

|

Use |

Fabric |

|

Carbon fiber |

|

|

Continuous fiber |

|

|

1K 3K 6K 12K 24K 48K |

|

|

Colour |

Black |

|

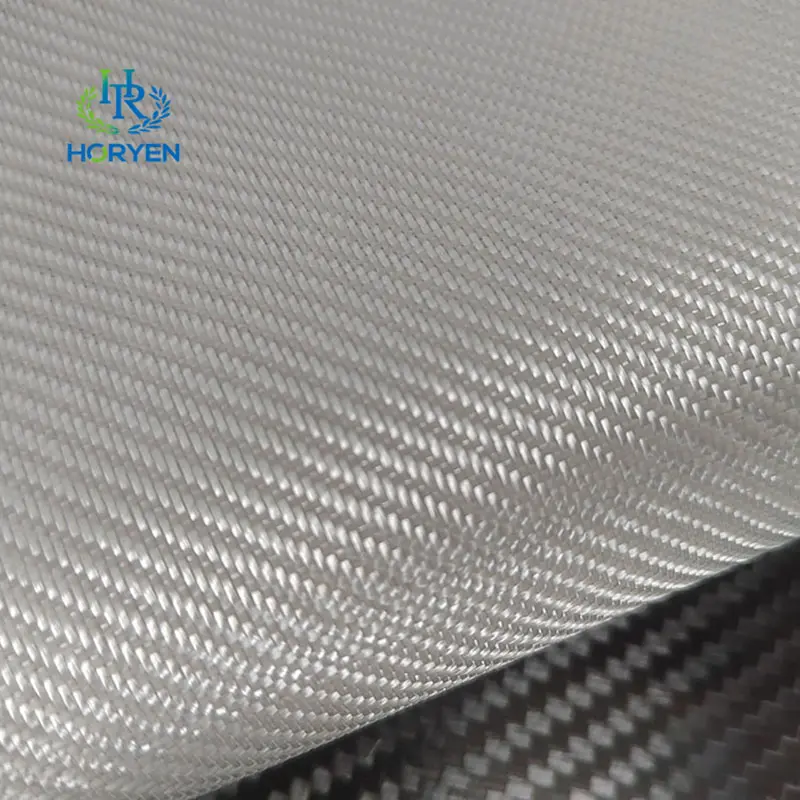

Application |

Carbon fiber fabric |

|

Size |

4KG/roll |

Product Feature

Product Advantage

● Excellent fatigue resistance: Under repeated loading, its performance degradation is much smaller than that of metal materials, with a longer service life and higher safety margin, especially suitable for components that withstand alternating stress (such as aircraft wings and wind turbines blades).

● Good chemical corrosion resistance: It has extremely strong resistance to corrosive media such as acids, alkalis, and salts (except for strong oxidants), far superior to metals, making it perform well in harsh environments such as chemical and marine industries.

● Conductivity: Carbon fiber itself is a good conductor, and this characteristic is applied to anti-static, electromagnetic shielding (such as electronic product casings), or functional composite materials that require electrical heating (such as aircraft de icing).

● Low thermal expansion coefficient: In a specific direction (along the fiber axis), its thermal expansion coefficient is close to zero or even negative, providing excellent thermal dimensional stability.

