-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

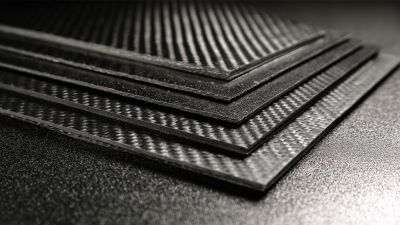

In the realm of engineering and materials science, the selection of the appropriate components can significantly impact the success and efficiency of projects. Among these components, the Pultruded Carbon Fiber Rod has emerged as a critical material due to its unique properties, such as high strength-to-weight ratio and excellent resistance to environmental factors. According to a report by MarketsandMarkets, the carbon fiber market is projected to reach $9.3 billion by 2025, driven by a surge in demand for lightweight and durable materials across various industries, including aerospace and automotive. The increasing adoption of pultrusion technology in manufacturing these rods further enhances their appeal, allowing for cost-effective production and precise dimensional accuracy. Consequently, understanding how to choose the best Pultruded Carbon Fiber Rod for your engineering projects is essential for optimizing performance and achieving desired outcomes.

When selecting pultruded carbon fiber rods for engineering applications, several critical factors must be considered to ensure optimal performance and cost-effectiveness. First, assess the mechanical properties required for your specific project, such as tensile strength, flexural rigidity, and impact resistance. Different carbon fiber compositions provide varying performance characteristics; therefore, understanding the load and stress your application will encounter is essential in making an informed choice.

When choosing the best pultruded carbon fiber rod for engineering projects, understanding the mechanical properties of carbon fiber is crucial for ensuring structural integrity. Recent studies have highlighted the multifaceted performance of carbon fiber composites (CFCs), demonstrating their exceptional mechanical strength, stiffness, and lightweight characteristics, which are essential for applications ranging from aerospace to civil engineering. For instance, research indicates that carbon fiber reinforced polymer (CFRP) can maintain retention strength even under elevated temperatures, making it a reliable choice for demanding environments.

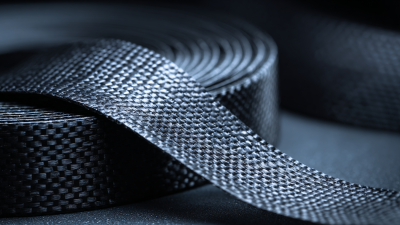

Moreover, the latest advancements in additive manufacturing techniques have opened new avenues for enhancing the mechanical properties of carbon fiber composites. Techniques such as Fused Filament Fabrication (FFF) have been shown to optimize the microstructure of CFRP materials, leading to substantial improvements in performance metrics, such as fracture toughness and resistance to mechanical loads. A comprehensive analysis suggests that the incorporation of controlled gamma irradiation can also enhance the water resistance and durability of fiber-reinforced composites, thereby expanding their applicability in various engineering domains. Understanding these mechanical properties will enable engineers to select the most suitable pultruded carbon fiber rods tailored to the specific demands of their projects.

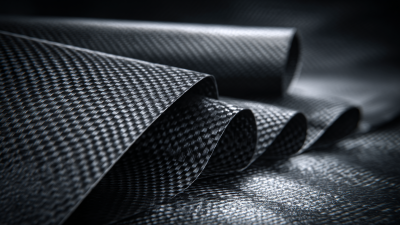

When selecting a pultruded carbon fiber rod for engineering projects, understanding the relationship between density, weight, and strength is crucial. Density refers to the mass per unit volume of the material and plays a significant role in how a rod performs under various loads. In general, higher density carbon fiber rods tend to offer increased strength and stiffness, making them suitable for demanding applications where durability is paramount. However, this larger mass can also impact the overall weight of the project, which is a critical factor in design considerations, especially in fields like aerospace or automotive engineering.

On the other hand, lower density options present benefits in terms of weight reduction, allowing for lighter structures without sacrificing much strength. This can be particularly advantageous in scenarios where weight savings are crucial. Engineers must carefully evaluate the specific performance requirements of their projects, analyzing how different densities alter performance characteristics. Striking the right balance between weight and strength will ultimately lead to the most efficient and effective use of pultruded carbon fiber rods in engineering applications.

When selecting pultruded carbon fiber rods for engineering projects, understanding design specifications such as sizing and tolerance guidelines is crucial. The size of the rod, typically determined by its diameter and length, greatly influences both its structural integrity and application suitability. Engineers must consider the dimensions that best fit their specific needs while ensuring that the rods can withstand the mechanical loads they are expected to bear. Tolerances in size indicate the permissible limits of variation in dimensions, which can affect the compatibility with other components in an assembly.

Additionally, the tolerance levels specified by the manufacturer ensure that the rods maintain expected performance characteristics during use. For instance, tighter tolerances might be necessary in high-precision applications, while broader tolerances could suffice in less critical environments. By meticulously assessing these parameters, engineers can select the right pultruded carbon fiber rods that not only align with their project requirements but also enhance the overall reliability and functionality of their designs.

When selecting pultruded carbon fiber rods for engineering projects, cost is a pivotal factor that influences performance and suitability. According to a recent report by the Composite Materials Handbook, the average cost of pultruded carbon fiber rods ranges from $20 to $50 per kilogram, depending on the quality and manufacturing processes involved. Lower-cost options may compromise strength and durability, which can lead to higher expenses down the line due to maintenance or replacement needs.

Balancing budget with performance requires careful consideration of the specific application and the required mechanical properties. For instance, a high-strength rod suitable for aerospace applications may justify a higher upfront cost due to its superior structural integrity under extreme conditions. It's crucial to conduct a cost-benefit analysis, comparing the long-term gains of investing in high-performance materials against the immediate savings of cheaper alternatives.

**Tips**: When evaluating options, consider the lifetime costs associated with your choice, including maintenance and potential downtime. Additionally, consult with suppliers about bulk purchasing discounts or material selection that aligns with your performance criteria. Lastly, leverage industry reports to ensure your choice meets established standards for safety and efficacy in your specific field.

| Diameter (mm) | Length (m) | Price ($) | Weight (kg) | Tensile Strength (MPa) |

|---|---|---|---|---|

| 6 | 1 | 20 | 0.2 | 600 |

| 8 | 1 | 25 | 0.3 | 700 |

| 10 | 1 | 30 | 0.4 | 800 |

| 12 | 1 | 35 | 0.5 | 900 |

| 15 | 1 | 40 | 0.6 | 1000 |