High Modulus Carbon Fiber Rebar For Reinforcement

Product Feature

1. Lightweight and high-strength: The density of carbon fiber reinforced rebar is only one fourth of traditional steel, but its tensile strength is much higher than ordinary steel, which can withstand greater loads.

2. Corrosion resistance: Carbon fiber reinforced rebar is not easily corroded by chemicals such as acid and alkali, and is suitable for buildings in harsh environments.

3. Low thermal conductivity: Compared with steel, carbon fiber reinforced rebar has weaker thermal conductivity and can effectively reduce the stress caused by temperature changes in the structure.

4. Fatigue resistance: Its excellent fatigue strength ensures that the performance of carbon fiber reinforced rebar remains stable even under long-term stress.

5. Easy to process: Carbon fiber reinforced rebar can be flexibly designed according to needs, making it easy to construct.

|

Product Information |

|

|

Product Type |

Carbon fiber rebar |

|

Material |

100% carbon fiber and epoxy resin |

|

Diameter (mm) |

4~26 |

|

Density (g/cm3) |

1.6~1.8 |

|

Tensile Strength (MPa) |

1800~2200 |

|

E-modulus (GPa) |

140~150 |

|

Elongation (%) |

1.3~1.5 |

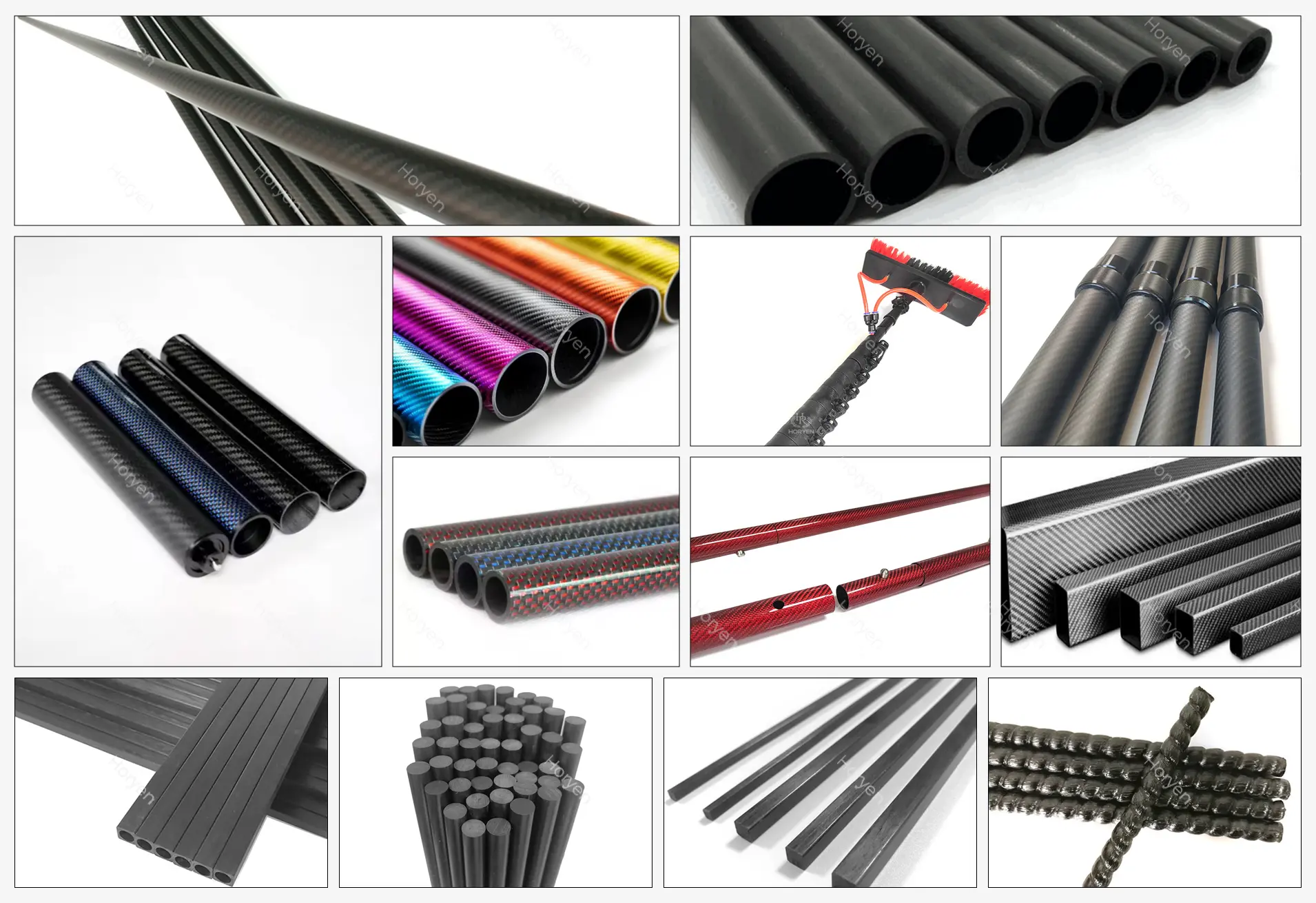

More Choice

Application Field

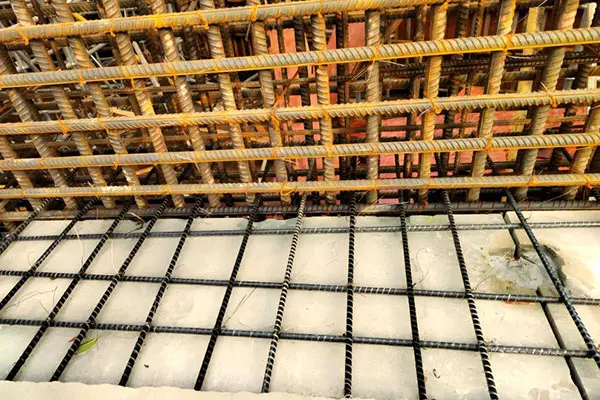

● Civil engineering: can be used for the construction of infrastructure such as bridges, tunnels, roads, subways, etc., to improve the durability and safety of structures.

● Construction industry: particularly suitable for building structures that require weight reduction, such as high-rise buildings, sports arenas, museums, etc.

● Aerospace: Due to its lightweight and high-strength characteristics, carbon fiber reinforced rebar is widely used in the manufacturing of aerospace equipment.

● Marine engineering: suitable for marine platforms, coastal protection and other projects to resist the erosion of seawater.

● Highways and railways can improve the strength and durability of road surfaces, reducing maintenance costs.

Why Choose Us?

