Breakthrough in high refractory carbon fiber laminated board: protective interlayer

The fire resistance of carbon fiber laminated sheet depends on the type and properties of the resin used. By designing the laminate, the fire resistance of the laminates can also be effectively improved.

Researchers from the German Federal Agency for Research and Testing of Materials (BAM) have proposed a fire prevention method, which involves adding protective interlayers to carbon fiber reinforced polymer (CFRP) laminates.

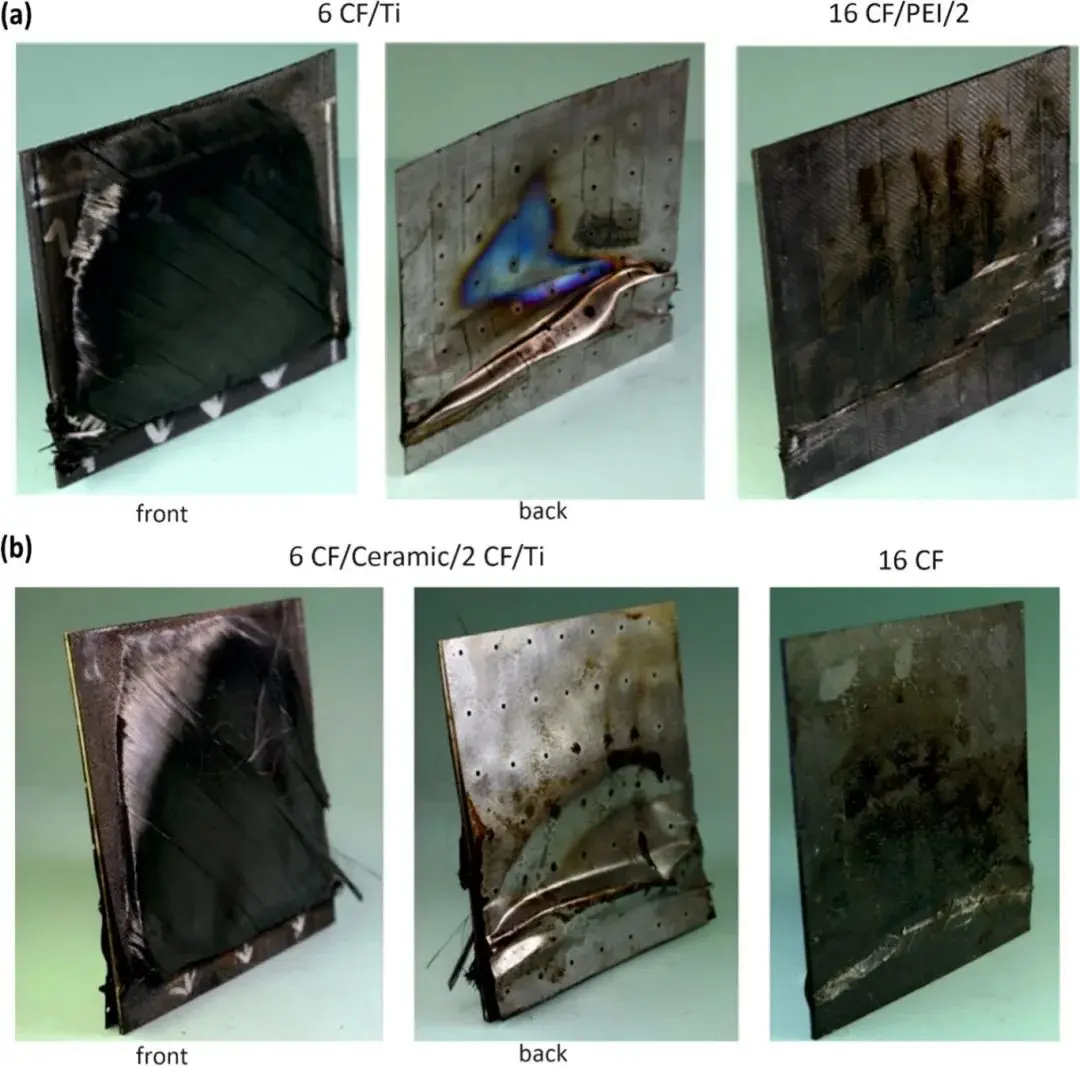

The study validated six different CFRP laminating systems using five different protective interlayers. The laminated structure is specially designed to consist of a laminated board consisting of 8 layers of carbon fiber layers (divided into two parts: 6CF and 2CF) and 2 layers of protective interlayer.

Using the same material at two different positions in two systems can investigate how the position of the protective layer in a laminated structure affects the results. Ceramic composite materials have been applied as the first protective layer in three different systems. Although the working temperature limit of basalt fibers is relatively high (700 °C), the laminated board using basalt felt has the thinnest thickness and the shortest failure time.

Although the failure time is relatively short, the temperature measured on the back of the CFRP/ceramic/basalt layer pressing plate is 77.8 °C, which is the same as the temperature of the rubber cushion pressing plate, which was exposed to fire for an additional 30 seconds. Although the thickness of CFRP/ceramic/rubber specimens is the largest, their failure time is significantly longer than that of CFRP/ceramic/cobalt laminates. From this, it can be seen that compared with other protective interlayers, titanium foil has stronger structural integrity and can exhibit excellent performance even if the thickness is similar.