01

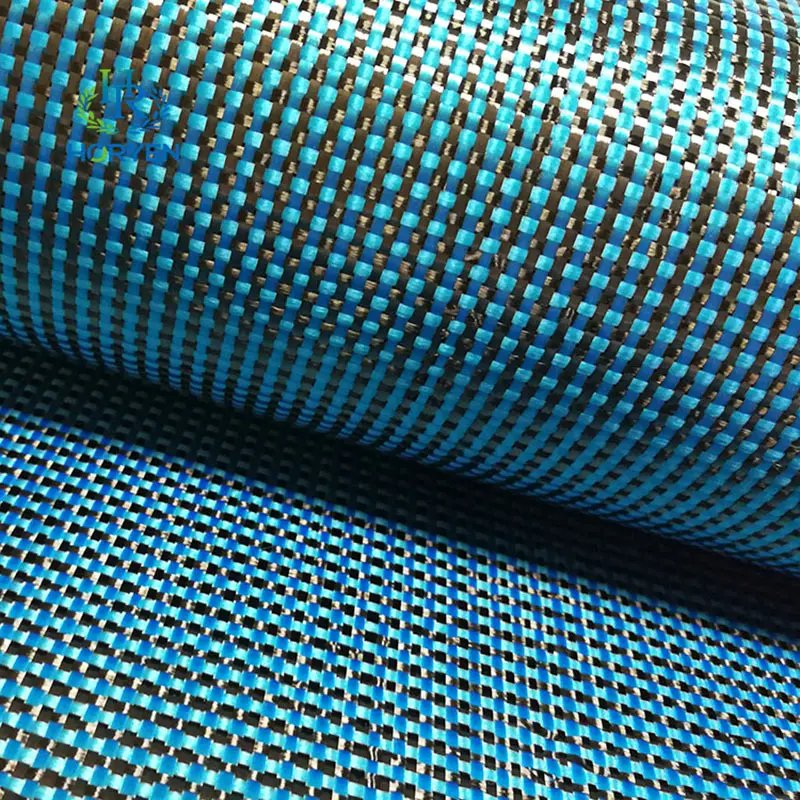

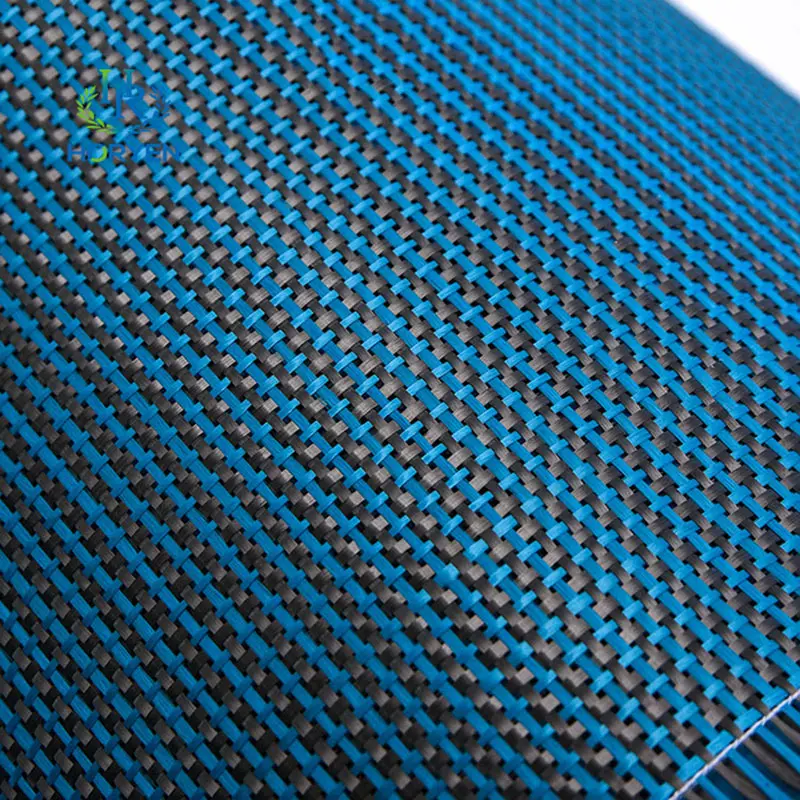

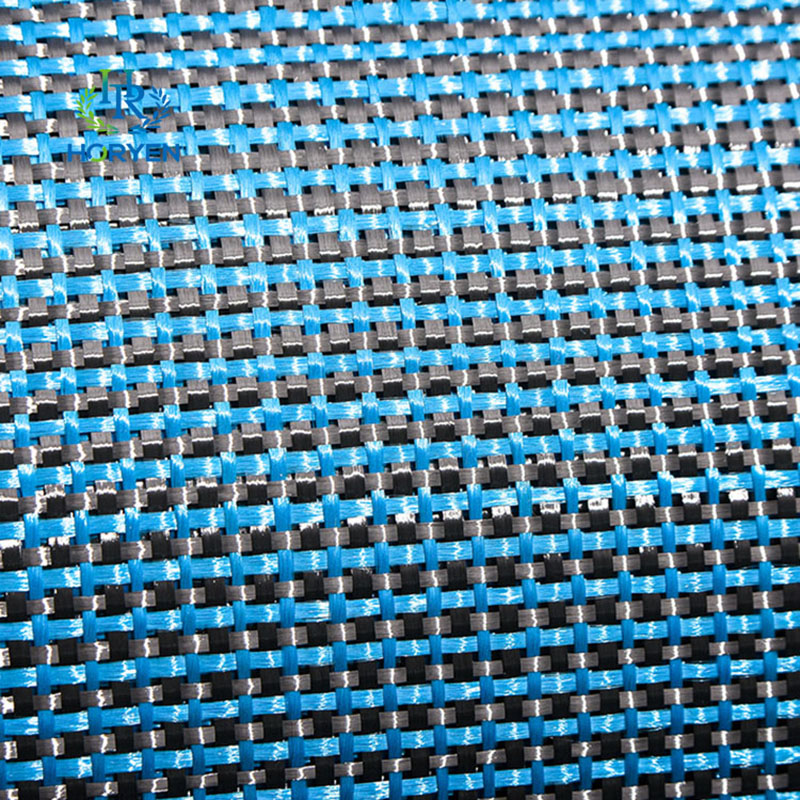

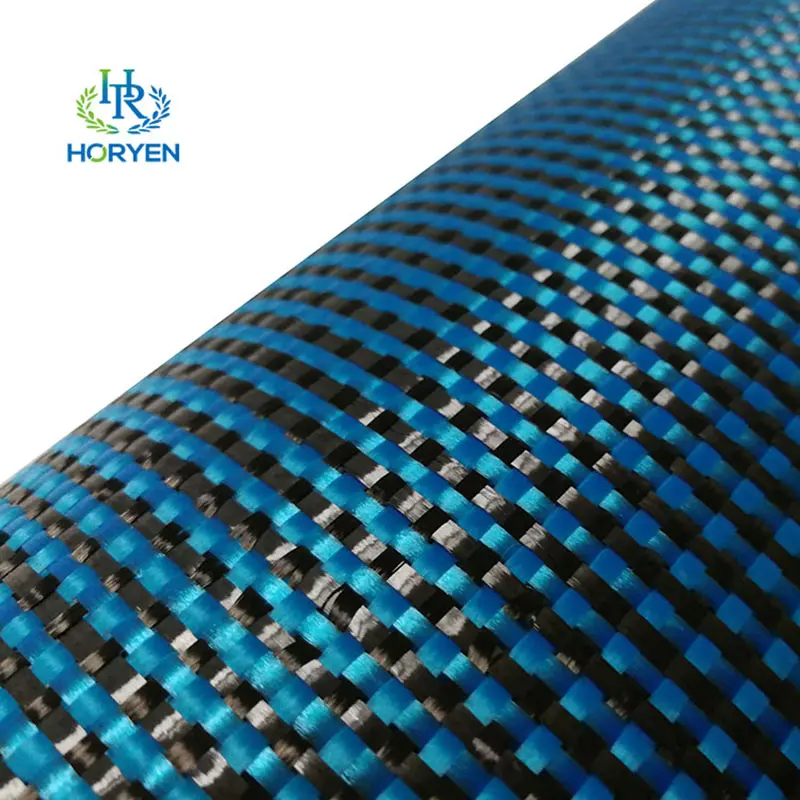

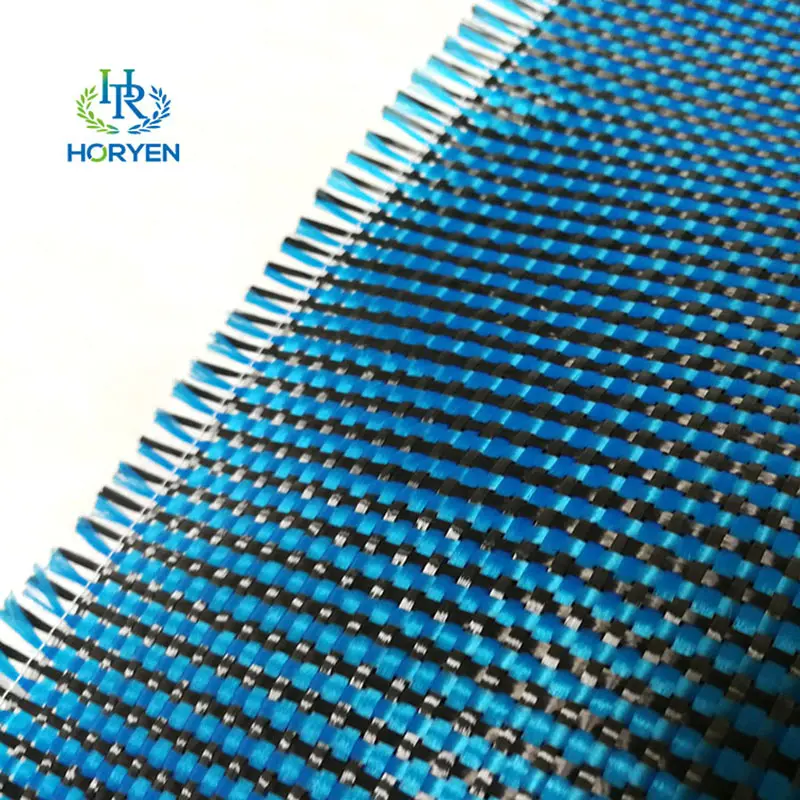

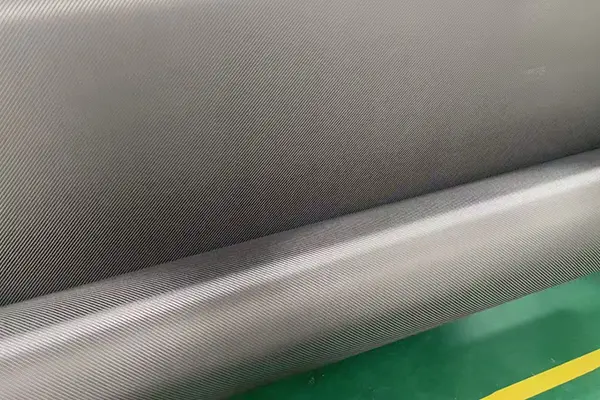

Light Weight 3k Lake Blue Hybrid Carbon Fiber Cloth

Product Feature

Advantages of carbon fiber: high specific strength (3.5-5 GPa), high modulus (200-400 GPa), and electrical/thermal conductivity.

Advantages of polypropylene fiber: good toughness (elongation at break>15%), chemical corrosion resistance (acid and alkali resistance), low cost, and low melting temperature (160-170 ℃).

Synergistic effect: Carbon fiber provides rigid load-bearing, polypropylene absorbs impact energy, and PP can achieve thermoplastic molding after melting (without high-temperature curing), suitable for rapid production.

