Forming process of carbon fiber composite materials

The cables used for the lifting of the Hong Kong Zhuhai Macao Bridge consist of a total of 140000 high-performance polyethylene fibers, with the aim of lifting approximately 6000 tons of steel structure concrete prefabricated components to complete the final joint of the underwater tunnel of the Hong Kong Zhuhai Macao Bridge Island Tunnel Project.

Hand lay up molding process

Hand lay up process refers to a molding method in which reinforcing materials and thermosetting resins are laid on molds by hand or with mechanical assistance, and the resin is cured to form composite materials. Manual tiling mainly uses two types of materials: unidirectional prepreg tape and fabric prepreg. Unidirectional prepreg can be used to lay complex shapes, but it has a high rate of cutting waste. Compared to unidirectional prepreg, fabric prepreg has lower labor intensity but lower performance. Meanwhile, the common disadvantage of hand lay up molding is that it is difficult to lay large-sized components.

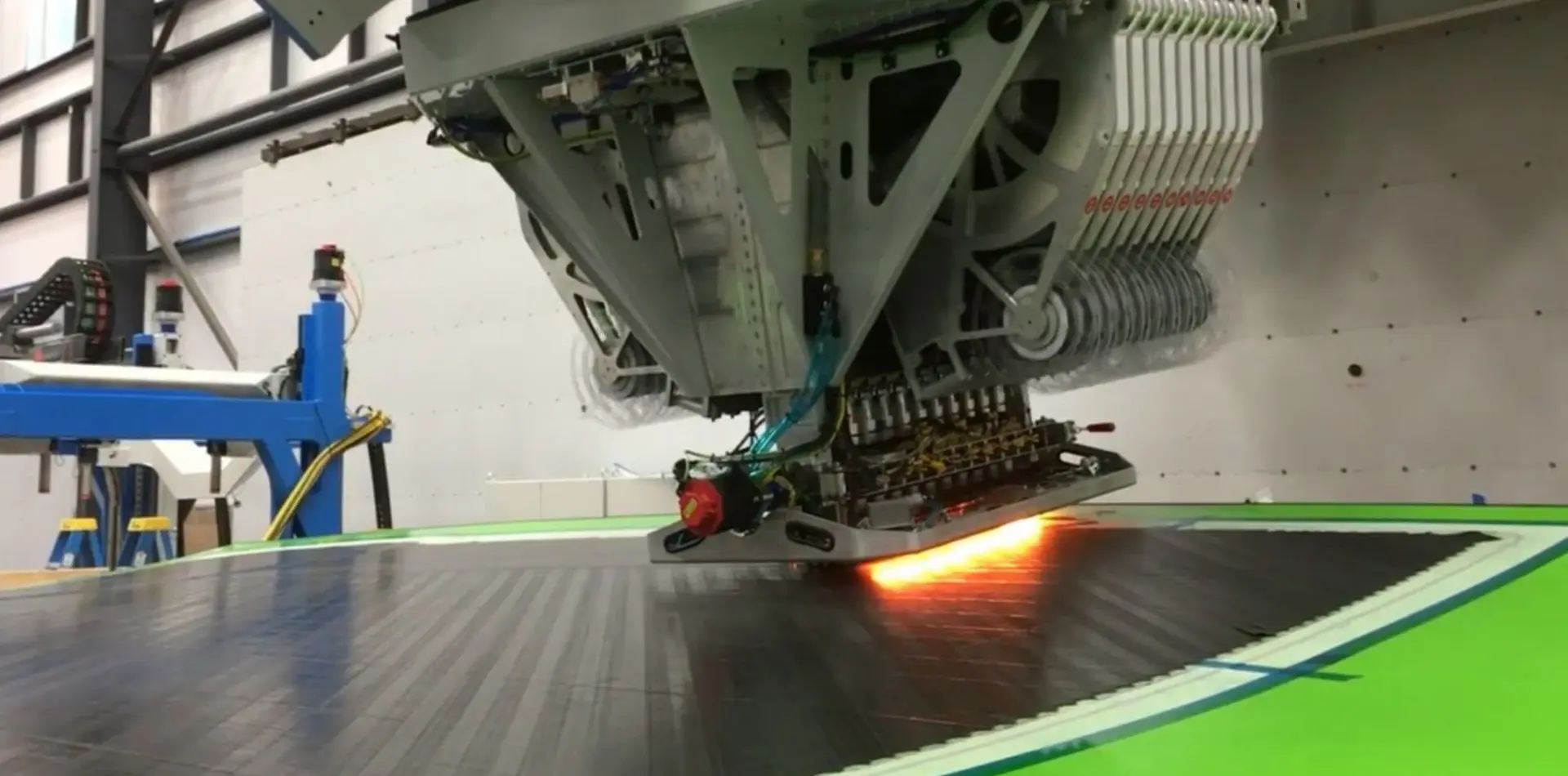

Automatic laying process

Suitable for flat plates or components with uniform thickness changes or simple shapes, with high production efficiency, low laying costs, automatic cutting, reduced cutting waste during layer laying, and no need for vacuum compaction. Automatic tiling can also be applied to curved surfaces with shapes, with precise control of layer thickness, low void content of less than 1%, and unrestricted fiber angles. But the cost is too high, mainly used for the production of large-scale industrial composite parts (such as wings).

