Anti Cutting 300gsm Elastic White UHMWPE Fiber ...

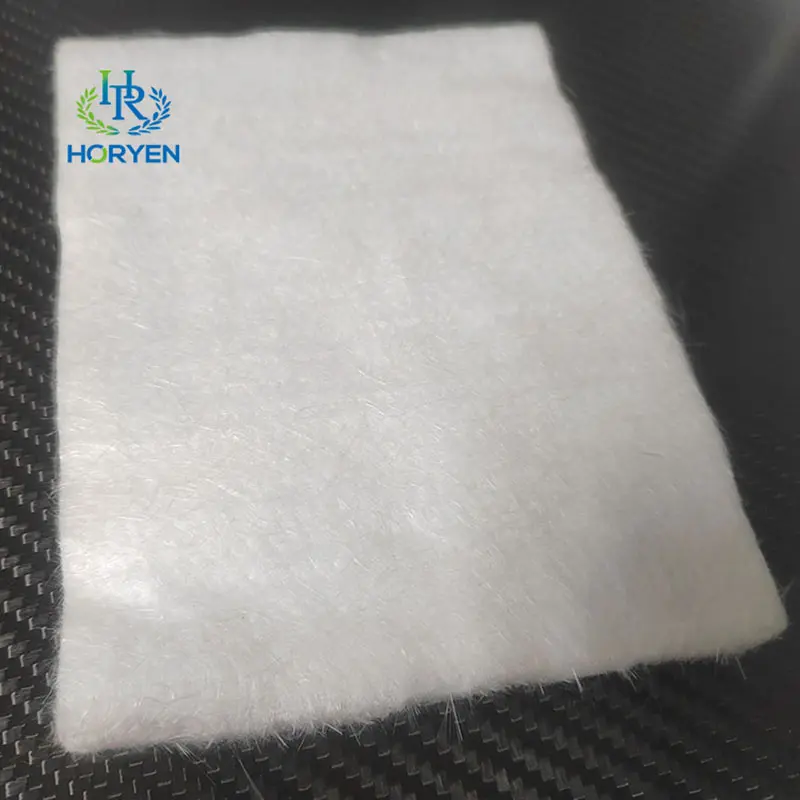

Anti cutting UHMWPE fiber fabric is a high-grade textile material made of ultra-high molecular weight polyethylene (UHMWPE) fibers. UHMWPE is a high-performance polymer with a molecular weight typically above 3 million, endowing the material with extremely high strength and toughness. The production process of cut resistant fabric usually involves high-density weaving, which gives the fabric excellent tear resistance and wear resistance. This fabric is processed during the production process to ensure it has a certain degree of waterproofing and breathability, while maintaining a lightweight and soft touch.

High Strength Wear-Resistant Cut Proof Uhmwpe F...

Cutproof UHMWPE fiber fabric is made of high strength and high modulus polyethylene( UHMWPE ).it could be widely used in manufacturing industry, automotive industry and other fields.UHMWPE fabrics make products lighter and more comfortable without compromising on strength and durability.

The principle of fabric anti cutting is to use the material and structural characteristics of the fabric itself to make it resistant to cutting tools. In terms of gloves, Cut resistant fabric can increase the service life and safety of gloves. In terms of vehicle seats, fabric anti cutting can improve the safety of personnel inside the vehicle.In terms of industrial and outdoor products, it is used to manufacture ropes, cables, fishing nets, etc., suitable for marine engineering and outdoor activities.

