Customized Basalt Fiber Chopped Strands For Bui...

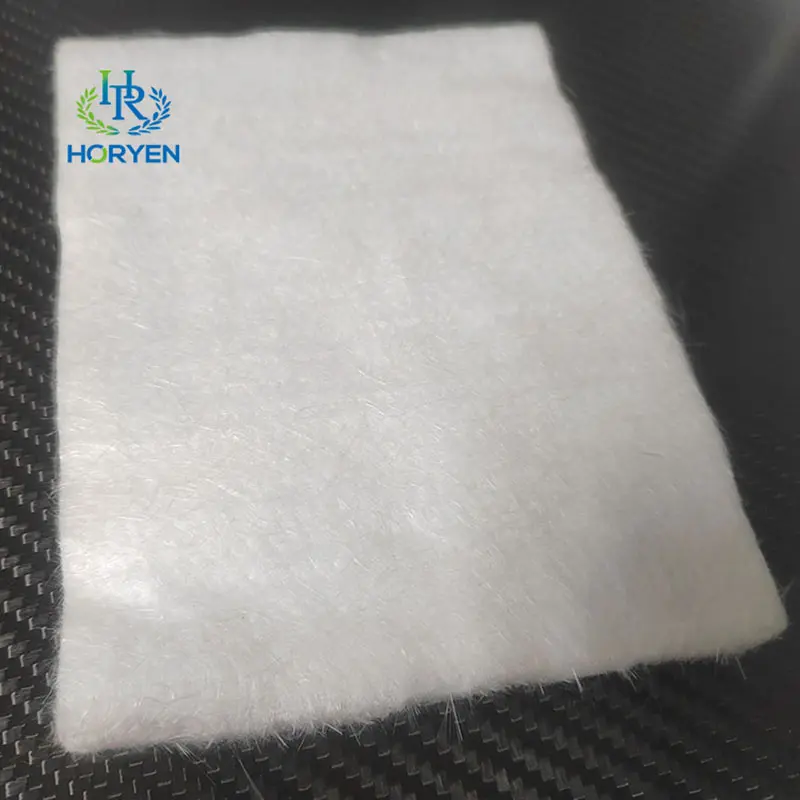

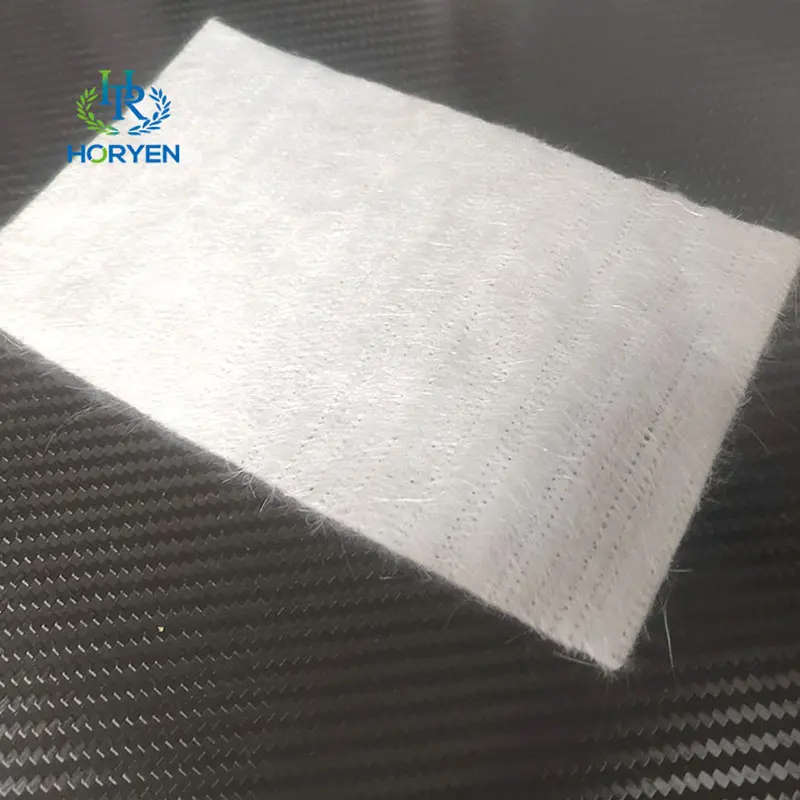

Basalt fiber chopped strands are short fiber materials made from natural basalt through specific processing techniques. The production process usually involves melting basalt ore at high temperatures and then drawing it into fibers through spinning technology. These short cut fibers have high strength and excellent high temperature resistance, and are widely used in various fields such as composite materials.

