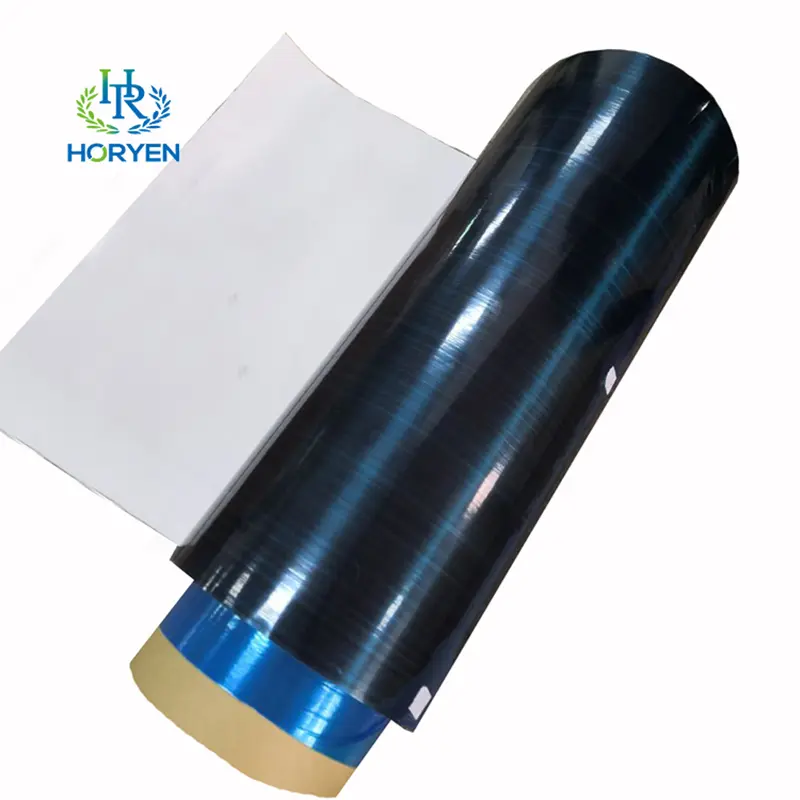

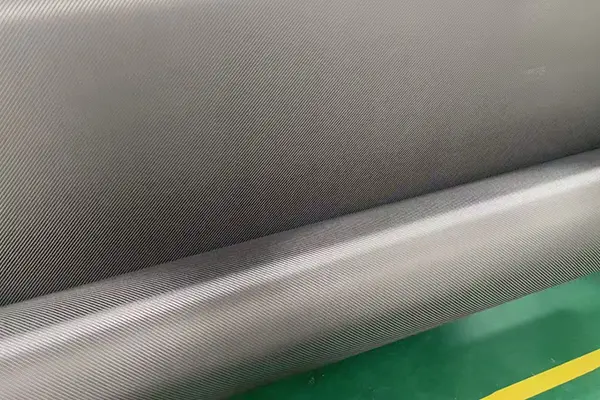

T700 Epoxy Resin UD Prepreg Carbon Fiber Cloth

Product Feature

High strength: UD carbon fiber prepreg cloth has very high tensile strength and stiffness in the fiber direction.

Lightweight: Compared to traditional materials, carbon fiber has a lower density, so the weight of prepreg is very light, which helps reduce the overall weight of the structure.

Excellent fatigue performance: UD prepreg carbon fiber fabric materials exhibit good fatigue resistance under repeated stress.

Chemical stability: Carbon fiber has excellent corrosion resistance and high temperature resistance, making it suitable for harsh environmental conditions.

Orientation: The fibers of UD fabric are arranged in a specific direction, resulting in optimal mechanical properties in that direction, while other directions are relatively weaker. This feature can be designed and optimized according to actual needs.

