High Strength Customized CFRP Carbon Fiber Rebar

Product Feature

1. Lightweight and high-strength: The density of carbon fiber reinforced rebar is about 1/4 of steel, but its strength is very high and can withstand large tensile forces.

2. Corrosion resistance: Compared to traditional steel bars, carbon fiber rebar has excellent chemical corrosion resistance and are not easily affected by environmental factors, making them suitable for harsh environments.

3. Low thermal conductivity: Its thermal conductivity is much lower than that of steel, which can effectively reduce structural deformation caused by temperature changes.

4. Flexible design: It can be designed in different shapes and lengths according to actual needs to meet various construction requirements.

|

Product Information |

|

|

Product Type |

Carbon fiber rebar |

|

Material |

100% carbon fiber and epoxy resin |

|

Diameter (mm) |

4~26 |

|

Density (g/cm3) |

1.6~1.8 |

|

Tensile Strength (MPa) |

1800~2200 |

|

E-modulus (GPa) |

140~150 |

|

Elongation (%) |

1.3~1.5 |

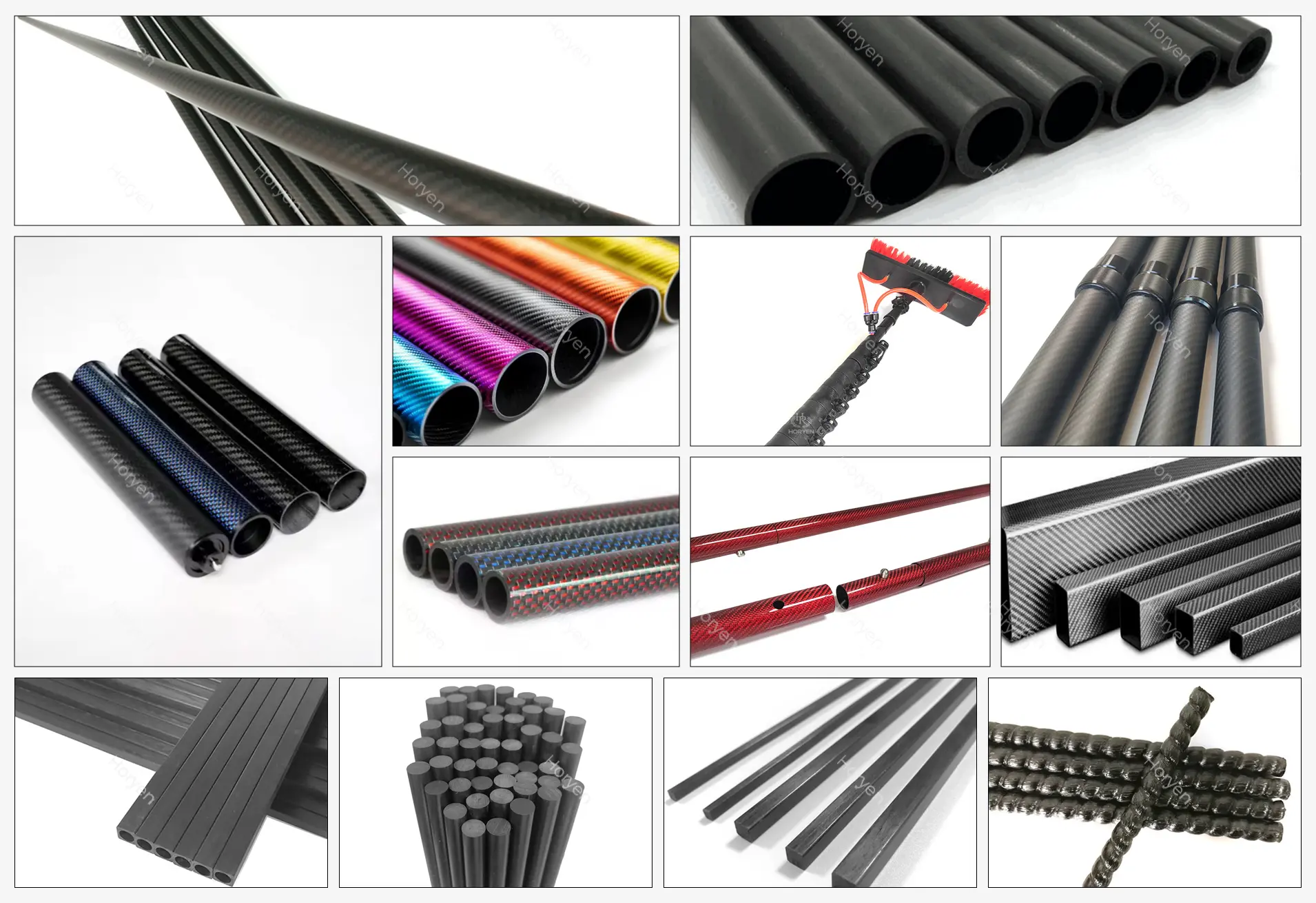

More Choice

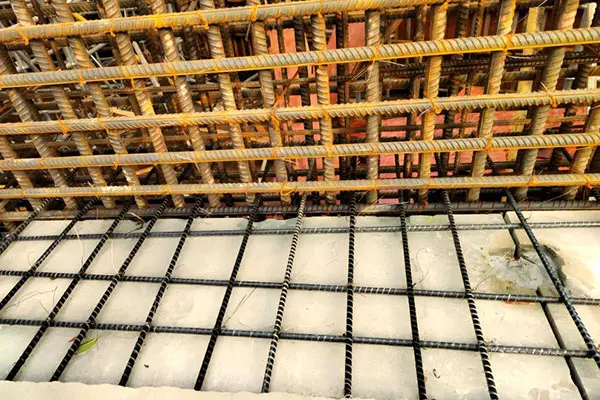

Application Field

● Construction engineering: can be used for high-strength and corrosion-resistant structures such as bridges, subways, tunnels, etc.

● Water conservancy facilities: suitable for buildings such as reservoirs and dam bodies, reducing the impact of poor water environment on materials.

● Road infrastructure: used as reinforcement materials for highways, airport runways, etc., to enhance load-bearing ability.

● Seismic engineering: Improving the safety and stability of buildings in natural disasters such as earthquakes.

● Ocean Engineering: Suitable for offshore platforms and other marine structures, resistant to seawater corrosion.

These applications demonstrate the diversity and efficiency of carbon fiber reinforced rebar in civil engineering, particularly with significant advantages in reducing weight, enhancing strength, lowering maintenance costs, and improving durability.

Why Choose Us?

