-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

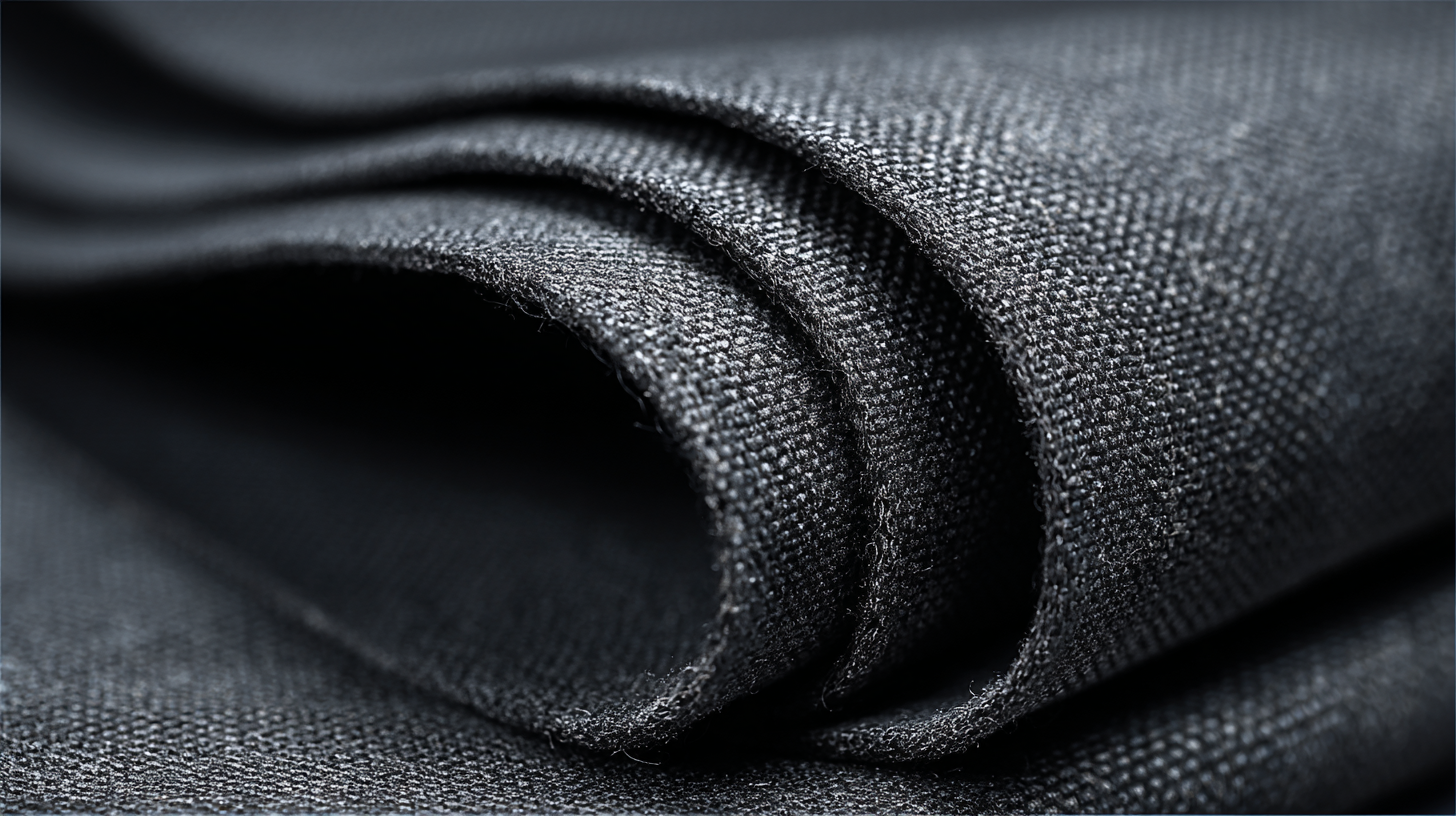

When it comes to ensuring personal safety in high-risk environments, the choice of materials used in protective gear cannot be underestimated. Stab resistant fabric, designed to withstand penetration from sharp objects, plays a crucial role in this domain. According to a report by the Textile Protection and Comfort Institute, the global market for stab resistant materials is projected to reach $11 billion by 2025, highlighting a significant demand for effective protective solutions. However, the efficacy of these fabrics greatly depends on their composition, weave, and certification standards. In this context, selecting the right stab resistant fabric can be daunting, and understanding key features is essential for maximizing safety. This article presents five essential tips that will aid in making informed decisions when choosing stab resistant fabric, ensuring optimal protection in vulnerable situations.

When selecting stab resistant fabrics, it's crucial to understand the various types available on the market. Materials like Kevlar, Dyneema, and other proprietary blends offer different levels of protection and flexibility. Kevlar, known for its durability, is commonly used in personal armor but may lack breathability. On the other hand, Dyneema boasts high strength-to-weight ratios and excellent moisture management, making it suitable for both protective clothing and outdoor gear.

Tip 1: Always consider the specific threat level and environment in which the fabric will be used. For example, if you're in a hot climate, opt for breathable materials that do not compromise safety.

Tip 2: Another factor to keep in mind is the fabric's weight. While heavier materials typically offer better protection, they can be cumbersome and limit movement. Assess the trade-off between weight and safety based on your needs.

