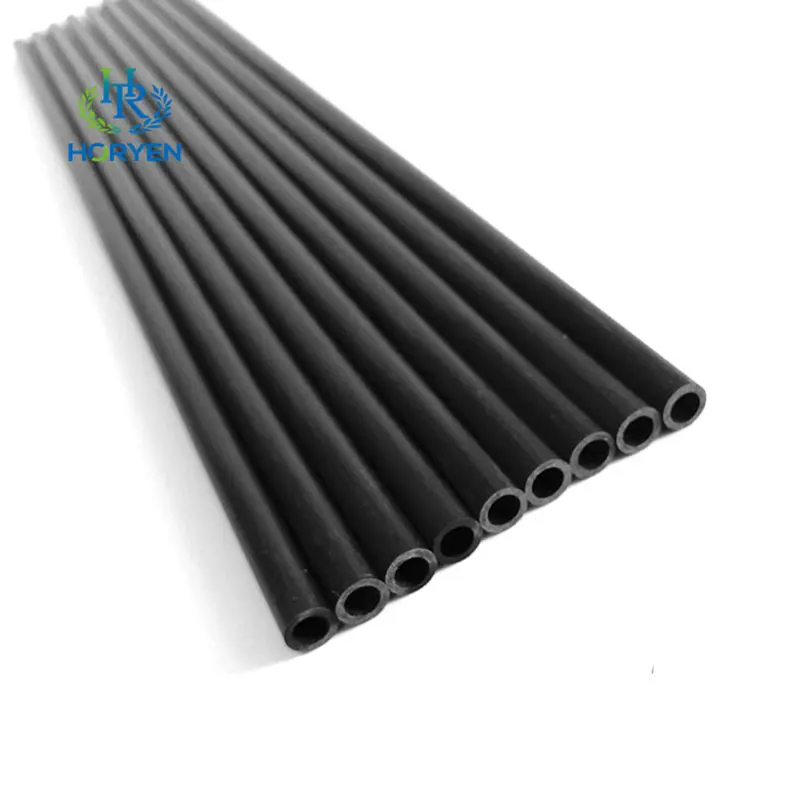

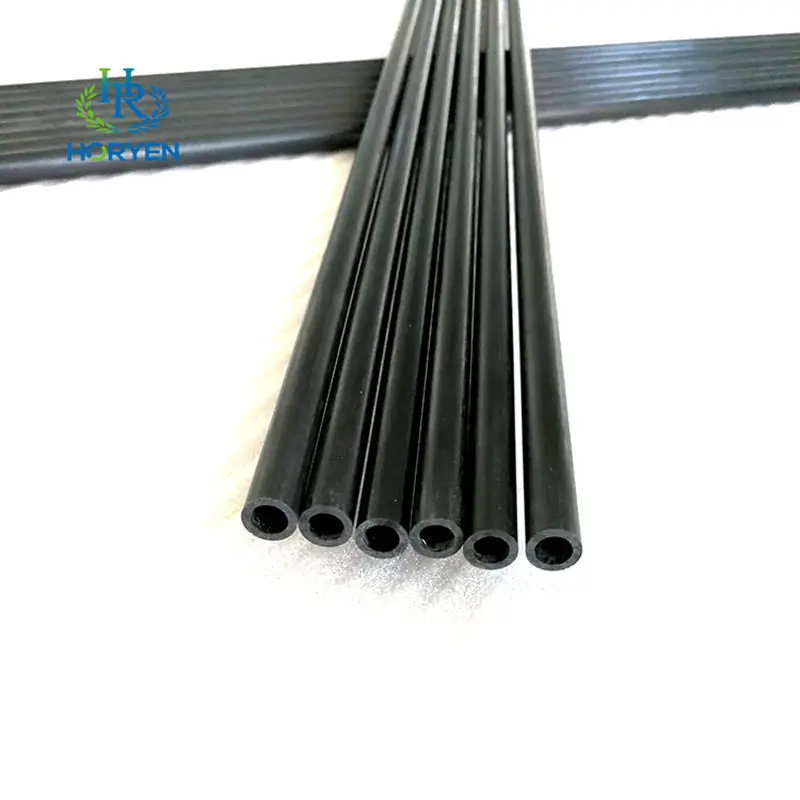

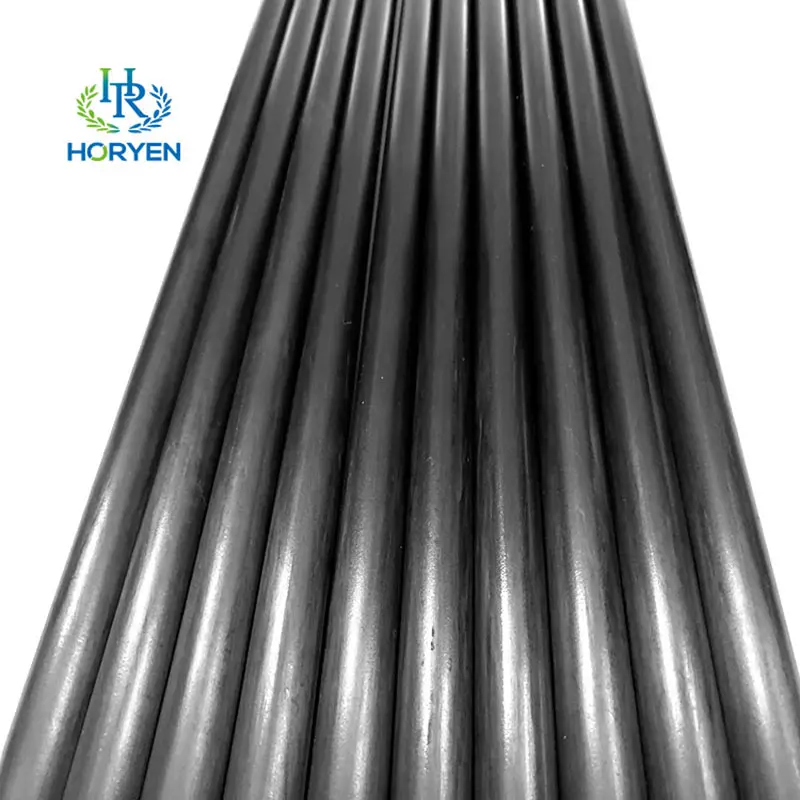

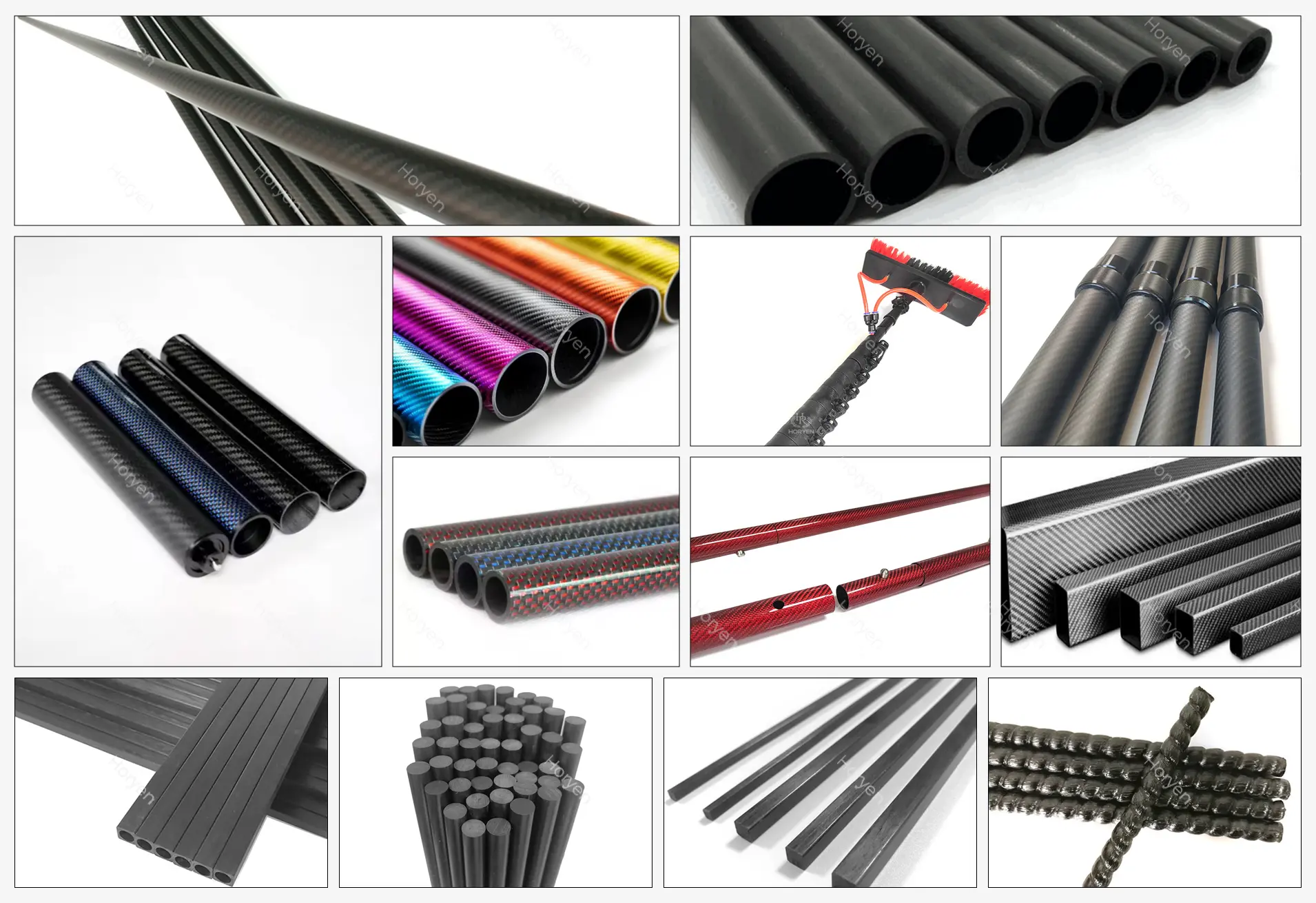

High Quality Round Pultruded Carbon Fiber Tubing

Product Feature

Excellent specific strength (strength to weight ratio) and specific modulus (stiffness to weight ratio) are determined by the ultra-high strength and high modulus characteristics of carbon fiber itself, combined with the high fiber orientation achieved by the pultrusion