|

Product Information |

|

|

Product Type |

Carbon Hybrid Fiber Fabric |

|

Material |

Carbon fiber and polypropylene fiber |

|

Fabric Type |

Cloth |

|

Warp |

3k |

|

FAW |

200g/m2 |

|

Thickness |

0.25mm |

|

Color |

Lake Blue |

|

Width |

100cm or customized |

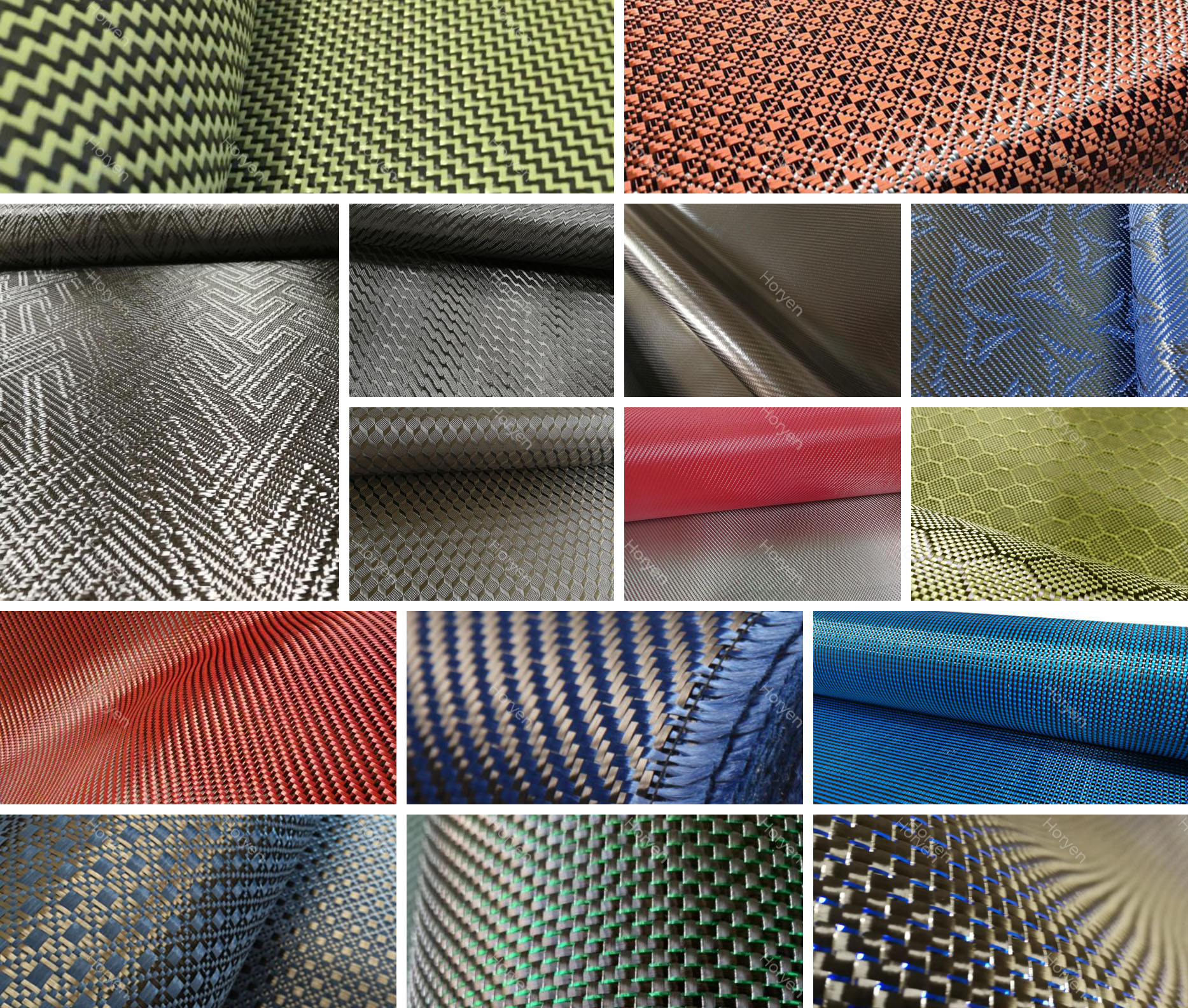

More Choice

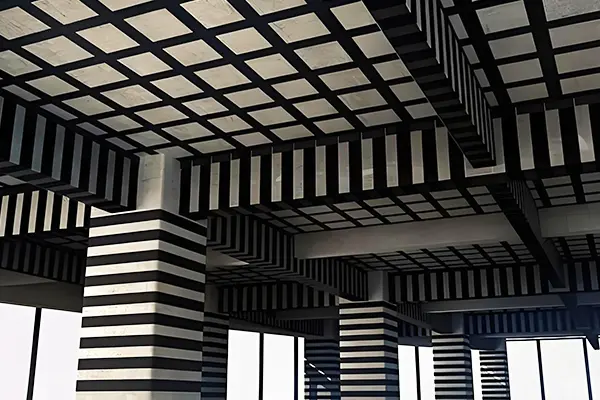

Application Field

Carbon fiber and polypropylene hybrid fabric achieves a balance between cost, performance, and sustainability through a design that combines rigidity and flexibility, making it particularly suitable for large-scale civilian products. Its core value lies in improving the performance of key parts with carbon fiber, achieving overall cost reduction and process simplification with PP, and having enormous potential in the fields of new energy vehicles, intelligent wearables, and more in the future.