Application Field

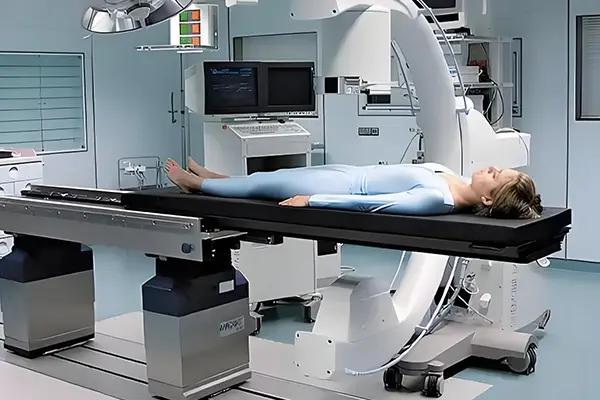

Aerospace field: This is the earliest and most demanding application field. Carbon fiber composite materials are used to manufacture the main load-bearing structures (wings, fuselage, tail wing), cabin walls, landing gear doors, engine compartments, helicopter rotors, etc. of aircraft, significantly reducing weight (reducing fuel consumption, increasing range/load), improving structural efficiency and fatigue resistance. On satellites, rockets, and spacecraft, it is used for structural components, solar panel supports, antenna reflectors, etc., utilizing its lightweight, high strength, high stiffness, and space environment stability.

Why Choose Us?

