-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In the world of composite materials, the "Pultruded Carbon Fiber Bar" stands out for its strength and versatility. Dr. Emily Zhang, an expert in advanced composites, once remarked, “The potential of pultruded carbon fiber is just beginning to be understood.” This statement captures the innovation within this field.

Pultruded carbon fiber bars are known for their remarkable properties. They offer both high tensile strength and low weight, making them ideal for various applications. Industries are exploring uses in construction, automotive, and aerospace sectors. The lightweight nature of these bars allows for energy savings and improved efficiency. Yet, challenges remain. Production costs can be high, and not all manufacturers achieve the same quality standards.

As we delve deeper into the benefits and applications of pultruded carbon fiber bars, it is essential to acknowledge these complexities. Understanding these materials requires recognition of their limitations and the ongoing need for innovation. The potential is immense, but the industry must navigate these hurdles to fully realize the advantages of pultruded carbon fiber technology.

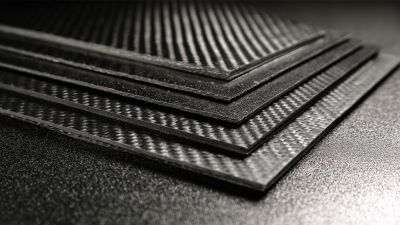

Pultruded carbon fiber bars are advanced composite materials. They are made through a method known as pultrusion. In this process, continuous carbon fibers are drawn through a resin and then shaped into a solid profile. This results in a strong, lightweight material. The properties of these bars make them ideal for various applications.

One of the main benefits of pultruded carbon fiber bars is their strength-to-weight ratio. They are much lighter than steel, yet offer similar or superior strength. This makes them useful in construction and automotive applications. Additionally, they have excellent corrosion resistance. Unlike metal, they do not rust, which prolongs their lifespan in many environments.

Tips: When considering pultruded carbon fiber bars, be mindful of their flexibility. While they are strong, excessive force can lead to breakage. Always evaluate the load they will carry. Understand the specific requirements of your project. They may not be budget-friendly for everyone. However, in high-performance scenarios, their advantages shine. Choose wisely to maximize benefits and avoid potential pitfalls.

| Dimension | Value | Benefit | Application |

|---|---|---|---|

| Length | Up to 30 ft | Customization | Construction |

| Weight | Lightweight | Reduced shipping costs | Aerospace |

| Tensile Strength | 300 ksi | High performance | Automotive |

| Corrosion Resistance | Excellent | Longevity | Marine |

| Thermal Conductivity | Low | Thermal insulation | Electronics |

Pultrusion is a continuous manufacturing process that creates strong carbon fiber bars. In this method, carbon fibers are immersed in a resin and then drawn through a heated die. The heat cures the resin, forming a solid and durable bar. This process allows for precise control over the bar's dimensions and properties.

The efficiency of pultrusion can lead to significant cost reductions. According to a recent industry report, pultruded materials can be up to 70% stronger and lighter than traditional materials. This advantage makes them ideal for various applications, including construction, automotive, and aerospace sectors. The high strength-to-weight ratio is appealing.

However, pultrusion is not without challenges. The process requires careful management of the resin cure time. Improper curing can lead to defects in the final product. Additionally, while the initial setup costs for pultrusion can be high, operating costs can be lower over time. Balancing these factors is crucial for manufacturers.