Excellent thermal conductivity: Carbon fiber has good thermal conductivity and is suitable for high-temperature applications.

|

Product Information |

|

|

Product Type |

UD Prepreg Carbon Fiber Fabric |

|

Material |

Carbon fiber fabric and epoxy resin |

|

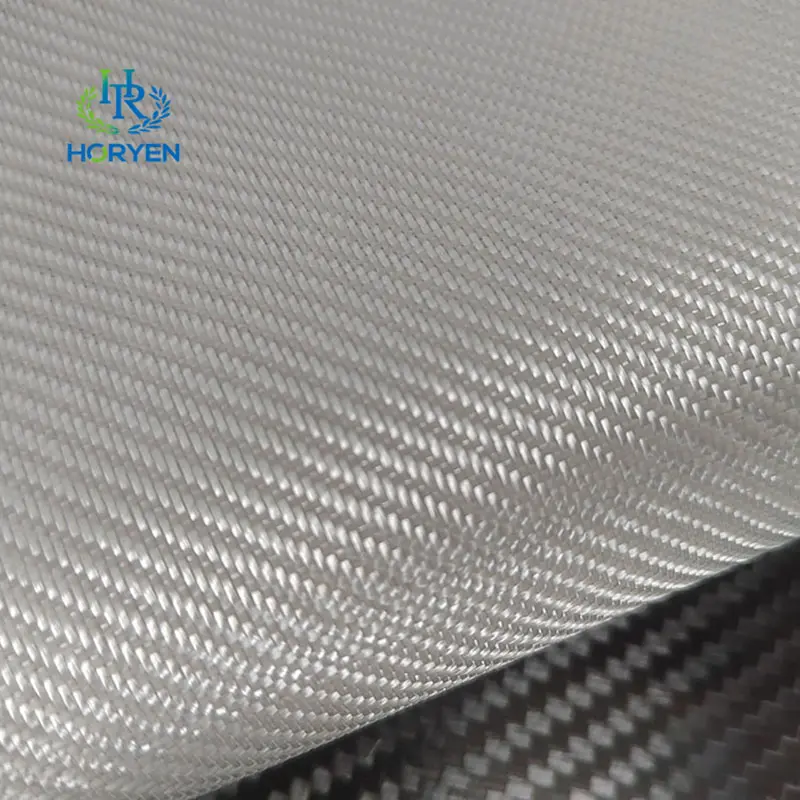

Weave style |

UD |

|

FAW |

Customized |

|

