-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

When it comes to selecting the right materials for your projects, the choice of the forged carbon sheet can have a significant impact on both functionality and aesthetic appeal. As the industry continues to evolve, experts are emphasizing the importance of informed decision-making. One such expert, Dr. Emily Chen, a leading authority in material science, states, "Choosing the right forged carbon sheet is not merely about specifications; it’s about understanding the unique properties that each sheet brings to your project." This insight underscores the necessity for engineers and designers to delve deeper into the characteristics of forged carbon sheets to optimize their applications.

Forged carbon sheets are renowned for their impressive strength-to-weight ratio and customizability, making them a preferred choice in industries ranging from automotive to aerospace. However, with various grades and finishes available, the selection process can be daunting. The desire for innovation and performance in projects necessitates a comprehensive understanding of these materials. As you prepare to embark on your next venture, consider the critical factors that will determine the effectiveness of your chosen forged carbon sheet. Each decision can influence the outcome, ensuring that your project not only meets but exceeds expectations.

Forged carbon is rapidly gaining popularity in various industries due to its unique properties and benefits. This composite material, created by compressing carbon fibers under heat and pressure, offers remarkable strength and lightweight characteristics. Its inherent durability makes it an ideal choice for projects where high performance and resilience are critical, such as in automotive, aerospace, and sporting goods applications. Additionally, forged carbon is resistant to corrosion and extreme temperatures, further enhancing its adaptability in diverse environments.

When selecting the right forged carbon sheet for your project, consider the specific requirements of your application. Ensure that the thickness and size of the sheet align with your design specifications, as these factors influence both the performance and aesthetic appeal of the final product. Another tip is to assess the finish of the material; forged carbon sheets are available in various textures, which can impact the visual appeal and tactile experience of your project.

Finally, evaluate the potential for customization. Many manufacturers offer bespoke options that can meet unique project demands. This flexibility allows you to tailor the forged carbon sheets to match specific performance characteristics or design elements, giving your project a competitive edge. By understanding the properties and benefits of forged carbon, you can make informed decisions that elevate the quality and functionality of your work.

This chart illustrates key properties of forged carbon sheets that may influence your project decisions, including weight, tensile strength, thermal conductivity, impact resistance, and cost.

When selecting forged carbon sheets for your projects, several key factors play a crucial role in ensuring you make the best choice for your specific needs. First and foremost, it is essential to consider the mechanical properties of the material. Forged carbon is known for its exceptional strength-to-weight ratio, often exceeding that of traditional materials. According to industry reports, the tensile strength of forged carbon can reach up to 1000 MPa, providing significant advantages in applications requiring high durability and performance, such as aerospace and automotive industries.

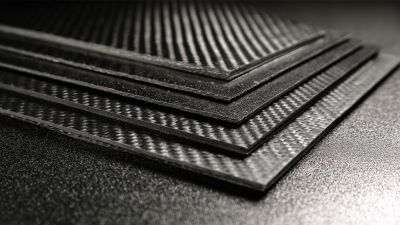

Another critical factor to consider is the thickness and size of the forged carbon sheet. The dimensions should align not only with the project's requirements but also with the available manufacturing capabilities. Many suppliers report that sheets typically range from 0.5 mm to 10 mm in thickness, impacting the rigidity and overall structural integrity of the final product. Additionally, examining the fiber orientation during the selection process can have notable effects on performance characteristics; an optimal orientation can enhance load distribution and impact resistance. By thoroughly evaluating these factors, you can select the right forged carbon sheet that meets the demands of your project efficiently and effectively.

When it comes to selecting forged carbon sheets for specific applications, understanding the differences between standard and custom options is crucial. Standard forged carbon sheets are designed to meet general specifications and are readily available in various thicknesses and finishes. According to industry reports, these sheets have gained popularity in sectors such as automotive and aerospace due to their excellent strength-to-weight ratio and durability. Typically, standard sheets are suitable for projects that require consistent performance under uniform conditions, addressing common needs without significant modifications.

