The Gift of Nature - Basalt Fiber

industrial wastewater or exhaust gas generation, and it has high added value, earning it the title of "green new material" in the 21st century. Due to its golden brown color, the process of producing basalt fibers is known as "turning stones into gold".

With the advancement of technology and market demand, basalt fibers are made into various products, such as basalt fiber fabric, unidirectional Basalt Fabric, basalt fiber chopped strand, basalt composite board, and so on. Basalt has transformed from an unknown stone into a new type of material that is green, low-carbon, energy-saving, environmentally friendly, and sustainable.

The most commonly used basalt fiber is in the field of construction, and over time, various problems may arise in building structures, among which cracks are the most common. Cracks not only affect the aesthetics of buildings, but more importantly, they can affect their structure and safety.

Basalt fiber roving is a basalt fiber product made by combining multiple parallel strands or a single parallel strand without twisting.

Basalt fiber short cut yarn is a product made by cutting continuous basalt fiber strands. It is the preferred material for reinforcing thermoplastic resins and also the best material for reinforcing concrete.

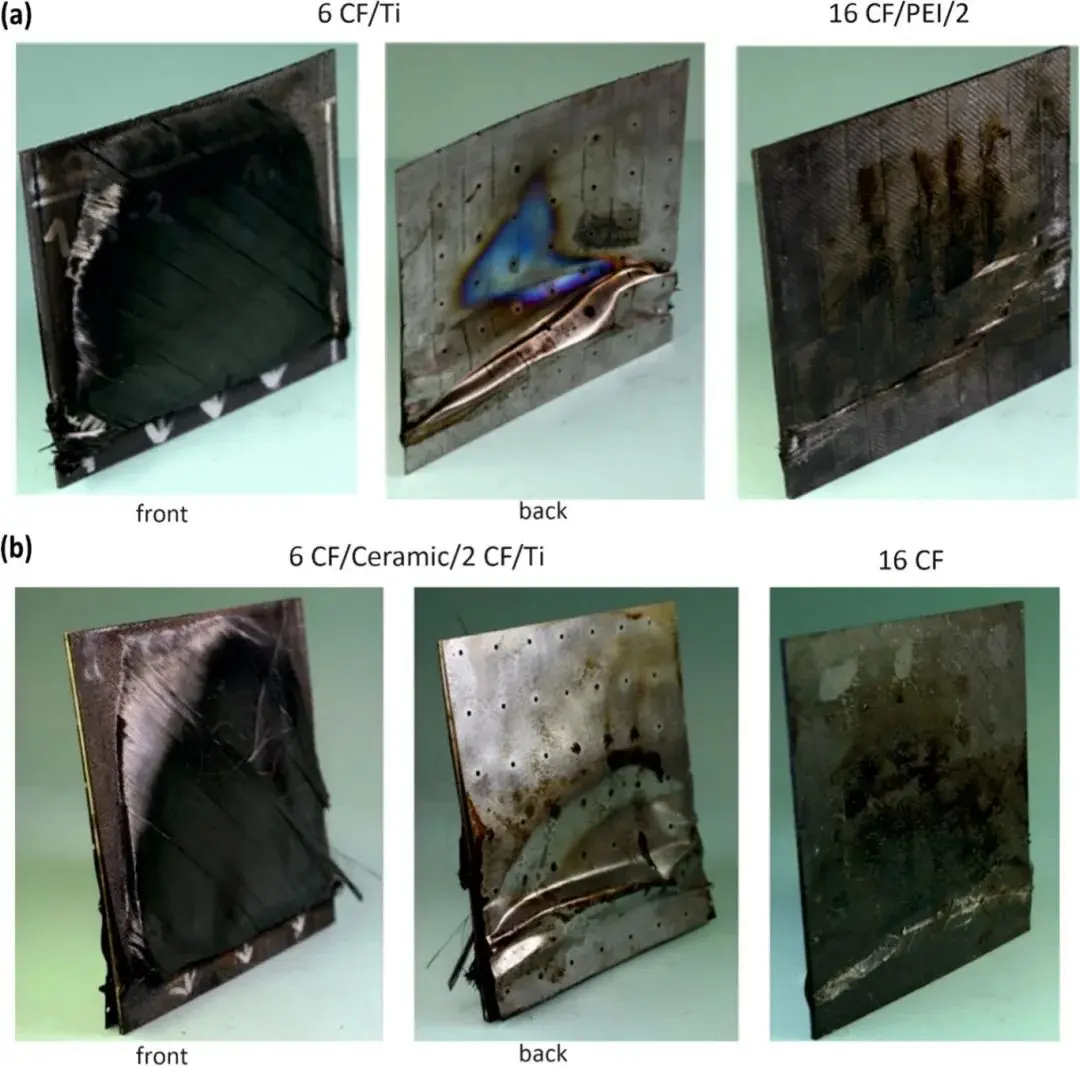

Therefore, it is crucial to carry out crack resistance reinforcement and maintenance on building structures. In this regard, Basalt Fiber Cloth, as a new type of building material, has many unique advantages and application potential.

Basalt fiber cloth can be used for the reinforcement and maintenance of bridges, effectively improving their bearing capacity and crack resistance performance.It can be used for tunnel reinforcement and maintenance, improving the structure and safety of the tunnel.

At the same time, it is also possible tocan also be used for reinforcement and maintenance of other civil engineering projects, such as roadbeds, embankments, etc.