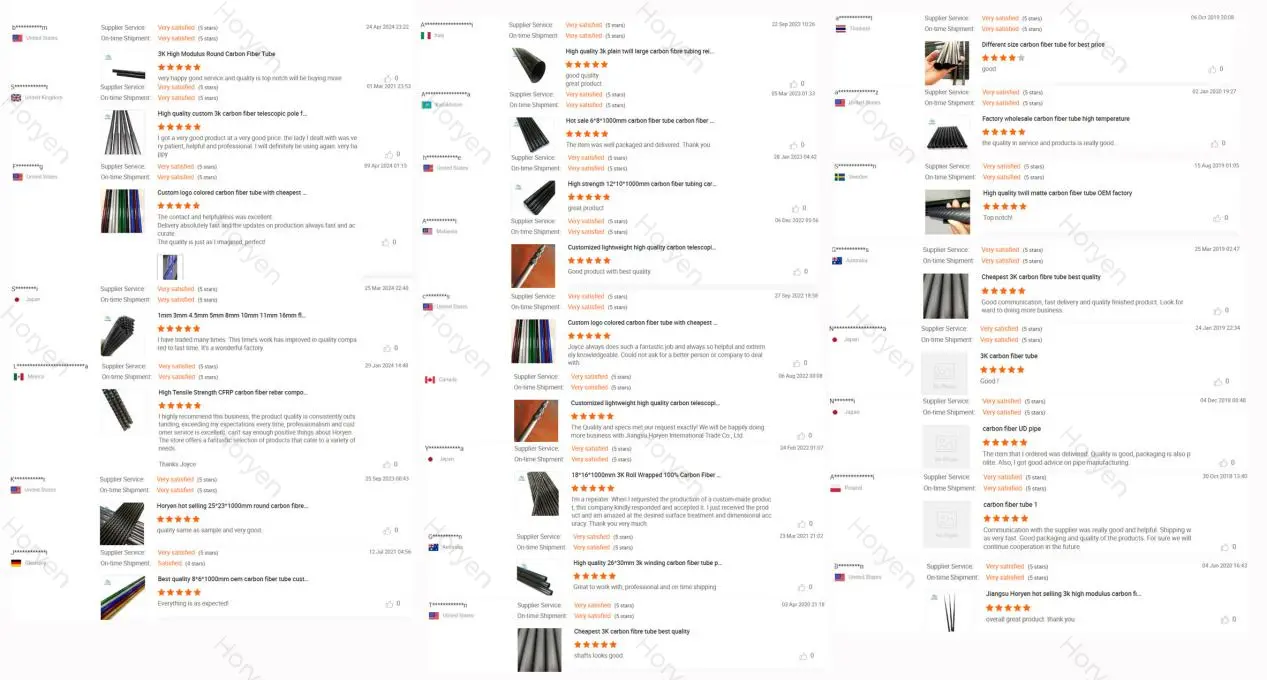

Buyer Review

Our Factory

Packing & Transportation

FAQ

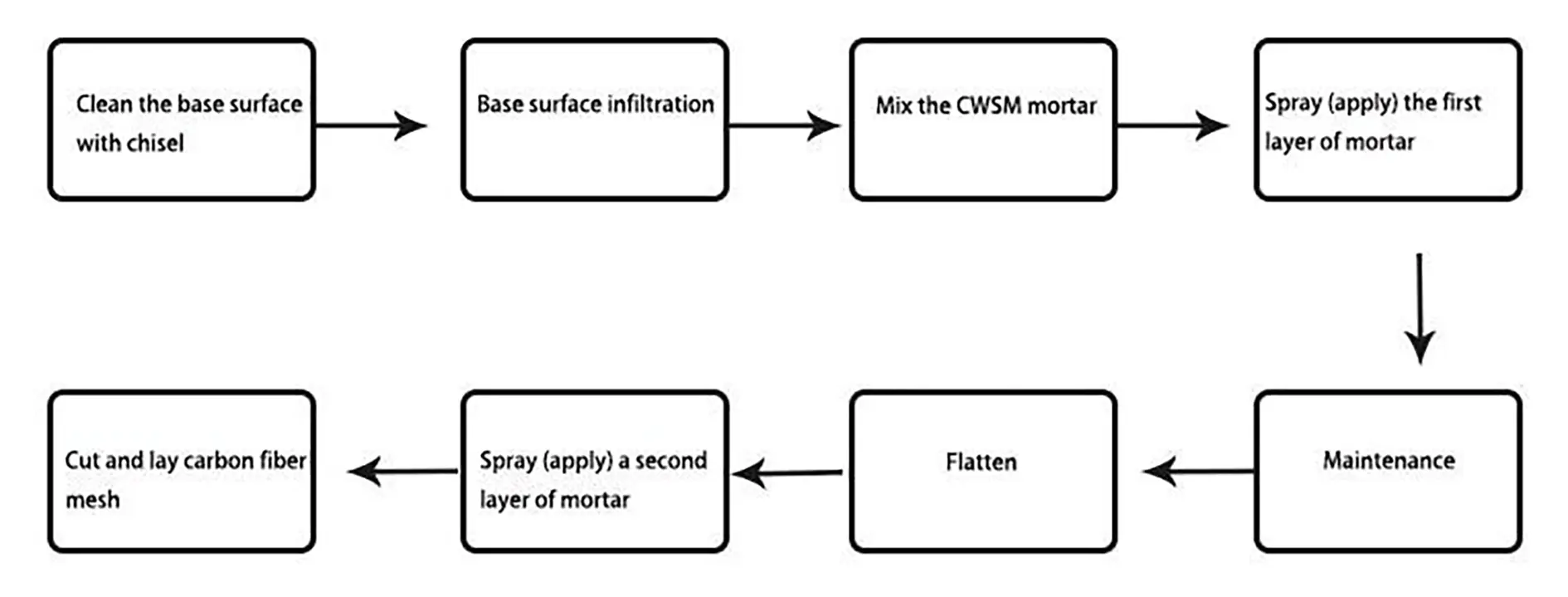

Flow Chart