On the other hand, custom forged carbon sheets offer a tailored solution for specialized applications that demand unique properties or dimensions. This customization can include variations in fiber orientation, resin types, and thickness, allowing engineers to optimize material performance for specific load-bearing requirements or environmental challenges. A recent study indicated that projects employing custom sheets can achieve performance improvements of up to 30% compared to those using standard products, particularly in high-stress environments. As industries increasingly prioritize efficiency and innovation, understanding these differences enables project managers and engineers to make informed choices that enhance product performance and reliability.

| Feature | Standard Forged Carbon Sheets | Custom Forged Carbon Sheets |

|---|---|---|

| Cost | Lower | Higher |

| Lead Time | Shorter | Longer |

| Customization Level | Limited options | Highly customizable |

| Performance | Standard properties | Tailored to specific needs |

| Availability | Readily available | Made to order |

Forged carbon sheets have gained significant traction across various industries due to their unique properties and versatility. The automotive sector, for instance, stands out as a primary application area. According to a recent report by the Global Carbon Fiber Market Research, the automotive industry is projected to account for over 30% of carbon fiber applications by 2025, highlighting the data-driven shift towards lightweight materials. Forged carbon’s superior strength-to-weight ratio allows manufacturers to enhance fuel efficiency and performance while meeting stringent safety regulations.

In aerospace, the utilization of forged carbon sheets is growing rapidly, driven by the demand for advanced composite materials. A study published by the Aerospace Materials Research Society indicates that composites are expected to represent 50% of the volume of some aircraft structures over the next decade. The exceptional rigidity and damage tolerance of forged carbon make it an ideal choice for aircraft components, contributing to reduced weight and improved fuel efficiency. Moreover, the ability to mold complex shapes efficiently allows engineers to innovate in designing airframes, ultimately leading to enhanced operational performance in the competitive aerospace market.

The sporting goods sector also benefits from forged carbon sheets, particularly in high-performance equipment such as bicycles and golf clubs. Research from the Sports Equipment Manufacturing Association shows that the demand for lightweight and durable materials has doubled over the last five years, with composites leading the charge. The unique aesthetics and performance attributes of forged carbon provide manufacturers a competitive edge, catering to consumers increasingly focused on both efficiency and style.

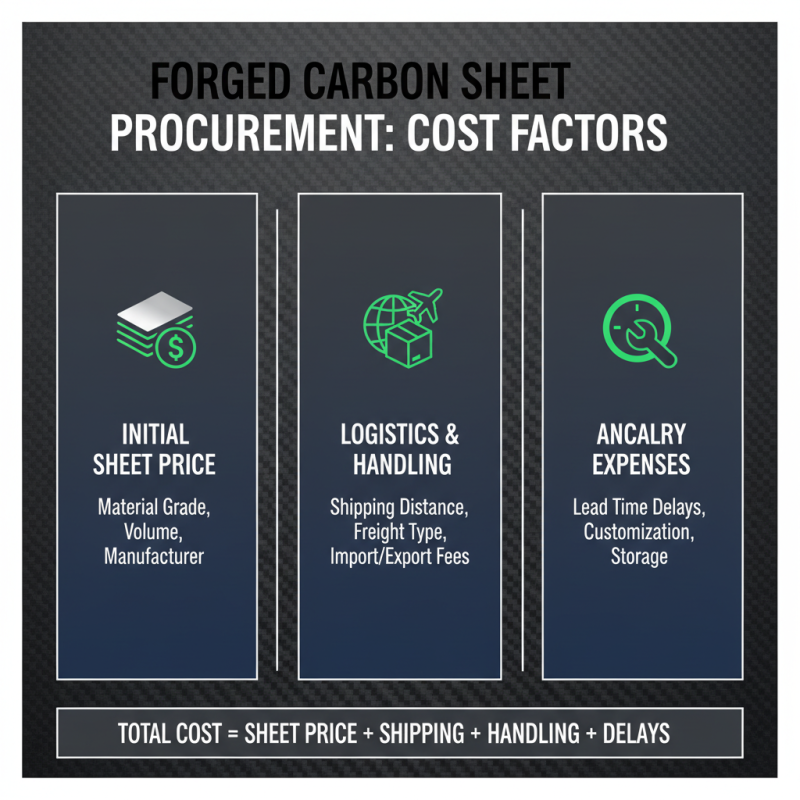

When budgeting for forged carbon sheet procurement, it's crucial to understand the various factors that influence overall costs. The initial price per sheet is only part of the equation; you must also consider shipping, handling, and any additional ancillary expenses that may arise during the procurement process. For example, sourcing from a local supplier might reduce shipping costs, while a longer lead time from an overseas supplier could prove costly in terms of delayed project timelines.

Additionally, consider the potential long-term savings associated with investing in higher-quality materials. While cheaper options might seem appealing initially, they can lead to increased maintenance costs or reduced performance in the final application. Assessing the total cost of ownership, which includes the price of the material, the lifespan, and the performance reliability, will help ensure that the chosen forged carbon sheet not only fits the current budget but also contributes to the project’s overall success. Prioritizing quality alongside cost can lead to more sustainable choices that benefit both the project and the bottom line.