Knowing the differences among these materials will help you make an informed decision and ensure maximum safety in potentially hazardous situations.

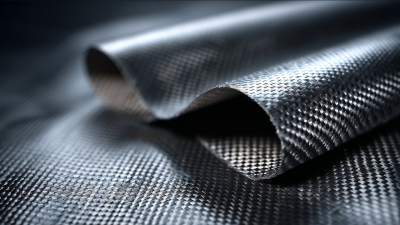

When selecting stab-resistant fabric, it's crucial to focus on key features that ensure maximum safety. The primary consideration should be the material's tensile strength, as this determines its ability to withstand penetrating forces. According to a report from the National Institute of Justice (NIJ), high-performance fibers such as aramid and ultra-high molecular weight polyethylene (UHMWPE) demonstrate superior resistance properties due to their molecular structure, which provides excellent energy dispersion upon impact.

Another important characteristic is puncture resistance. Fabrics that meet or exceed the standards set by the NIJ are often tested for their ability to resist various stabbing threats. For example, materials with a layering design, combining different types of fibers, can significantly improve protective performance. It's recommended to look for fabric that has been certified to NIJ’s stab resistance standards, ensuring the material has undergone rigorous testing.

Additionally, consider the weight and flexibility of the fabric. While heavier materials may offer greater protection, they can become cumbersome. Lightweight options, like those incorporating advanced composites, can provide necessary defense without sacrificing comfort. This balance is essential for ensuring that the fabric can be worn comfortably for extended periods while still offering robust protection against potential threats.

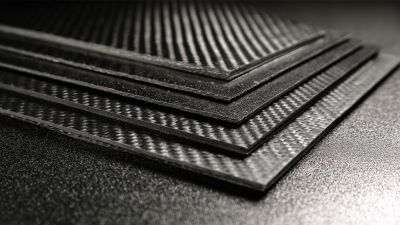

| Feature | Description | Importance |

|---|---|---|

| Material Type | Choose high-performance synthetic fibers such as Kevlar or Dyneema. | Provides superior strength and durability against stabbing. |

| Weight | Consider the weight to maintain comfort while ensuring adequate protection. | Lightweight fabric increases wearability and mobility. |

| Thickness | Opt for materials with balanced thickness for effective stab resistance. | Thicker fabrics generally offer more protection, but consider flexibility. |

| Testing Standards | Ensure the fabric meets recognized safety standards for stab resistance. | Compliance with standards ensures reliability and safety. |

| Comfort | Evaluate breathability and softness for all-day wearability. | High comfort levels encourage consistent use in dangerous environments. |

When selecting stab-resistant fabric, it is crucial to assess the level of stab resistance that aligns with your specific needs. Different environments and purposes may require varying degrees of protection. For example, if the fabric is intended for personal safety, such as in stab-resistant vests, understanding the potential threats and the force behind them is vital. Fabrics are tested according to stand standards like the NIJ (National Institute of Justice) levels, which categorize the resistance based on different threat levels. Knowing these classifications helps you choose the right fabric tailored to your circumstances.

Another aspect to consider is the weight and flexibility of the fabric. A balance between protection and comfort is essential; the fabric should not compromise mobility or everyday usability. Evaluate how the fabric performs under real-world conditions, including its resistance not just to stabbing but also to abrasion and cutting. Doing so ensures that you select a material that offers comprehensive protection while still being practical for daily activities. Always seek advice from manufacturers or experts who can provide information on the material's performance in specific environments, helping you make an informed selection for your safety needs.

When selecting stab-resistant fabrics, comfort and flexibility are crucial factors that cannot be overlooked. A fabric that provides maximum safety but lacks ease of movement can hinder the user’s performance and overall experience. The best stab-resistant materials are designed to disperse the energy of an attack while still allowing the wearer to move freely, which is essential in dynamic environments.

Moreover, advanced engineering has led to innovations in fabric technology that enhance both comfort and functionality. Features such as breathability, lightweight construction, and moisture-wicking properties elevate the user experience, making it possible to wear protective gear for extended periods without discomfort. Testing various fabrics under real-world conditions will provide insight into how they perform in terms of flexibility and user comfort, leading to informed decisions that prioritize safety without sacrificing everyday ease of use.

When selecting stab-resistant fabric, it's critical to prioritize the reliability of manufacturers and ensure that products come with recognized safety certifications. A reputable manufacturer not only adheres to industry standards but also invests in rigorous quality control processes to ensure that their fabrics can withstand tested threats effectively. Always look for certifications from respected organizations that audit and verify safety claims. These certifications serve as an additional layer of assurance that the fabric meets stipulated performance criteria.

Moreover, consider the manufacturers' sourcing and production practices. Companies committed to transparency often highlight where they source their materials and how they maintain safety throughout the production process. This commitment to quality not only supports the safety of their products but also reflects a culture of responsibility in their operations. By aligning with manufacturers that prioritize quality and safety, you can make more informed choices about stab-resistant fabrics that will ultimately provide maximum safety.

When exploring options, be sure to evaluate customer reviews and professional endorsements, as they can provide valuable insights into the performance of the fabric in real-world scenarios. Prioritizing these elements will ensure you choose a product that not only meets your safety needs but also stands the test of time.