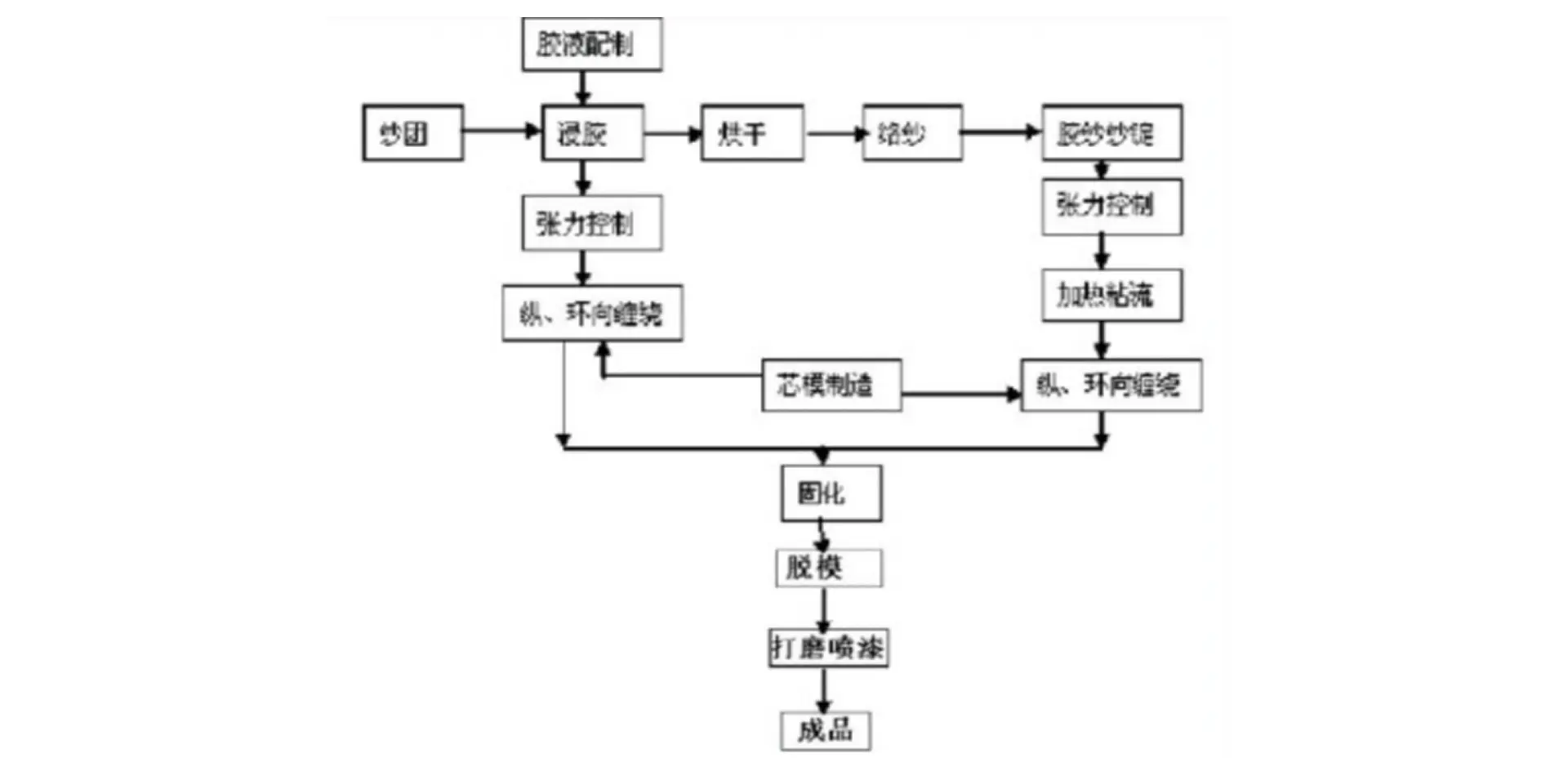

Wrapping forming

Winding molding is divided into dry winding, wet winding, and semi dry winding. Suitable for rotating bodies (cylindrical shells and sealed containers); Production automation, high efficiency, and low cost; High fiber volume content.