High Quality Cut Resistant Stab Proof UHMWPE Cloth

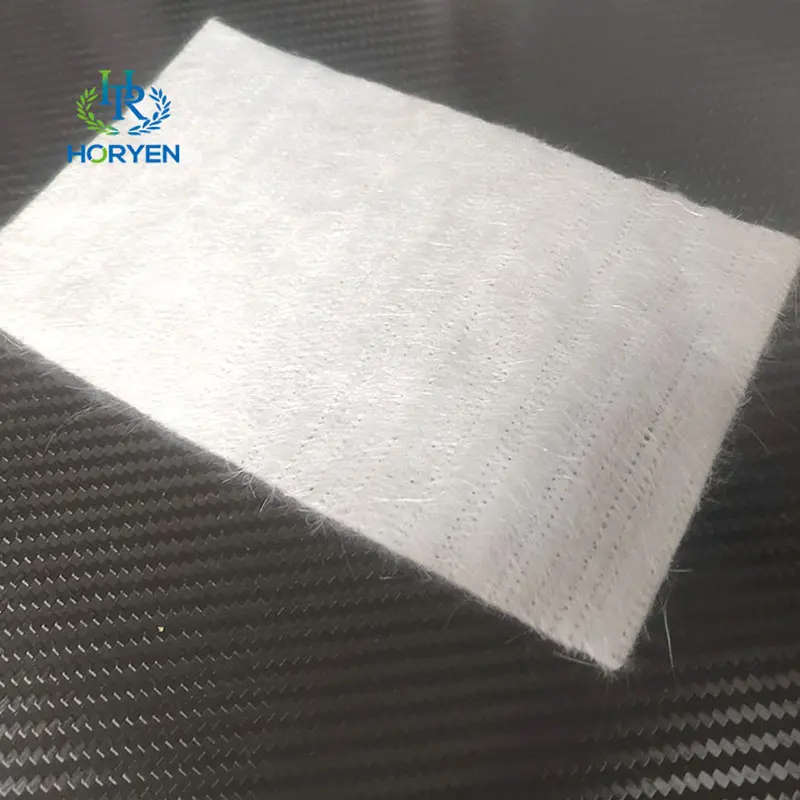

It is an ultra-high cut resistant fabric, aramid fiber and ultra-high molecular weight polyethylene (UHMWPE) fiber are both high strength, cut resistant materials. It could be widely used in cut resistant gloves, cut resistant clothing, anti bite clothing, Anti-theft package, Extreme athletic wear, Animal protective clothing and other fields.

The specific strength is more than ten times that of steel wires with the same cross-section; The specific modulus is second only to high-grade carbon fiber; The elongation at break is higher than that of carbon fiber and aramid, with good flexibility and great advantages in lightweight composite materials.

