-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In the ever-evolving landscape of engineering solutions, pultruded carbon fiber rods have emerged as a game-changing material, lauded for their exceptional strength-to-weight ratio and versatility. Dr. Emily Carr, a leading expert in advanced composite materials, emphasizes the significance of this innovation, stating, "The use of pultruded carbon fiber rods in engineering not only enhances structural integrity but also opens up new possibilities for design and performance."

As industries strive for efficiency and sustainability, the benefits of incorporating pultruded carbon fiber rods are becoming increasingly clear. Their lightweight nature reduces the overall weight of structures, thereby improving energy efficiency and performance. Furthermore, their resistance to corrosion and fatigue ensures longevity in demanding applications, making them an intelligent choice for engineers across various fields.

With an array of advantages such as improved strength, reduced maintenance costs, and enhanced aesthetic possibilities, the adoption of pultruded carbon fiber rods presents a forward-thinking approach to modern engineering challenges. This article delves into the top ten benefits of utilizing pultruded carbon fiber rods, highlighting why they are indispensable in today's engineering solutions.

Pultruded carbon fiber rods are revolutionizing engineering solutions due to their exceptional strength-to-weight ratio and durability. These rods exhibit a tensile strength of approximately 600,000 psi, making them nearly five times stronger than steel while being significantly lighter. This unique property allows engineers to design structures that are not only robust but also more cost-effective when considering transportation and installation. Additionally, carbon fiber's resistance to corrosion and fatigue enhances the longevity of components, reducing the need for frequent replacements and maintenance, which can save companies substantial costs over time.

One key benefit of pultruded carbon fiber rods is their versatility in application. From aerospace to automotive engineering, these rods can be tailored to meet specific requirements, allowing for innovations in design and functionality. According to a recent industry report, the global carbon fiber market is expected to reach USD 6.3 billion by 2026, reflecting the increasing demand for lightweight, strong materials in engineering applications. This growth underscores the importance of incorporating pultruded carbon fiber rods into modern engineering practices.

**Tips:** When considering materials for your next project, evaluate the specific load-bearing requirements alongside environmental conditions. Additionally, always consult with experts in material science to ensure you are choosing the best solution for your needs. Engaging in thorough research will help you leverage the full potential of pultruded carbon fiber rods in your engineering solutions.

| Benefit | Description |

|---|---|

| High Strength-to-Weight Ratio | Pultruded carbon fiber rods offer exceptional strength while remaining lightweight, making them ideal for applications requiring structural integrity without added weight. |

| Corrosion Resistance | Unlike metal rods, carbon fiber rods do not rust or corrode, providing longevity in harsh environments. |

| Thermal Stability | Carbon fiber rods maintain their shape and performance even at extreme temperatures, making them suitable for varied engineering applications. |

| Electrical Conductivity | Certain types of pultruded carbon fiber can be engineered to conduct electricity, useful in applications where grounded components are needed. |

| Fatigue Resistance | Carbon fiber rods are less prone to fatigue failures, ensuring reliability in repetitive load applications. |

| Customizable Designs | The pultrusion process allows for the creation of rods in multiple shapes and sizes, catering to specific engineering requirements. |

| Reduced Maintenance Costs | The durability and resistance to environmental factors means fewer replacements and repairs, lowering overall costs. |

| Aesthetic Appeal | Carbon fiber’s unique surface finish and modern look can enhance the visual appeal of various products and structures. |

| Sustainability | Carbon fiber production techniques are improving, with a focus on sustainable practices and reduced environmental impact. |

| Versatility | Suitable for a wide range of applications, including construction, aerospace, and automotive industries. |

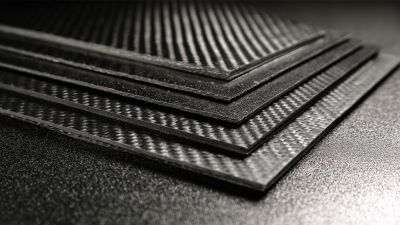

The enhanced strength-to-weight ratio of pultruded carbon fiber rods makes them a game-changer in various engineering applications. These rods are constructed using a process that aligns the carbon fibers in a unidirectional manner, which maximizes their tensile strength while keeping the weight astonishingly low. This unique property allows engineers to design structures and components that are not only robust but also significantly lighter than those made from traditional materials such as steel or aluminum. Consequently, the use of carbon fiber rods results in improved efficiency and performance in engineering applications, ranging from aerospace to automotive and civil engineering.

In applications where weight savings are critical, such as in aerospace engineering, the lightweight nature of pultruded carbon fiber rods enables the creation of more fuel-efficient aircraft. By reducing the overall weight of the structure, engineers can achieve better fuel economy and enhanced payload capacities. Similarly, in the field of civil engineering, these rods contribute to the construction of buildings and bridges that require less material while maintaining structural integrity. This not only leads to cost savings but also reduces the environmental impact of construction activities, making pultruded carbon fiber rods an ideal choice for sustainable engineering solutions.

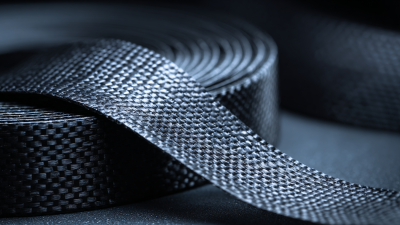

Pultruded carbon fiber rods have emerged as a game-changing material in engineering solutions, particularly due to their remarkable corrosion resistance. Unlike traditional materials such as steel or aluminum, carbon fiber rods do not corrode when exposed to moisture, chemicals, or extreme weather conditions. This characteristic significantly extends their lifespan, making them ideal for applications in harsh environments, such as marine structures, chemical processing plants, and infrastructure exposed to de-icing salts. As a result, engineers can design structures with confidence, knowing that the materials used will maintain their integrity over time without the need for frequent maintenance or replacement.