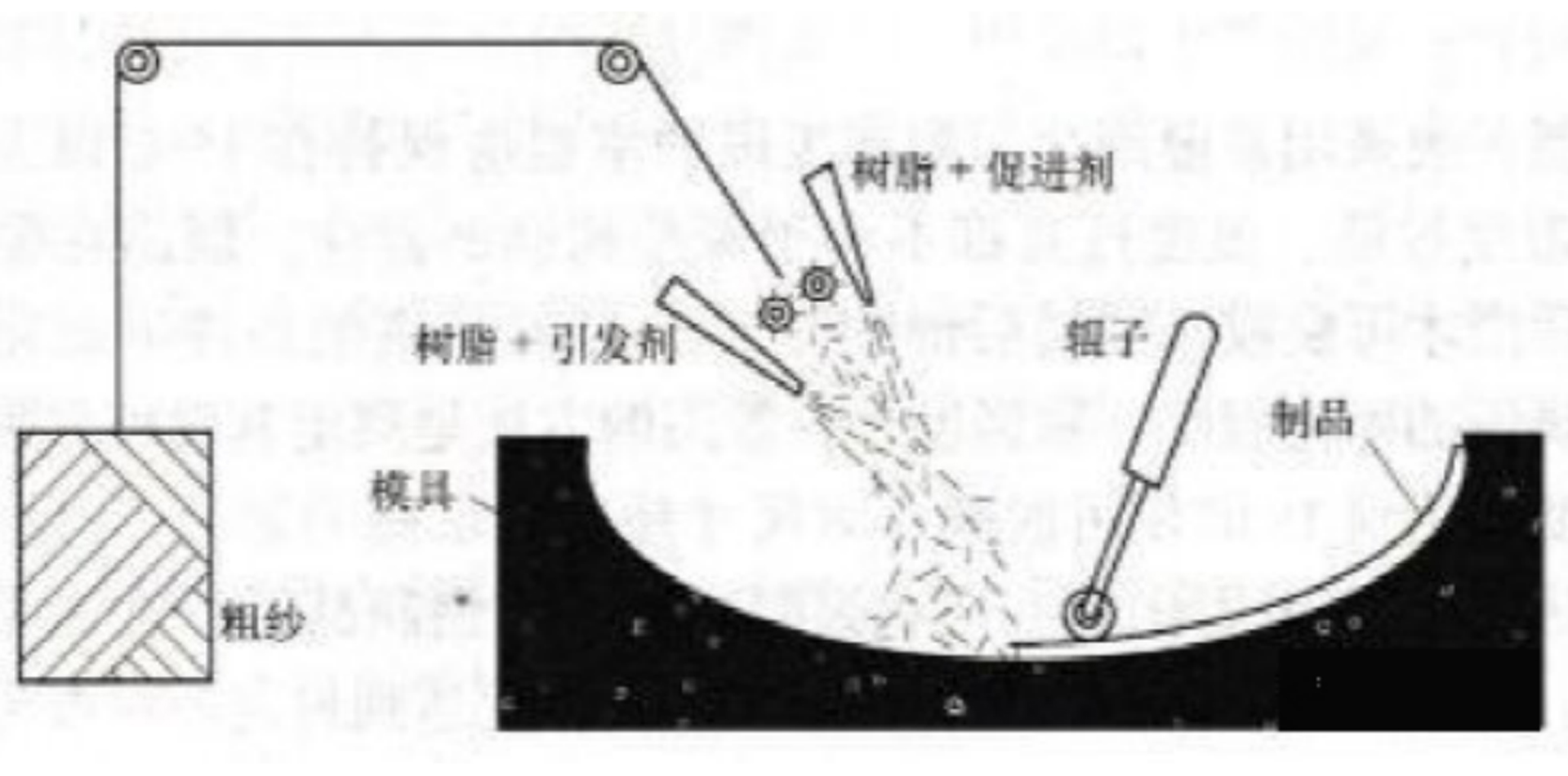

Spray molding

The principle of spray molding is to simultaneously spray the resin system and short fibers (or whiskers, particles) onto the mold to form composite material parts. This process involves spraying a resin system containing a curing agent and a resin system containing an initiator from two nozzles of a spray gun into the mold cavity, while also using a cutter on the spray gun to cut continuous fibers into short fibers. After spraying to the specified thickness, use a roller to compact it and then cure it into a molded product.