UD fabric proof UHMWPE fabric for vest

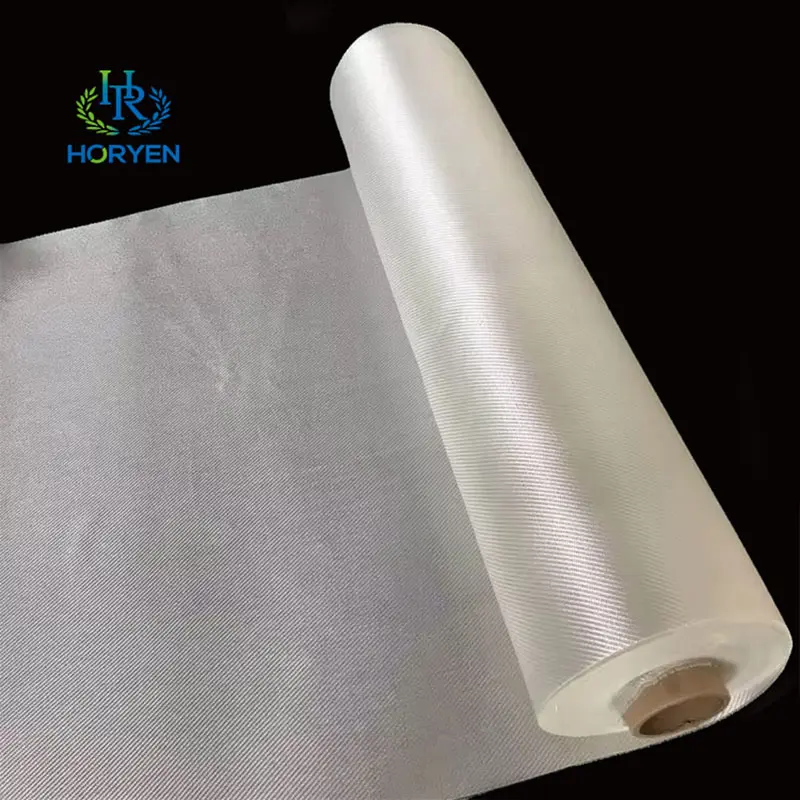

Unidirectional UHMWPE (ultra-high molecular weight polyethylene) fabric is a special material made of ultra-high molecular weight polyethylene fibers, using a unidirectional fiber structure. The production process of this material includes arranging UHMWPE fibers in a specific direction and processing them to form a fabric with high strength and low density.

The fiber molecular chains of unidirectional UHMWPE fabric are very long, endowing it with excellent structural strength and tear resistance. During the manufacturing process, the arrangement of fibers gives it excellent tensile resistance in a specific direction, thereby enhancing its overall physical properties. This material is commonly used to manufacture bulletproof products, such as bulletproof vests, to provide users with a certain degree of safety protection.

160gsm UD UHMWPE Fiber Fabric Sheet For Body Sa...

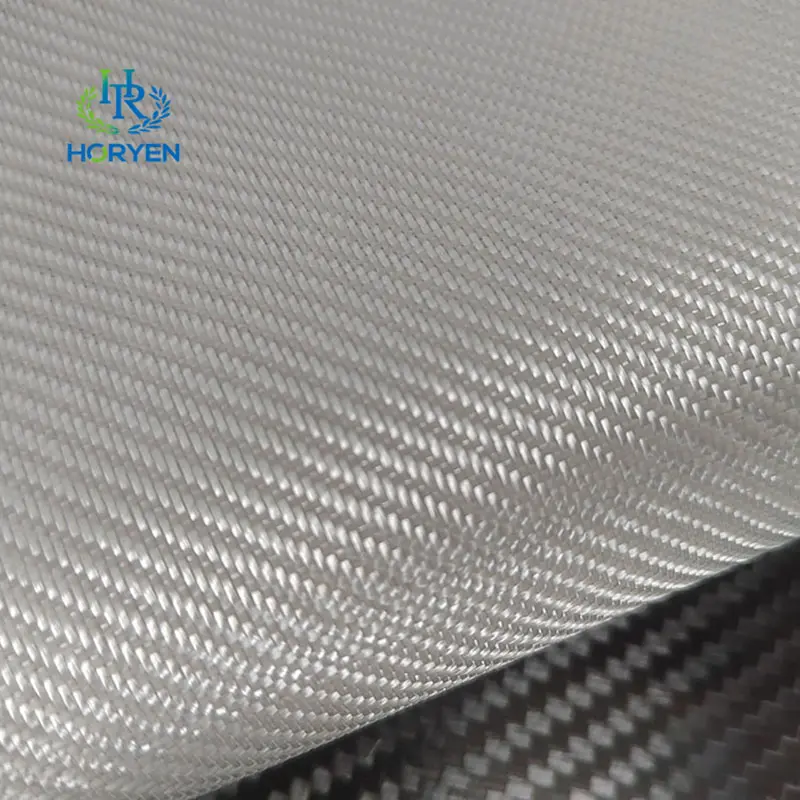

UD UHMWPE fiber fabric is a type of fabric made from ultra-high molecular weight polyethylene (UHMWPE) fibers, characterized by a unidirectional arrangement of fibers, meaning all fibers are oriented in one direction. This special structure gives this fabric high strength and toughness in a specific direction.

UD UHMWPE fiber fabric is typically made by combining high-strength UHMWPE fibers with advanced weaving techniques to ensure its uniformity and consistency during the production process. Due to its unique production process, the physical properties of UD UHMWPE fiber fabric can be adjusted as needed.

Stab-proof 130gsm Ultra-high Molecular UHMWPE U...