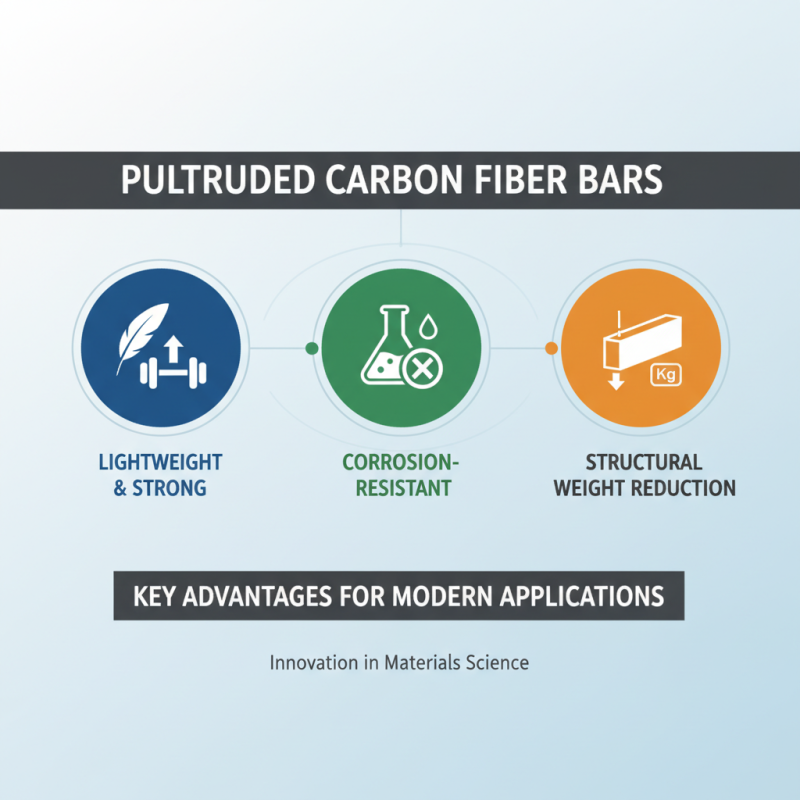

Pultruded carbon fiber bars have gained popularity due to their unique advantages. These bars are lightweight yet incredibly strong. They are resistant to corrosion, making them ideal for various environments. Their use can significantly reduce the weight of structures without sacrificing durability.

One key benefit is the flexibility in design. Pultruded bars can be manufactured in various shapes and sizes. This adaptability allows engineers to create custom solutions for specific applications. Also, the ability to withstand extreme temperatures adds to their appeal.

**Tip**: When selecting pultruded carbon fiber bars, consider their intended application. Ensure to assess the environmental factors they will face.

Another advantage is their long lifespan. Unlike traditional materials, these bars do not rot or degrade over time. This durability leads to lower maintenance costs in the long run. However, be aware that the initial investment can be higher.

**Tip**: Always compare the long-term costs and benefits of using pultruded carbon fiber versus other materials. This can help make a more informed decision.

In summary, pultruded carbon fiber bars combine strength and versatility. They stand out in various industries, from construction to automotive sectors. Their unique properties can be transformative for many projects, but careful consideration of costs and applications is essential.

Pultruded carbon fiber bars are versatile and widely used in various applications. Their high strength-to-weight ratio makes them ideal for construction, automotive, and aerospace industries. In construction, these bars provide robustness for reinforcements in beams and columns. Engineers appreciate their lightweight nature, which eases installation and reduces structural load.

In the automotive sector, pultruded carbon fiber bars enhance vehicle strength while minimizing weight. They are used in chassis and body frames, contributing to increased fuel efficiency. Aerospace applications benefit from similar properties, where the material's durability can improve aircraft performance.

Tip: When selecting pultruded carbon fiber bars, consider the environment and stress factors. Ensure compatibility with the project’s specific needs.

Another interesting application is in sports equipment. High-performance bikes and fishing rods utilize these bars for superior flexibility and strength. However, manufacturers must address the limitations of carbon fibers, such as sensitivity to impact.

Tip: Always test your materials before final production for best results. Adaptation may be necessary to meet precise requirements.

This chart illustrates the various applications of pultruded carbon fiber bars in different industries. The data represents the estimated percentage of usage across these sectors, highlighting the significant roles carbon fiber plays in enhancing performance and durability.

When comparing pultruded carbon fiber bars with other materials like steel and aluminum, several factors come into play. Pultruded carbon fiber is lighter than both metals. This weight reduction can lead to easier handling and transportation. On the other hand, steel offers great strength but adds significant weight. Aluminum serves as a middle ground in terms of weight and strength, yet it doesn't match carbon fiber's stiffness.

The corrosion resistance of pultruded carbon fiber is another key benefit. Unlike metals that may rust or corrode, carbon fiber bars retain their integrity over time. This durability is crucial in demanding environments. However, the production process for carbon fiber can be more complex and costly than for metals. Some may find it challenging to justify the price, especially for smaller projects.

Ultimately, each material has its own benefits and limitations. Carbon fiber can be a perfect choice for lightweight and high-performance applications. However, users must consider factors like cost and the specific needs of their projects. The decision isn't always straightforward. Proper evaluation of intended use is essential.