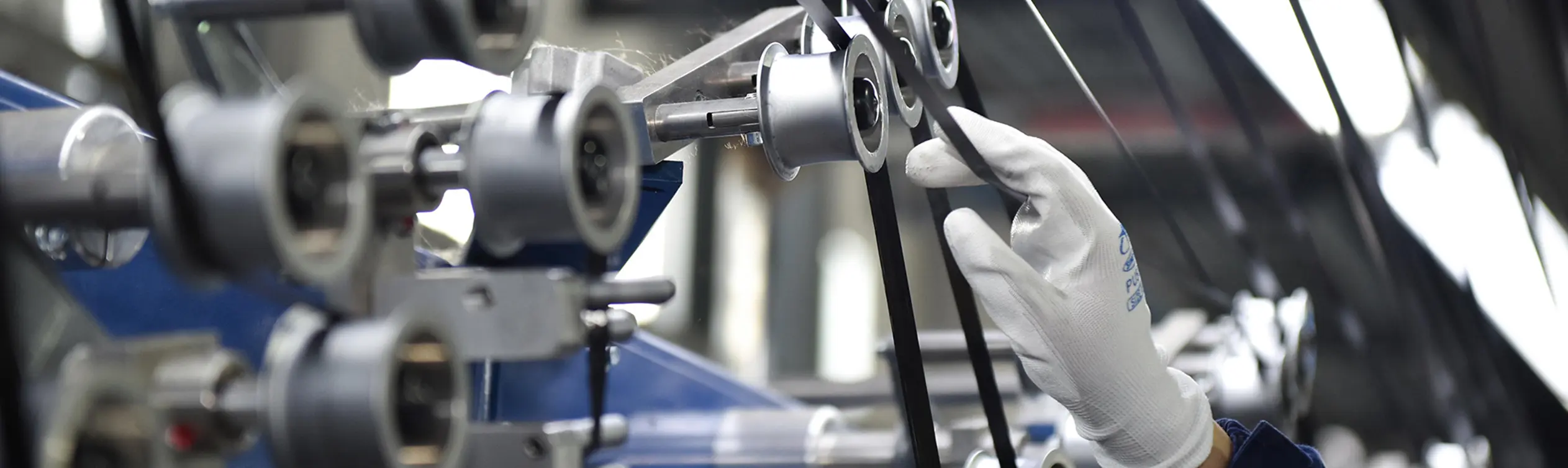

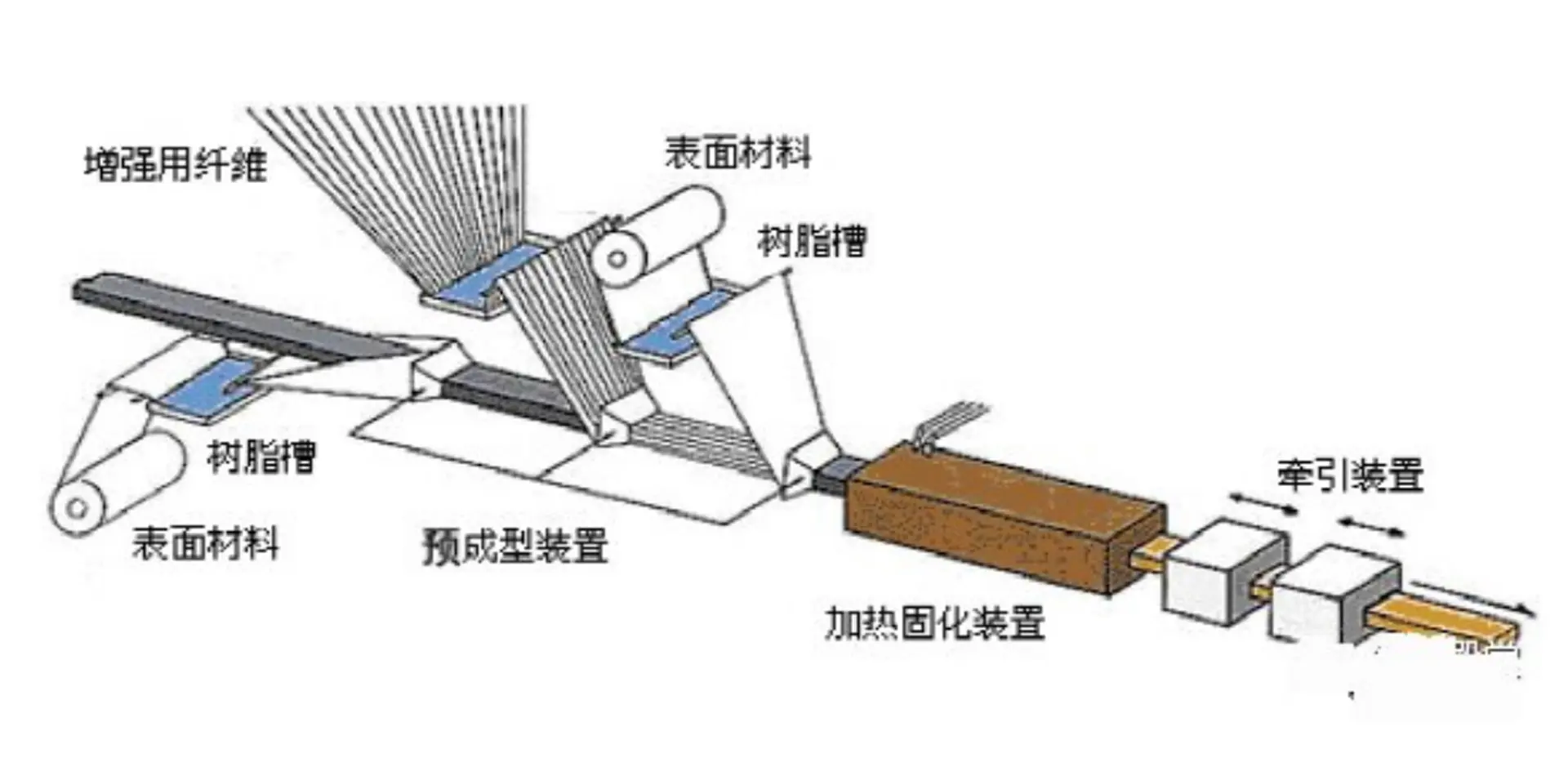

Pultrusion molding

The composite material extrusion molding process is a method of producing composite profiles by immersing continuous fibers or their fabrics in resin under the traction of traction equipment, and heating the resin through a molding mold to cure the resin. The process flow of extrusion molding technology can be briefly divided into three steps: infiltration, molding, and curing/cooling.