In addition to their corrosion resistance, the longevity of pultruded carbon fiber rods is a critical factor for long-term engineering projects. These rods maintain their strength and rigidity without succumbing to environmental degradation, ensuring that structures remain durable and functional for years. This aspect not only enhances safety but also reduces lifecycle costs associated with repairs and replacements. Consequently, the integration of carbon fiber rods into engineering designs not only improves performance but also contributes to sustainable building practices by minimizing material waste and maximizing resource efficiency.

This chart illustrates the top 10 benefits of pultruded carbon fiber rods, emphasizing their superior properties in engineering solutions. The data highlights key performance metrics such as corrosion resistance, weight reduction, tensile strength, and longevity, showcasing carbon fiber's advantages over traditional materials.

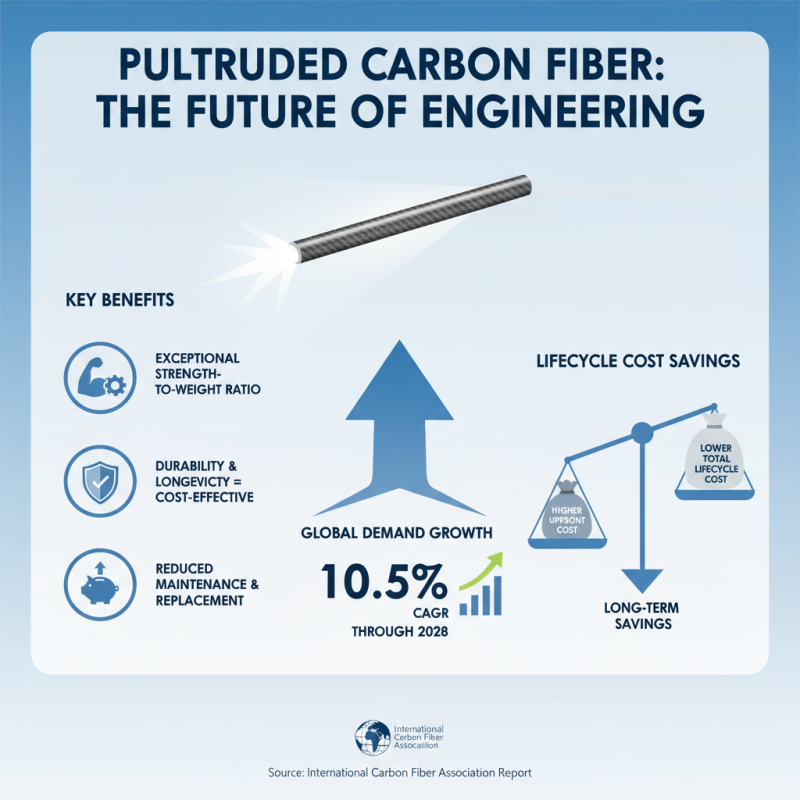

Pultruded carbon fiber rods have gained significant attention in engineering due to their exceptional strength-to-weight ratio and durability, leading to increasing cost-effectiveness in various applications. According to a report by the International Carbon Fiber Association, the demand for carbon fiber materials is projected to grow at a compound annual growth rate (CAGR) of 10.5% through 2028. This surge in demand is attributed to the long-term savings associated with pultruded products which, despite a higher upfront cost, offer reduced maintenance and replacement issues, translating into lower total lifecycle costs.

As engineering solutions continue to prioritize sustainability and efficiency, pultruded carbon fiber rods present compelling advantages. The advanced manufacturing process ensures minimal waste, while the material's inherent resistance to corrosion and environmental extremes reduces the need for frequent refurbishments. A study published in the Journal of Composites Technology indicates that using carbon fiber components can yield savings of up to 40% in maintenance costs over a structure's lifespan, making them an economically sound choice for long-term projects. This positioning not only elucidates their value in specialized engineering but illustrates a broader industry shift towards sustainable materials that reduce both financial and ecological footprints.

The versatility of pultruded carbon fiber rods in various engineering fields is remarkable, making them indispensable in many applications. From aerospace to civil engineering, these rods offer outstanding strength-to-weight ratios and excellent chemical resistance. Engineers are increasingly turning to carbon fiber rods for solutions requiring lightweight materials that do not compromise structural integrity. In construction, for example, the use of carbon fiber rods can enhance the durability of structures while reducing overall weight, leading to innovative design possibilities.

When exploring the use of pultruded carbon fiber rods, it’s important to consider their adaptability. They can be easily molded into different shapes and sizes, which allows them to fit specific requirements of diverse engineering projects. Additionally, carbon fiber’s innate resistance to corrosion makes it suitable for underwater and chemically exposed environments, ensuring longevity and reduced maintenance costs.

Tips: Always assess the mechanical properties required for your specific application when choosing carbon fiber rods. Properly understanding load-bearing capacities and environmental conditions will enhance the performance of your engineering solutions. Also, consider the advantages of combining carbon fiber rods with traditional materials to achieve optimal results in complex designs.