UHMWPE fiber fabric, also known as ultra-high molecular weight polyethylene fabric, is a textile material made from ultra-high molecular weight polyethylene fibers. Its manufacturing process usually involves spin and weaving ultra-high molecular weight polyethylene to form fabrics with certain strength and toughness. UHMWPE fiber fabric can undergo different treatments and processing during the production process to achieve the desired structural and performance characteristics.

This type of fabric typically has high tensile strength and wear resistance, and its molecular structure gives it excellent tensile and tear resistance. By using different weaving methods, UHMWPE fiber fabric can form different fabric structures to meet different usage needs. The fabric produced usually exhibits lightweight and soft characteristics, making it easy to process and shape.

75g UD UHMWPE Fiber Cloth For Sale

UHMWPE fiber cloth is a type of fabric made from ultra-high molecular weight polyethylene (UHMWPE) fibers. It has a high molecular weight, typically exceeding 300000, which makes it significantly different in structure and performance from ordinary polyethylene fibers. UHMWPE fiber cloth is manufactured through spin process to form fibers with high strength and good wear resistance, and after weaving or other processing, it forms a flexible and sturdy fabric. This fabric has high tensile strength and good chemical resistance, making it a unique high-performance material.

High Strength 80g UHMWPE Fiber Fabric Ballistic...

UD UHMWPE fiber fabric, also known as ultra-high molecular weight polyethylene fiber fabric, is a high-performance protective material made of ultra-high molecular weight polyethylene fibers. It uses a special weaving process to form a fabric with extremely high strength and good toughness, which is widely used in the manufacturing of ballistic equipment and protective clothing.

During the production process, this material undergoes high-temperature and high-pressure treatment to form tight connections between fibers, significantly improving its impact resistance and toughness. UHMWPE ballistic fiber fabric not only has extremely high strength, but also has good chemical resistance and wear resistance, allowing it to maintain excellent performance even in harsh environments.

75gsm 130gsm 160gsm PE UD UHMWPE Fiber Ballisti...

Ultra high molecular weight polyethylene (UHMWPE) fibers are the third generation of high-performance fibers after carbon fibers and aramid fibers; It is currently the fiber with the highest specific strength and specific modulus among industrialized high-performance fibers, with excellent performance.

UHMWPE UD fabric sheet is a unidirectional construction in which the yarns are not woven but lie parallel to each other. UHMWPE UD fabric can be divided into soft sheet and hard sheet. Using UHMWPE UD fabric the minimum weight is needed for protection at different level, and it is not affected by water or sunlight and needs no special protection.

High Strength Reinforced Chopped Basalt Fiber

Basalt short cut fibers are fine fibers made from natural basalt through processes such as melting and drawing. Its raw materials are derived from volcanic rocks, which are thawed at high temperatures to form fibrous materials. Due to its unique mineral composition and structure, basalt short cut fibers have a certain strength and heat resistance, and are commonly used as base materials to enhance composite materials.

The production process of this short cut wire involves melting basalt at high temperatures, then pulling them into fine filaments through a spinneret, and finally cutting them into short cut wires of a certain length. Strictly control the process parameters during its production to ensure the uniformity and quality stability of the short cut fibers.

High Quality Chopped Basalt Fiber Strands For R...

Basalt fiber chopped strands are fine filamentous materials made by spinnings natural basalt after high-temperature melting. This short cut basalt fiber has high strength and heat resistance, and is usually used as a reinforcing material. During the production process, basalt is heated to an appropriate temperature to form a thawed state, and then extruded through a spinneret. After cooling, it solidifies into filaments. The length and diameter of short cut fibers can be adjusted according to the needs to meet the requirements of different industrial applications.

10mm Length Concrete Reinforcement Short Cut Ba...

Basalt short cut fibers are an inorganic fiber material formed by the high-temperature melting of natural basalt. Its manufacturing process involves melting basalt stone at high temperatures and then drawing it into fine filaments through technology. This material presents a short fiber like physical form and is suitable for various market demands.

The short cut basalt fiber produced has good uniformity and stability, which can meet the needs of different industrial fields. Due to its origin from natural materials and relative environmental friendliness, it has gradually gained market attention.