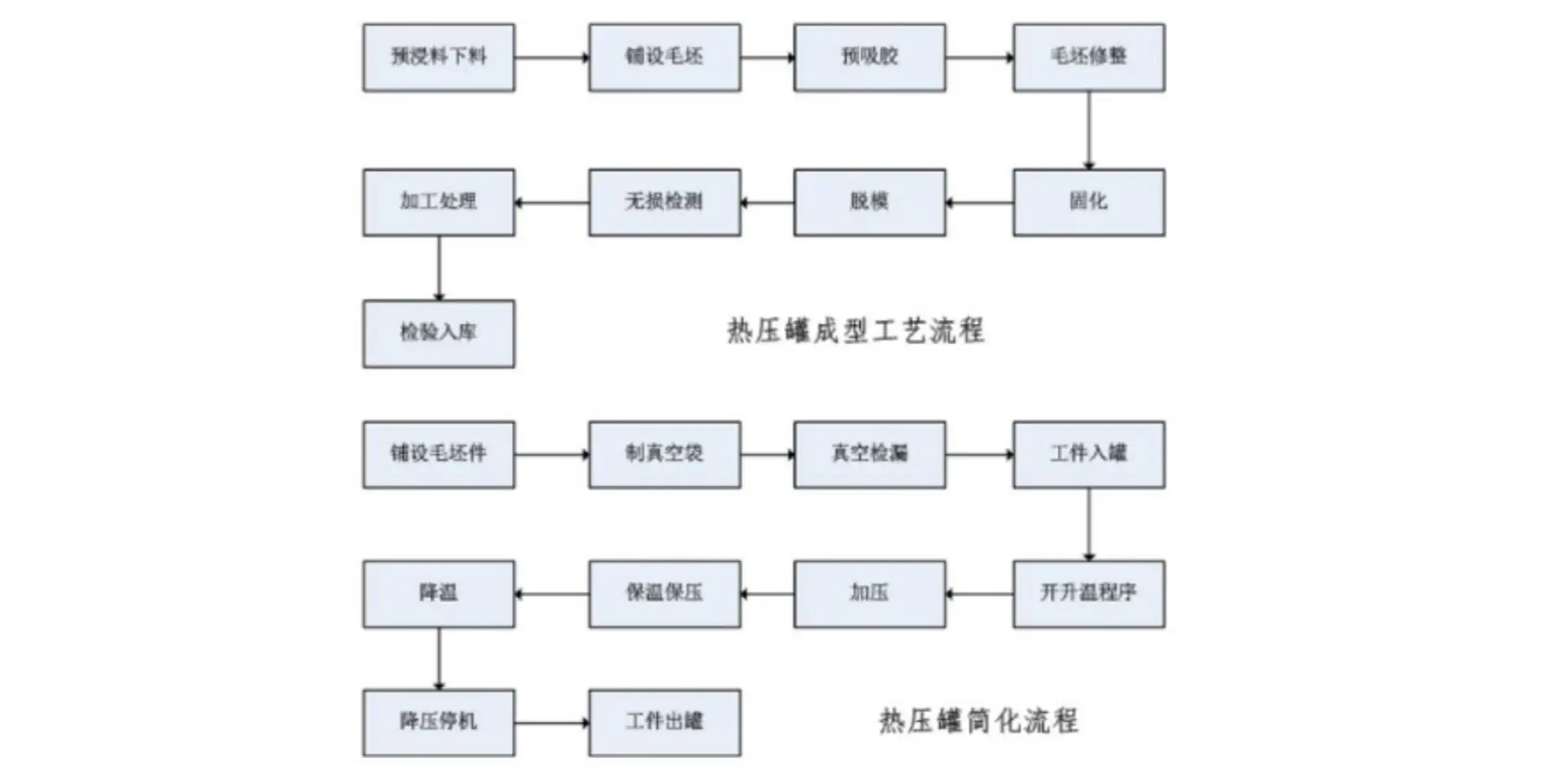

Autoclave forming

The hot press can forming process is a method of forming composite material blanks, honeycomb sandwich structures, or bonded structures by sealing them in a vacuum bag on a mold. In the hot press can, under vacuum (or non vacuum) conditions, they are heated, pressurized, insulated (medium or high temperature), cooled, and depressurized to achieve the desired shape and quality.