process (fibers arranged highly parallel along the tube axis, usually with a content of 60% -70% or even higher) and the low porosity matrix. The result is that the pipe material has an astonishing load-bearing ability in the axial direction (length direction) that is close to the theoretical value of carbon fiber, while the overall density is much lower than that of metal materials (such as steel or aluminum), achieving significant lightweight effects. This is important for applications that require weight reduction to improve efficiency, speed, or endurance.

|

Product Information |

|

|

Product Type |

Pultruded Carbon fiber tube |

|

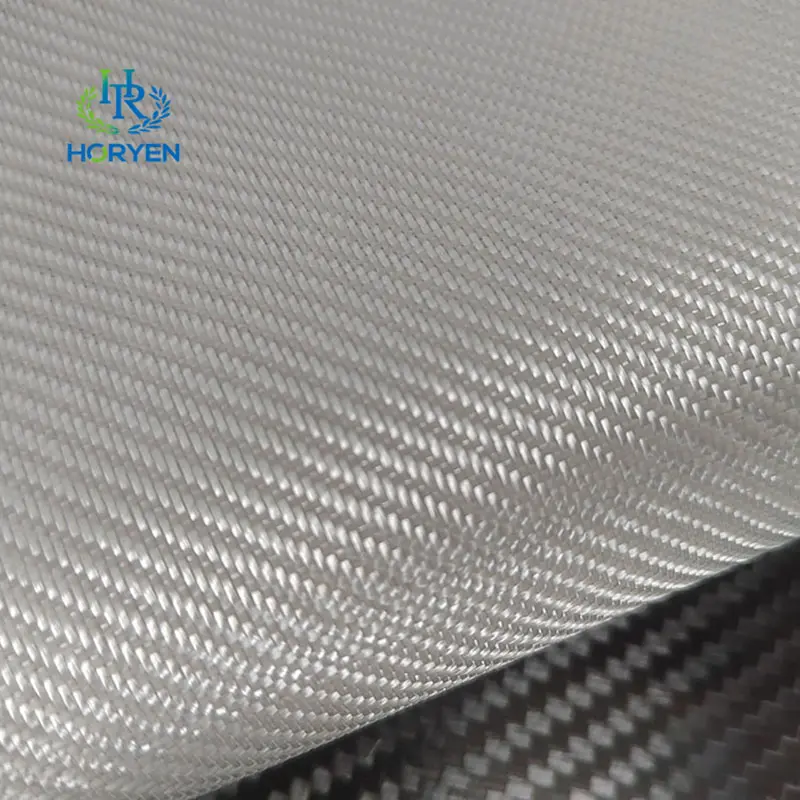

Material |

100% carbon fiber and Epoxy resin |

|

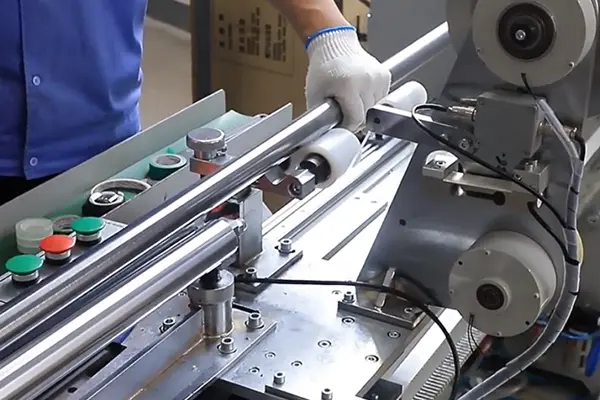

Process |

Pultrusion |

|

Color |

Black |

More Choice

Application Field

Due to its excellent comprehensive performance, pultruded carbon fiber tubes have found wide applications in many high-tech and high-end industrial fields.