The main source of this material is volcanic rock, so its composition and structure are relatively stable, and it has good corrosion resistance and chemical resistance. Short cut silk can be cut to different lengths according to specific process requirements and application scenarios. Due to its excellent physical and chemical properties, basalt fiber chopped strands are gradually favored in modern industry and have become an important reinforcing material.

High Tensile Strength 6mm Length Short Cut Basa...

Basalt short cut fibers are slender fiber materials prepared by a specific process after natural basalt is melted at high temperatures. This material mainly heats basalt ore to high temperature and undergoes processes such as fiber drawing to form short cut fibers. These fibers have excellent physical properties and can function in various fields. The length of short cut basalt fiber usually ranges from a few millimeters to a few centimeters, which facilitates subsequent processing and application. Due to its origin from natural minerals, it has certain environmental characteristics.

High Strength Basalt Fiber Chopped Strand Concr...

Basalt fiber chopped strands are short fiber materials made by natural basalt after high-temperature melting. During its production process, basalt ore undergoes processes such as crushing, screening, and melting to ultimately form short cut fibrous products. Basalt fiber chopped strand silk usually ranges in length from a few millimeters to tens of millimeters, with a certain degree of uniformity and stability.

The manufacturing process of short cut basalt fibers is more environmentally friendly compared to other fiber materials because it is derived from natural ores and does not involve chemical synthesis processes. This has attracted attention in certain fields that require environmental protection. In terms of physical properties of the product, basalt short cut fiber exhibits excellent high-temperature resistance, corrosion resistance, and other characteristics, making it a preferred material under certain specific conditions.

High Quality 10mm Length Chopped Basalt Fiber S...

Basalt fiber chopped strands are short fiber materials formed by the high-temperature melting and fiberization treatment of natural basalt. This material is usually processed through specific techniques to pull melted basalt into small fibers, which are then cut into specific lengths of short fibers according to demand.

The manufacturing process of short cut basalt involves high-temperature treatment and physical processing of the material, aiming to preserve the natural characteristics of basalt while enhancing its application potential in engineering and construction fields. This material may involve some physical and chemical transformations in daily production processes, but it basically maintains the original structural characteristics of basalt.

Customized Concrete Reinforcement Basalt Fiber ...

Basalt fiber chopped strands are coated with special surface treatment agents to firmly bond with asphalt concrete. Basalt fiber chopped strands can significantly improve the high-temperature stability, low-temperature crack resistance, water damage resistance, and fatigue resistance of asphalt concrete, thereby greatly increasing the service life of asphalt concrete.

Basalt fiber chopped strands are usually coated with a sizing/binder to make them compatible with other materials and elements which it has to co-exists the primaryend product,this product is recommended to use for making non-woven mats,chopped strands mat,veils,brake,linings,clutch,plstes and for reinforcement of concrete and asphalt highway.It is a good choice to take place of other costly fiber and steel fiber.