Thickness |

Customized |

|

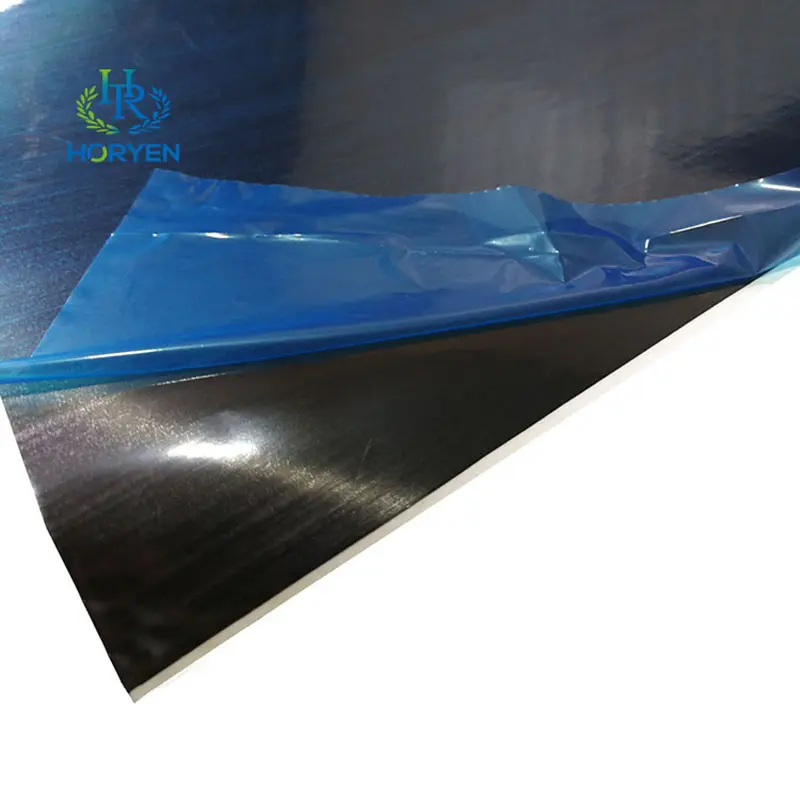

Color |

Black |

|

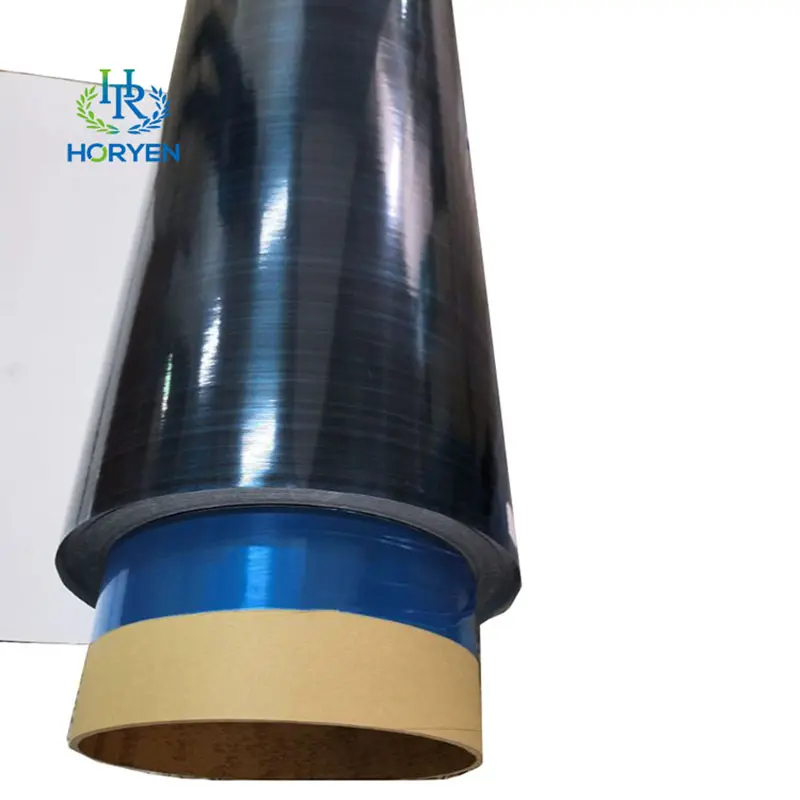

Width |

100cm |

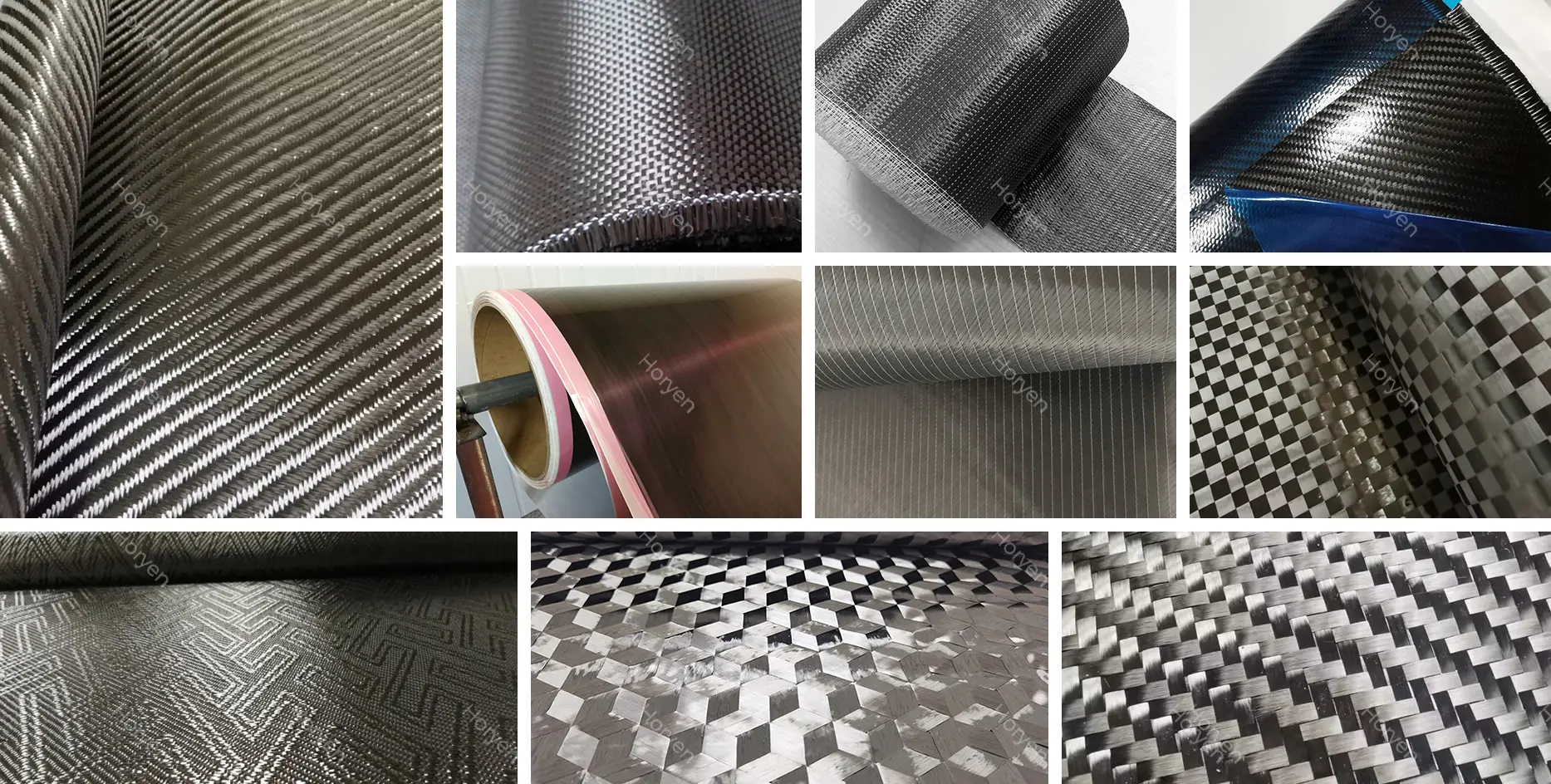

More Choice

Application Field

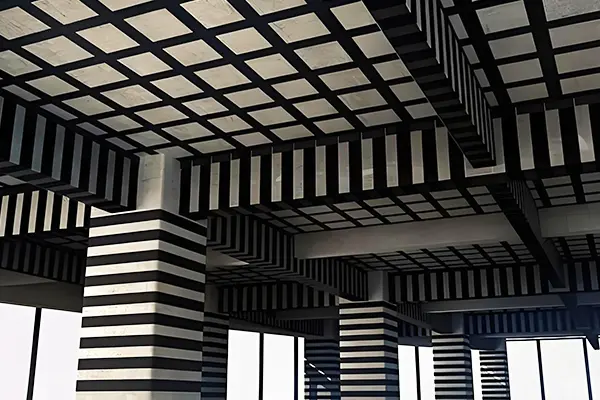

● Aerospace: Used for aircraft structural components, satellite parts, etc. to reduce weight and improve performance.

● Automotive industry: Lightweight design for high-performance racing cars and electric vehicles.

● Sports equipment: such as high-end bicycle frames, tennis rackets, skis, etc., to enhance strength and handling performance.

● Wind energy equipment: used for wind turbines blades, etc., to improve power generation efficiency.