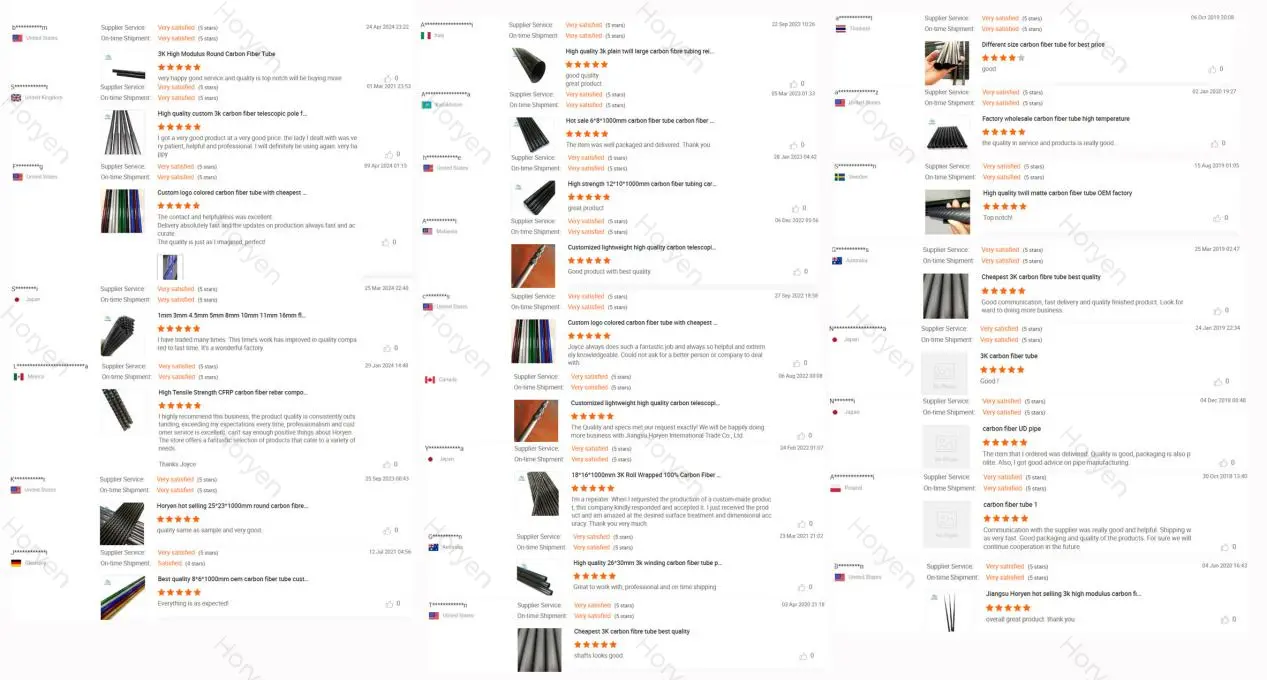

Buyer Review

Our Factory

Packing & Transportation

FAQ

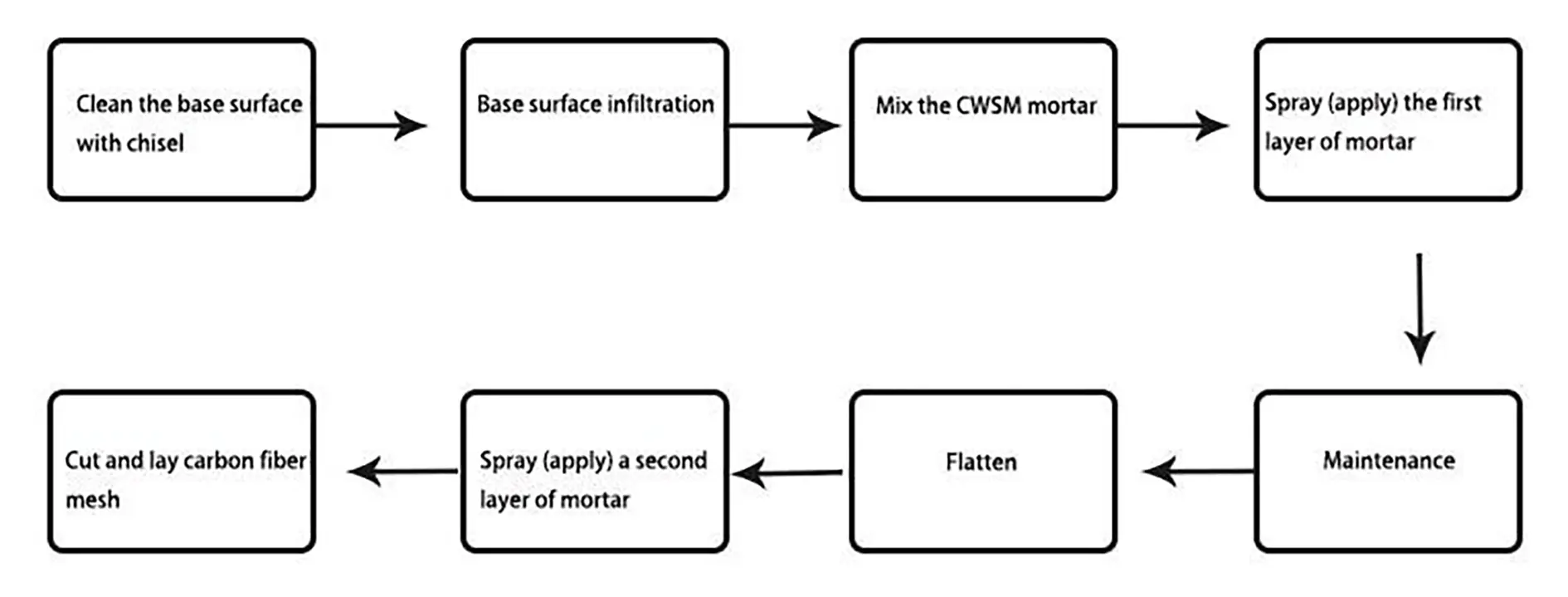

Flow Chart