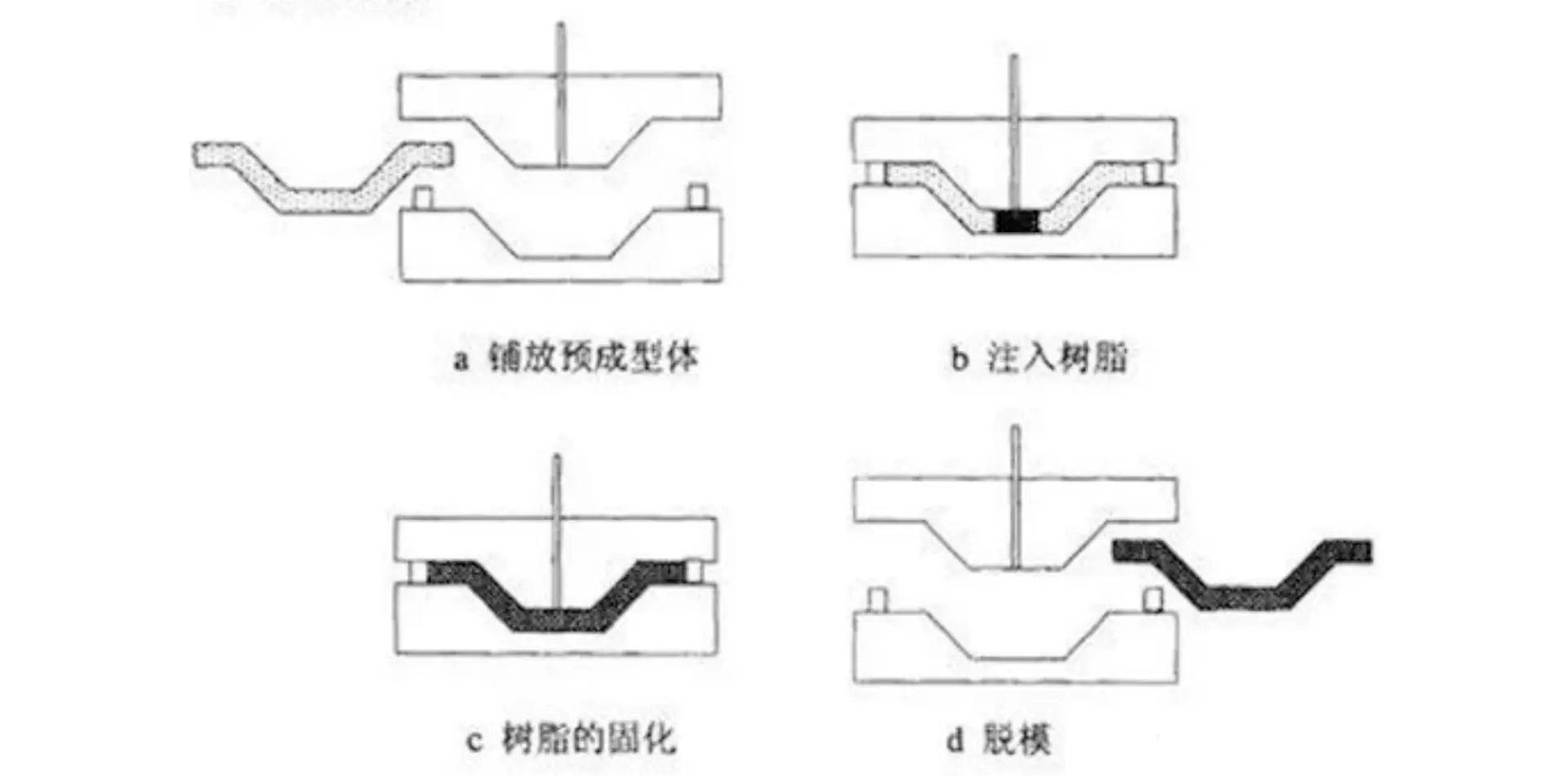

RTM molding

Under the conditions of pressure injection or external vacuum assistance, a low viscosity liquid resin with reactive activity is made to flow in a closed mold and eliminate gas, infiltrating and impregnating the dry fiber body. The resin undergoes cross-linking reaction through heat in the mold to complete solidification.