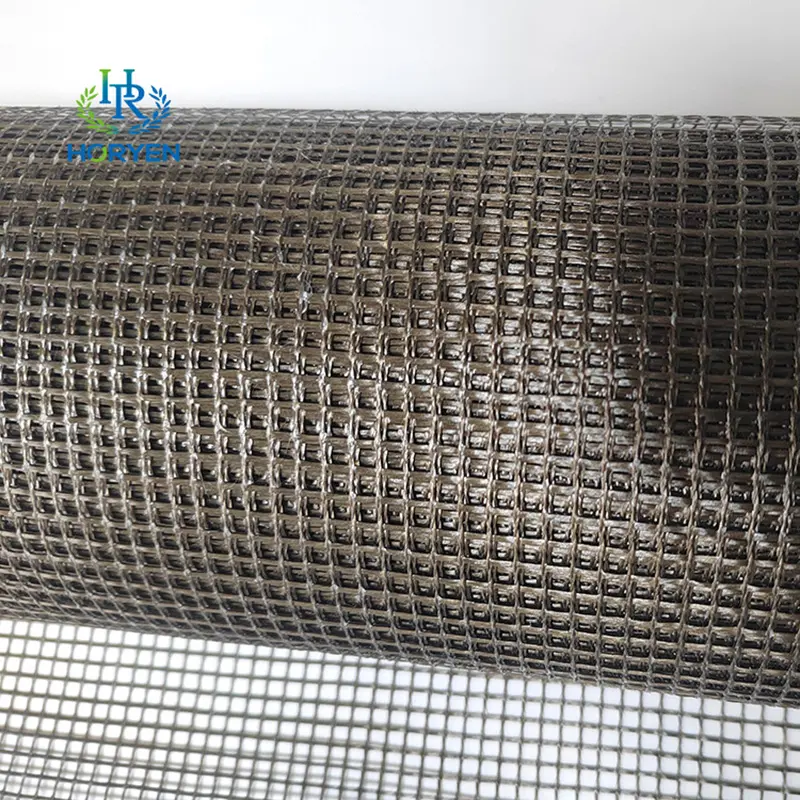

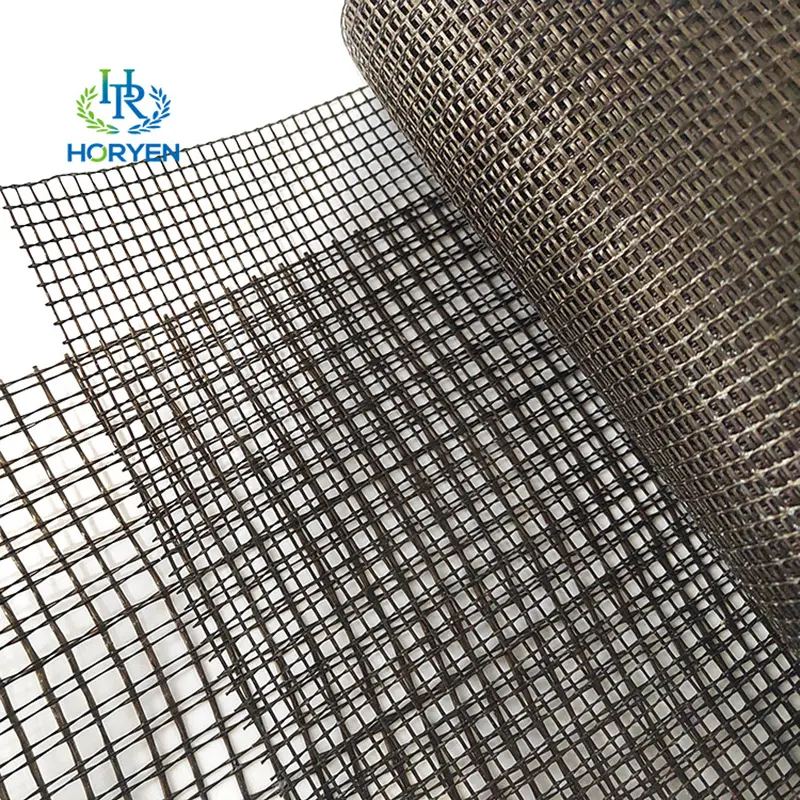

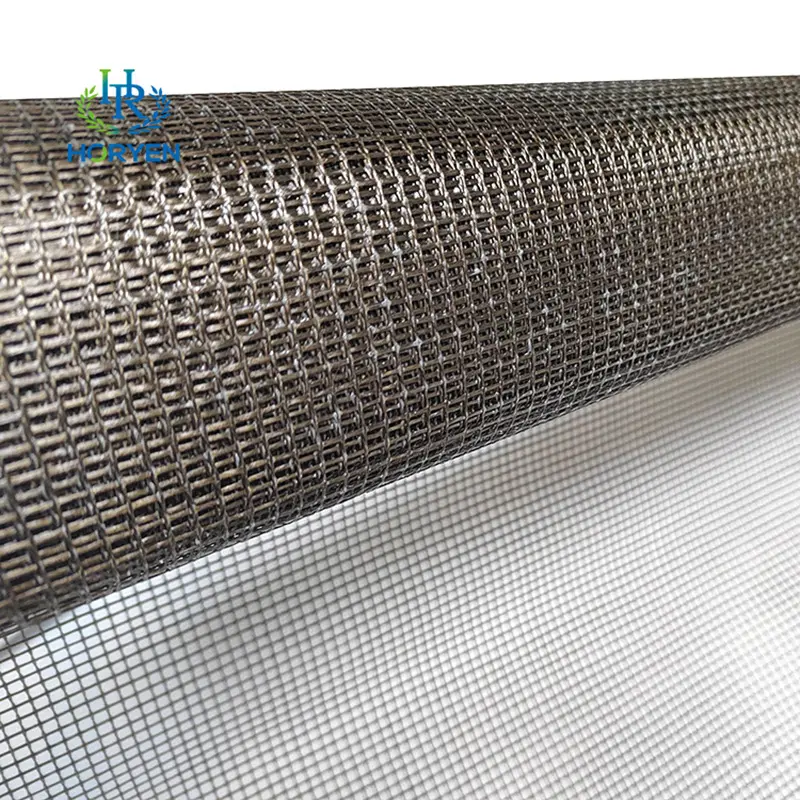

High Quality Reinforce Basalt Fiber Mesh Material

Basalt fiber mesh is a composite structure based on basalt materials, typically composed of a series of interlaced network fibers. The production process of this material involves melting basalt to form fibers, which are then woven into a grid like structure through specific techniques. Basalt fiber mesh has good physical and chemical stability, high temperature resistance, corrosion resistance and other characteristics, making it superior to many traditional materials in terms of performance. The design of its structure can provide excellent mechanical support and reinforcement effects, and is widely used in construction, civil engineering, and other related industries. Through its unique fiber arrangement, basalt fiber mesh can maintain its structural integrity and stability under different environmental conditions.

Hot Sale BFRP Geogrid Basalt Fiber Road Constru...

Basalt fiber mesh is a product made of basalt fibers, commonly used to enhance the strength and stability of various substrates. It forms a material with excellent tensile strength and high temperature resistance by weaving basalt fibers into a mesh structure.

The manufacturing process of this material involves heating basalt ore to high temperatures, melting it and pulling it into fibers, which are then processed into a grid like patterns. This grid can be adjusted according to different needs and specifications to adapt to various engineering and construction projects. Overall, basalt fiber mesh has become an important composite material foundations product due to its unique production process and material characteristics.

High Strength Basalt Fiber Mesh For Constructio...

Basalt fiber mesh is a composite material made of natural basalt fibers, usually presenting a grid like structure. It forms a material with high strength and durability by weaving or interlacing basalt fibers together. The process of making basalt fiber mesh usually involves melting basalt ore at high temperatures, then drawing it into slender fibers, and finally producing grid like products.

This mesh structure not only has good mechanical properties, but also enhances the stability and integrity of the material through its special fiber arrangement, providing a good foundation for subsequent processing and application. Due to its material properties, basalt fiber mesh has attracted attention in many fields and its potential in engineering and construction is evident to all.