Automotive lightweighting:

Consumer Electronics:

●Door inner panel and seat frame (reduced by 30% to meet collision energy absorption requirements).

●Battery pack shell (PP resistant to electrolyte corrosion+carbon fiber conductive anti-static).

Consumer Electronics:

●Laptop shell (surface carbon fiber texture+PP inner layer anti drop).

●Drone bracket (high rigidity+low cost).

Industrial sector:

●Chemical pipeline lining (acid and alkali resistant+pressure resistant).

●Logistics tray (can be thermoplastic repaired, with a lifespan extended by 2 times).

Sports equipment:

●Bicycle pedal (carbon fiber wear-resistant layer+PP shock-absorbing substrate).

●Ski board core material (low temperature toughness -40 ℃ without brittle fracture).

Why Choose Us?

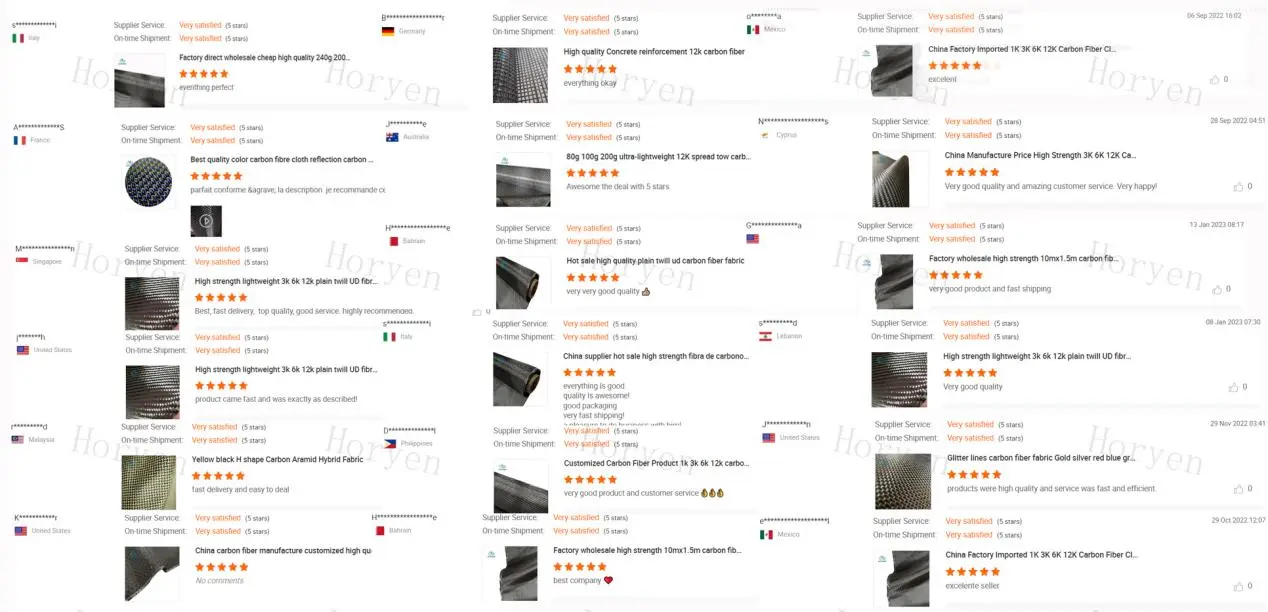

Buyer Review

Our Factory

Packing & Transportation

FAQ

Product Parameter

| Product Information | |||||

| Product Type | Carbon aramid Fiber Fabric | ||||

| Material | Carbon fiber and aramid fiber | ||||

| Fabric Type | Cloth | ||||

| Warp | 3k | ||||

| FAW | 200g/m2 | ||||

| Thickness | 0.25mm | ||||

| Color | Yellow | ||||

| Width | 100cm or customized | ||||