-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

Choosing the right Pultruded Carbon Fiber Bar for your engineering projects can significantly impact the overall performance and durability of your design. With a wide array of options available in the market, understanding the key characteristics and applications of different bars is essential for engineers and designers alike. Pultruded Carbon Fiber Bars are increasingly favored for their exceptional strength-to-weight ratio, corrosion resistance, and versatility in various fields, including aerospace, automotive, and civil engineering. This guide aims to provide you with essential insights into selecting the most suitable Pultruded Carbon Fiber Bar by exploring crucial factors such as material specifications, manufacturing processes, and application requirements. By making informed choices, you can ensure that your engineering projects achieve optimal performance, sustainability, and efficiency.

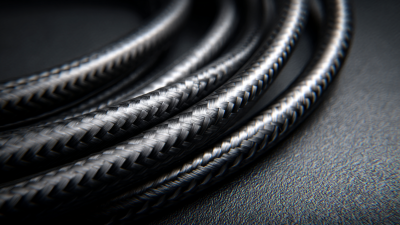

Pultruded carbon fiber bars are renowned for their unique properties that make them ideal for various engineering applications. These bars are created through a continuous process that combines high-strength carbon fibers with a thermosetting resin, producing a lightweight yet sturdy material. According to a recent industry report by MarketsandMarkets, the global market for carbon fiber composites is expected to reach $32 billion by 2026, primarily driven by their exceptional strength-to-weight ratio and resistance to corrosion. This makes them particularly suitable for use in aerospace, automotive, and civil engineering projects where performance and durability are crucial.

When selecting the right pultruded carbon fiber bar, it's essential to consider the specific mechanical properties required for your project. For instance, the tensile strength of these bars can exceed 700 MPa, while their modulus of elasticity can range from 70 to 150 GPa depending on the resin used. Tip 1: Always compare the mechanical specifications with the demands of your application to ensure optimal performance. Additionally, the unique fatigue resistance of carbon fiber makes it a preferred choice for structures subjected to repetitive loads.

Another crucial factor is the environmental conditions the bars will face. Pultruded carbon fiber exhibits excellent thermal stability, withstanding temperatures up to 200 degrees Celsius. Tip 2: Evaluate the thermal and chemical exposure your project may encounter, as this will guide your choice of resin and fiber configuration. By understanding these properties and selecting accordingly, you can harness the full potential of pultruded carbon fiber bars in your engineering endeavors.

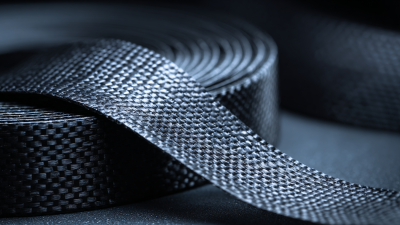

When selecting pultruded carbon fiber bars for engineering projects, there are several key factors to consider that can greatly influence performance and durability. First, understanding the mechanical properties of carbon fiber is crucial. According to a recent report by the Carbon Fiber Industry Association, carbon fiber is known for its high tensile strength, often exceeding 600 MPa, and a stiffness of around 230 GPa. These characteristics make it suitable for applications where lightweight materials are essential without compromising on strength.

Another important factor is the bar's dimensions and weight-to-strength ratio. A study published by Advanced Materials Research highlights that optimized sizing of carbon fiber bars can enhance their load-bearing capacity while minimizing excess weight. Engineers should also consider the environmental conditions the bars will be exposed to; the material's resistance to corrosion and temperature fluctuations is vital. Reports show that pultruded carbon fiber maintains integrity at temperatures up to 200°C, making it ideal for various engineering environments. By focusing on these considerations, engineers can make informed choices that align with the specific requirements of their projects.

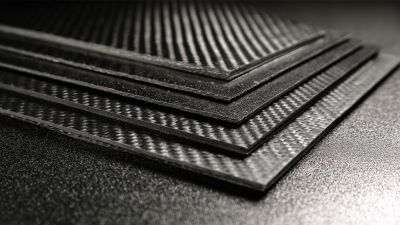

When selecting pultruded carbon fiber bars for engineering projects, evaluating their load capacity and structural integrity is crucial.

Load capacity refers to the maximum weight or force that a carbon fiber bar can safely support without bending or breaking. This can be influenced by various factors, including the bar's dimensions, the type of resin used, and the fiber orientation within the composite material. Engineers should consider using standardized testing methods to ascertain specific load limits, ensuring the chosen bar will withstand the conditions expected in the project.

In addition to load capacity, assessing the structural integrity of carbon fiber bars is vital. This assessment involves examining how well the bar maintains its shape and performance under stress, including fatigue resistance and impact performance.

Factors such as moisture absorption, temperature fluctuations, and exposure to chemicals can also affect structural integrity. By conducting thorough evaluations and selecting bars with proven durability in the intended environment, engineers can optimize their designs and ensure the longevity and safety of their projects.

When selecting pultruded carbon fiber bars for engineering projects, understanding the balance between cost and performance is crucial. Carbon fiber bars offer exceptional strength-to-weight ratios and high durability, making them an attractive choice for a range of applications. However, not all carbon fiber products are created equal, and prices can vary significantly based on material quality, manufacturing processes, and supplier reputation. It is important to assess how these factors align with your project's specific requirements and budget.

Tips: Before making a purchase, conduct a thorough market analysis. Compare the specifications of various products along with their prices, and be transparent about the intended use of the carbon fiber bars. This will help you determine the right type that meets your performance criteria without excessively impacting your budget. Additionally, consider exploring different suppliers and requesting samples to evaluate both the quality and the performance capabilities of the materials before committing to a larger order.

Moreover, don't overlook the long-term cost of ownership. High-quality carbon fiber bars may come with a higher upfront cost, but their longevity and reduced need for replacements can make them more economical in the long run. Ensure that you weigh the initial investment against the benefits of performance, reliability, and maintenance costs to select the most effective option for your engineering needs.

When selecting a pultruded carbon fiber bar for engineering projects, supplier credibility and quality assurance are crucial factors to consider. According to a recent market analysis published by Research and Markets, the global carbon fiber market is projected to reach $30.2 billion by 2025, highlighting the increasing demand and diversity in suppliers. As the industry grows, the potential for variability in product quality also escalates, making it imperative to choose suppliers with a proven track record. ISO certifications and compliance with ASTM standards are essential indicators of quality assurance that can help mitigate risks associated with inferior products.

Furthermore, it’s essential to vet the supplier's history in the market. Reports indicate that 70% of engineering firms emphasize the importance of long-term partnerships with reliable suppliers, as they often have established systems for quality control, including rigorous testing protocols and continuous monitoring of raw materials. Engaging with suppliers who offer clear documentation, such as test results and material data sheets, can provide invaluable insights and assurance regarding the product's performance in specific applications. Prioritizing these aspects can lead to more successful engineering outcomes and a robust supply chain.