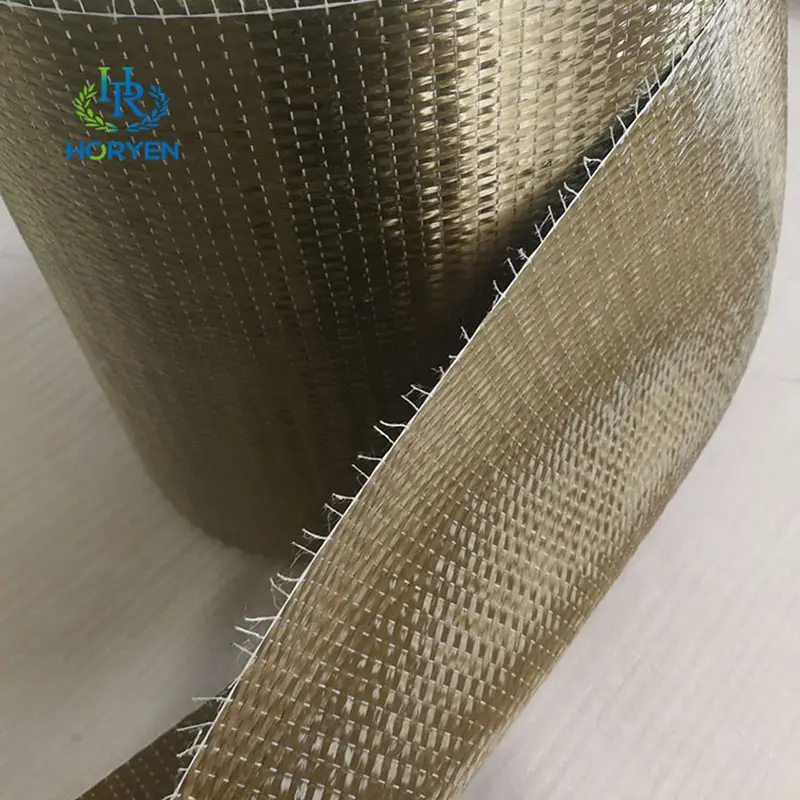

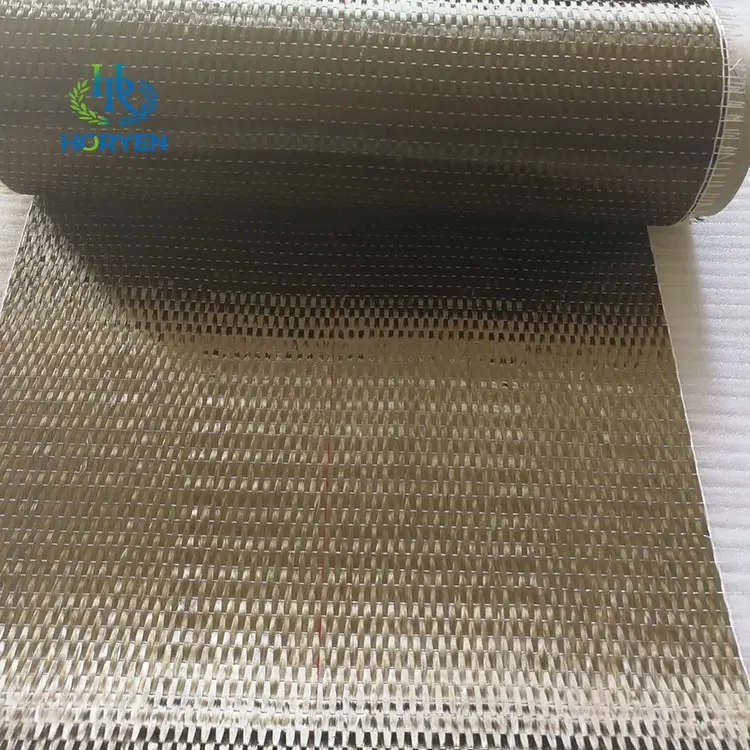

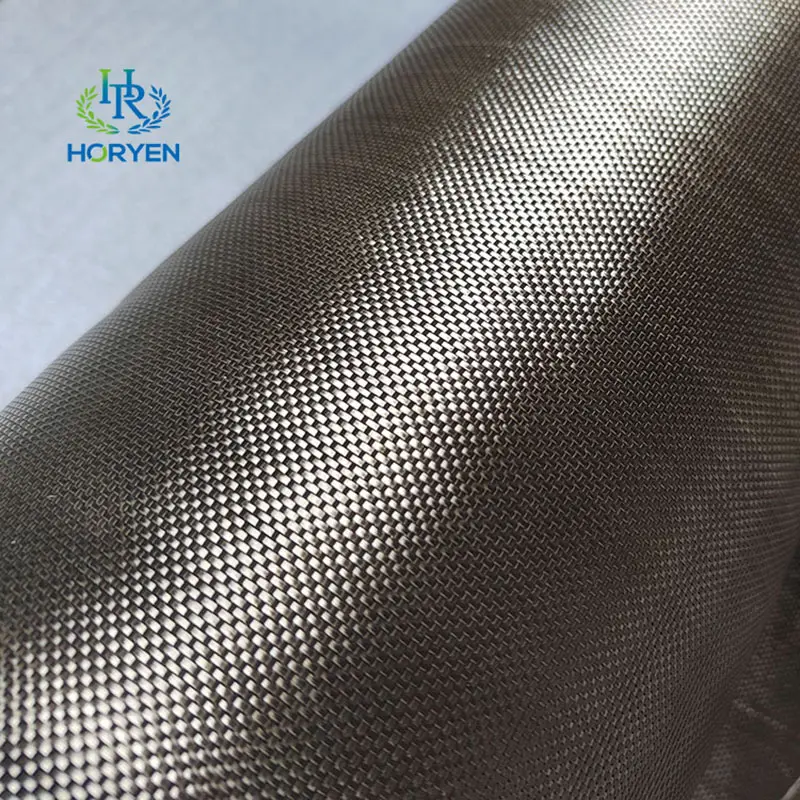

Hot Selling Unidirectional Basalt Fiber Fabric ...