Preparation Process

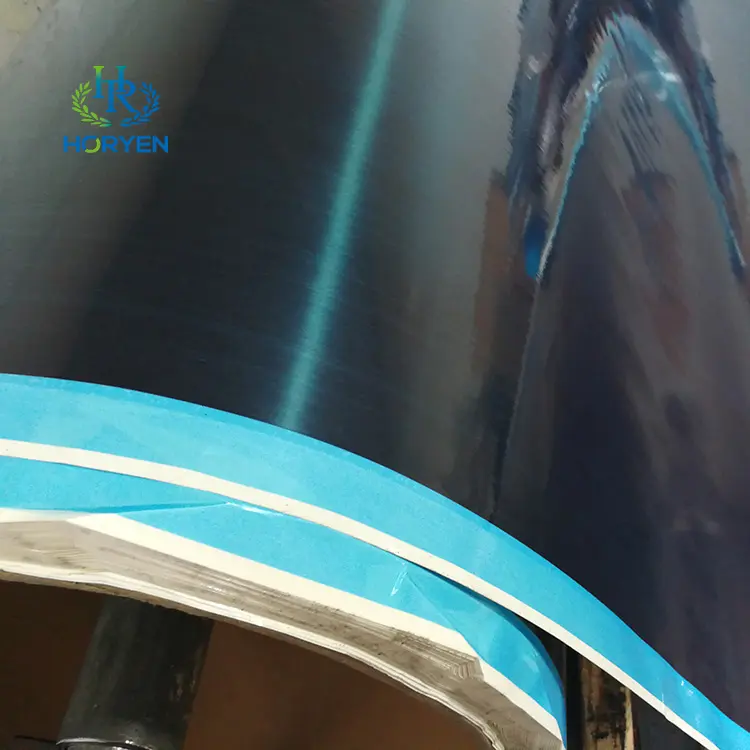

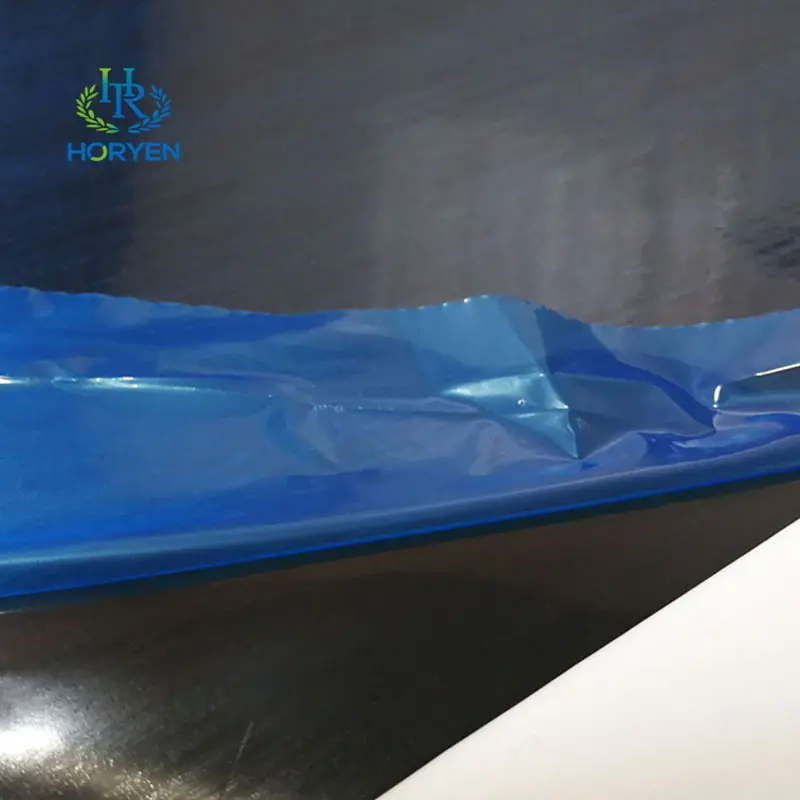

The preparation process of UD carbon fiber prepreg fabric mainly includes steps such as coating, hot pressing, cooling, coating, and winding. Firstly, carbon fiber yarn is mixed with materials such as epoxy resin, and then the mixture is uniformly coated on release paper through coating process. Then, it is subjected to hot pressing and cooling treatment, and finally rolled into a prepreg. The entire process requires strict control of temperature and pressure to ensure the quality and performance of the prepreg.

Why Choose Us?

Buyer Review

Our Factory

Packing & Transportation

FAQ

Product Parameter

| Product Information | |||||

| Product Type | Carbon aramid Fiber Fabric | ||||

| Material | Carbon fiber and aramid fiber | ||||

| Fabric Type | Cloth | ||||

| Warp | 3k | ||||

| FAW | 200g/m2 | ||||

| Thickness | 0.25mm | ||||

| Color | Yellow | ||||

| Width | 100cm or customized | ||||