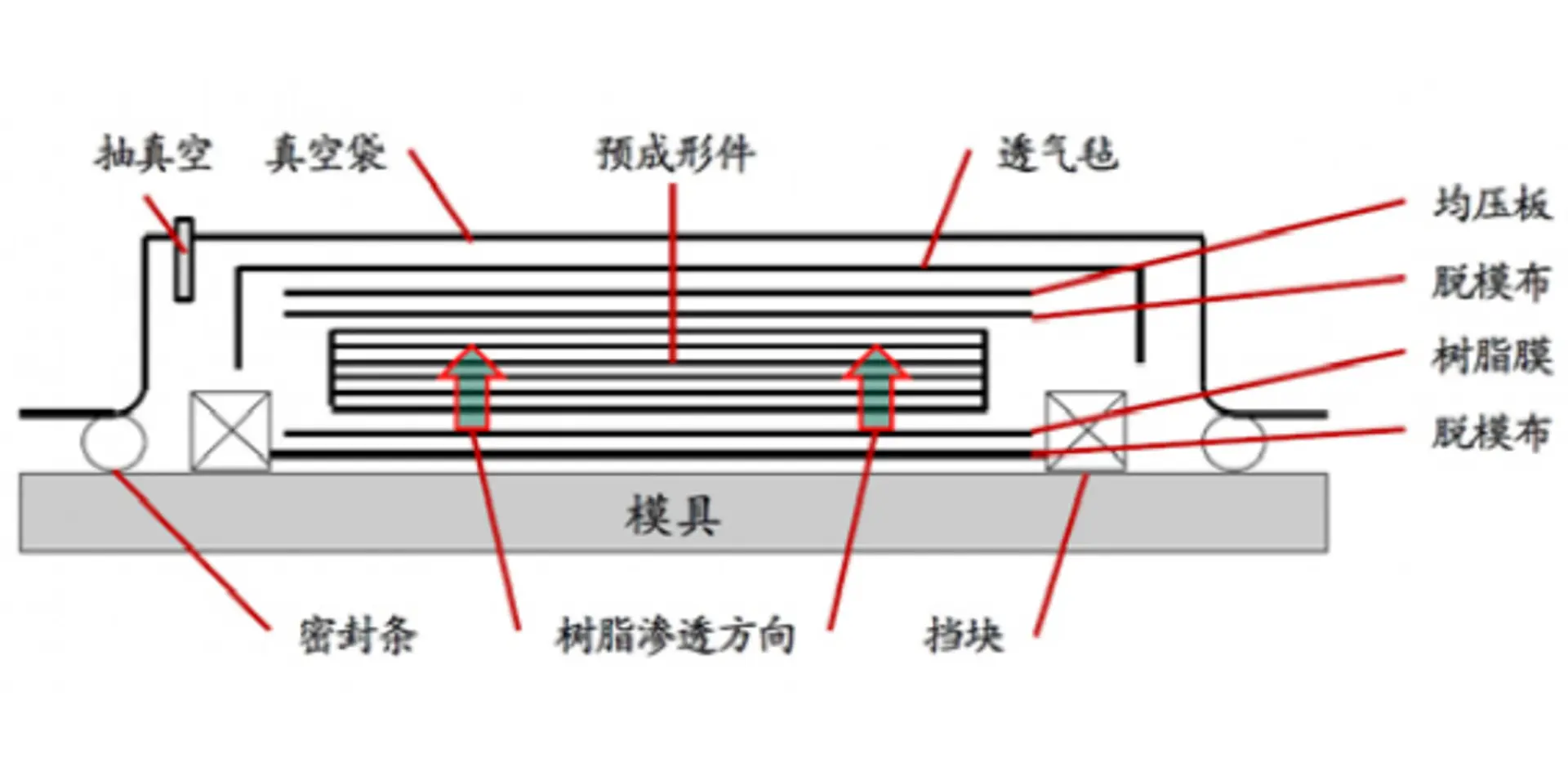

RFI molding

Solid or semi-solid resin film is placed under the dry fiber body, and the resin penetrates from the bottom to the top, saturates the fibers and exhausts, completing solidification in the saturated state.