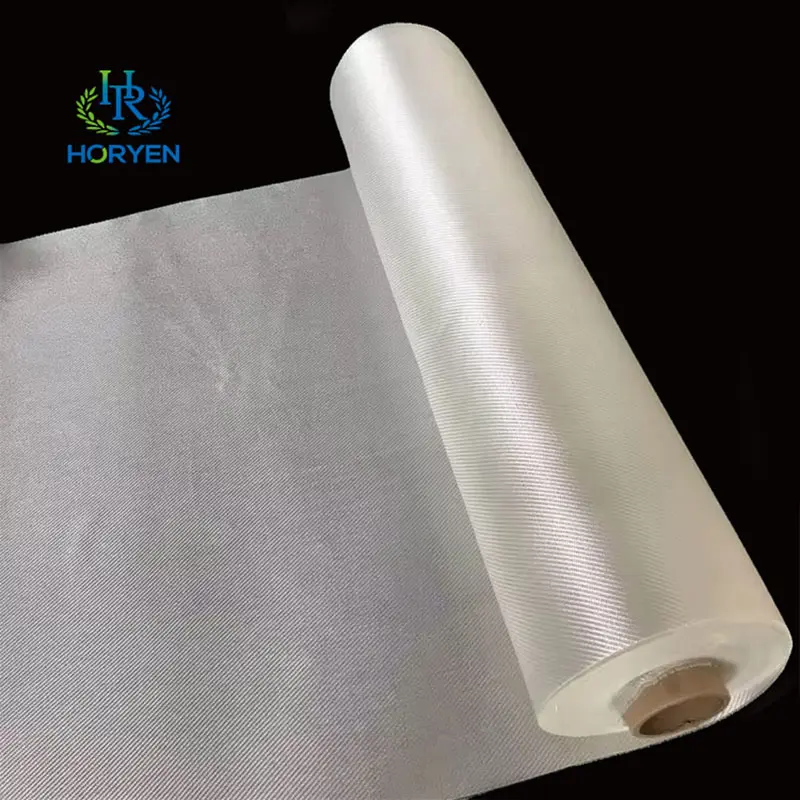

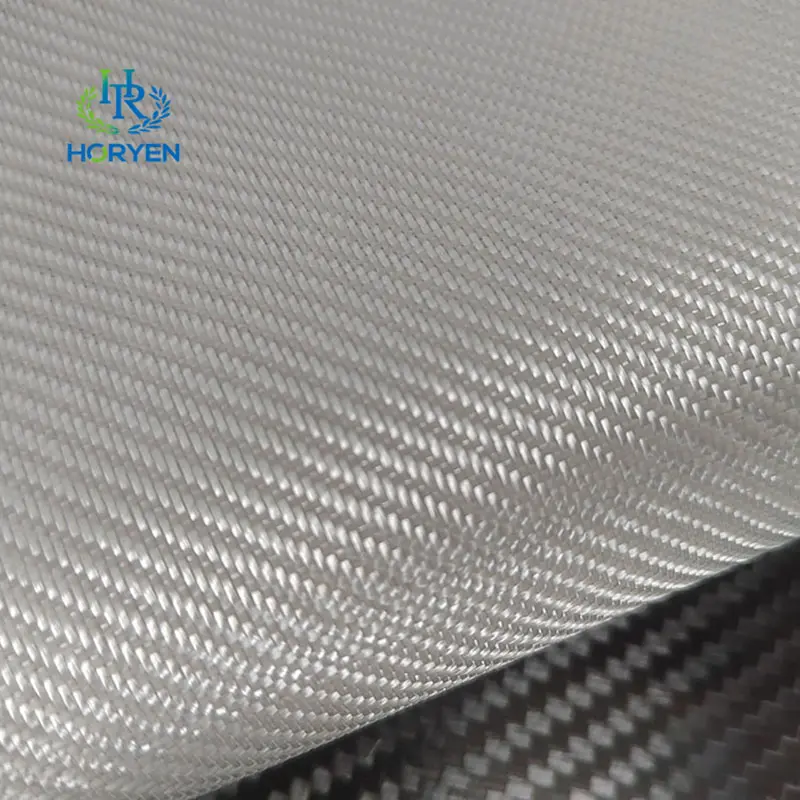

Unidirectional basalt fiber fabric is a composite material made of basalt fibers, usually made by arranging basalt fibers in a unidirectional manner. During its manufacturing process, basalt fibers undergo high-temperature melting and stretching to form high-strength fibers. These fibers are then arranged and solidified in a unidirectional manner to form a fiber cloth with a certain thickness and density. Its structural characteristics determine its special performance in mechanical properties, temperature resistance, and corrosion resistance, making it suitable for various industrial fields.

Reinforced Concrete High Quality UD Basalt Fibe...

UD basalt fiber fabric is a composite material woven from basalt fibers, usually made by unidirectional weaving. The production process involves melting basalt ore at high temperatures and then drawing it into fibers, which are arranged in a unidirectional manner to form a unified structure in the fabric.

The main structural feature of this fabric is that the fibers are arranged in one direction, forming a high-strength and high stiffness material. This arrangement gives the material excellent mechanical properties in that direction, while its performance is relatively weak in other directions. Due to its unique physical and chemical properties, UD basalt fiber cloth is widely used in fields such as engineering, construction, and materials science.

High Tensile UD Basalt Fiber Fabric for Buildin...

Basalt fiber UD fabric is an engineering material woven from high-performance basalt fibers. Uniformly apply a wetting agent suitable for phenolic and epoxy resins on the monofilament, which is suitable for the performance requirements of polyester, epoxy, phenolic, nylon and other resins. And coupling agents that match various resins are added to the impregnating agent to fully utilize the reinforcing effect of basalt fiber unidirectional fabric. Basalt fiber belongs to the typical silicate fiber series and has a thermal expansion coefficient similar to cement. It has good surface bonding properties with resins. Therefore, basalt fiber UD cloth is used for building, bridge reinforcement and repair. In some aspects,UD basalt fiber cloth has more outstanding comprehensive performance and cost-effectiveness than carbon fiber unidirectional cloth.

High Tensile Fireproof Basalt Fiber Fabric Conc...

Basalt fiber cloth is an inorganic high-performance fabric made from continuous fibers formed by high-temperature melting and drawing of natural basalt ore. It is produced through textile technology. Its core characteristics stem from the unique volcanic rock nature and molecular structure of basalt fibers, manifested as a deep integration of extreme environmental adaptability, excellent mechanical properties, multifunctional chemical stability, and ecological sustainability.