1. In the aerospace field, it is used to manufacture drone body structures, satellite brackets, aircraft interior support components, etc., fully utilizing its lightweight and high-strength characteristics to reduce launch or flight weight.

2. In the field of wind power generation, it is a key material for manufacturing large wind turbine blade main beams, providing enormous bending stiffness to resist wind loads, while reducing blade weight and improving power generation efficiency.

3. In the industrial field, it is used as a lightweight and high-strength structural support rod, robotic arm, roller, and conveyor system component to improve equipment speed and accuracy, and reduce energy consumption; Corrosion resistance is particularly important in chemical or offshore platforms.

Why Choose Us?

Buyer Review

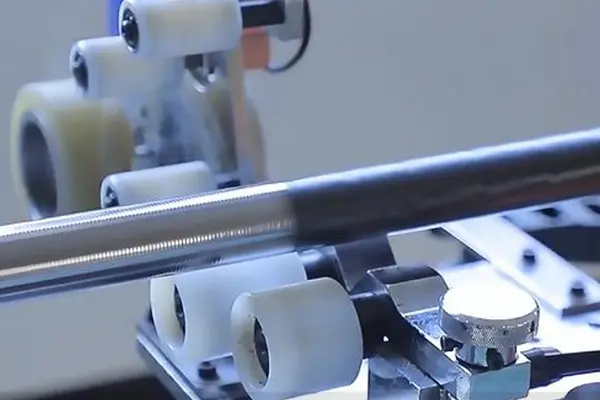

Our Factory

Packing & Transportation

FAQ

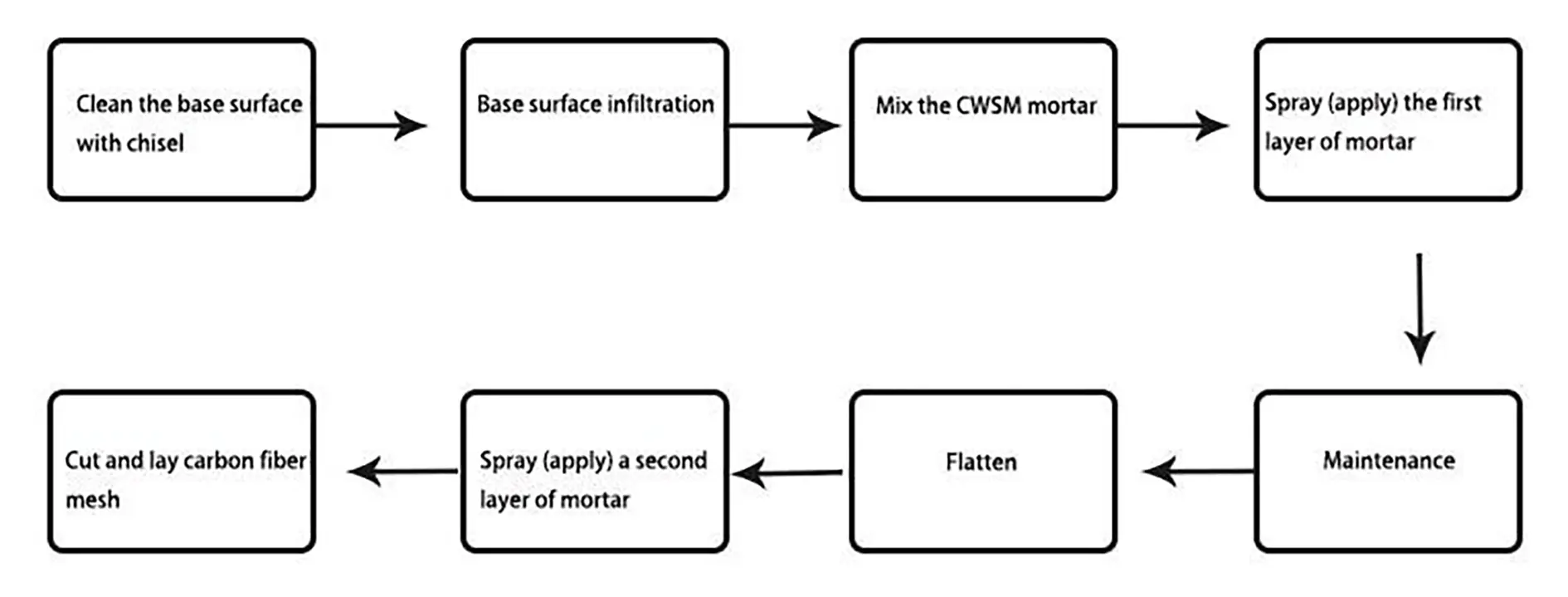

Flow Chart