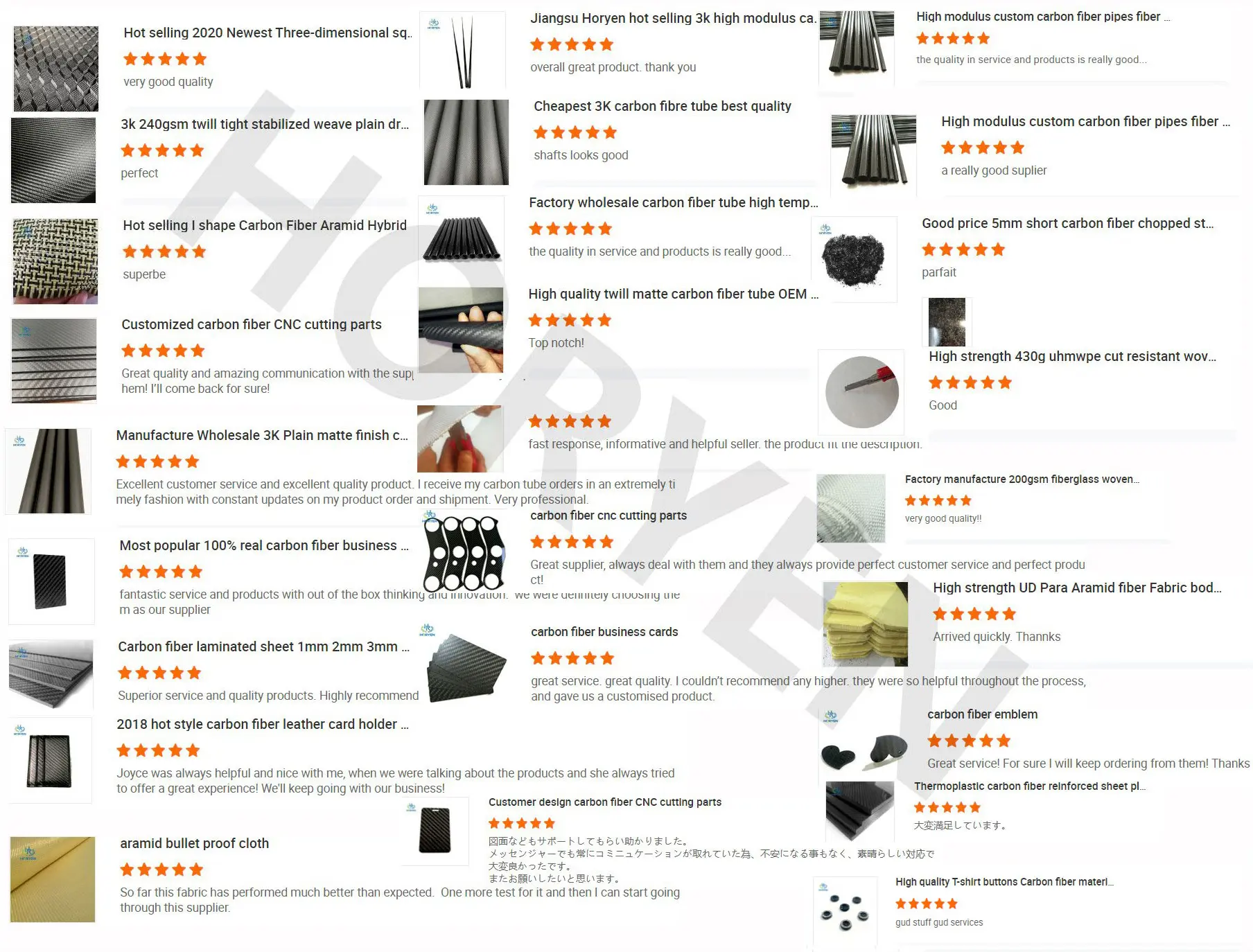

Buyer Review

Our Factory

Packing & Transportation

FAQ

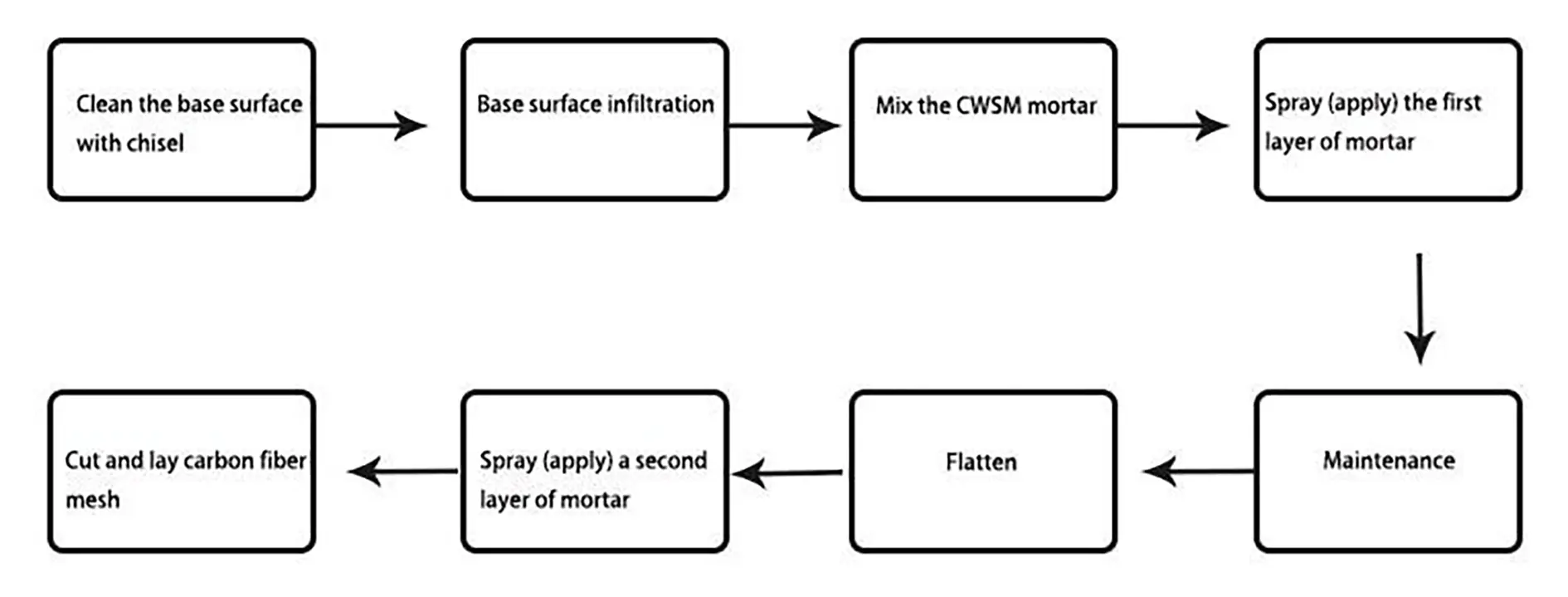

Flow Chart