-

Home

-

Products

-

About Us

-

News

-

Blog

-

Video

-

Contact

Leave Your Message

In the evolving landscape of advanced materials, Pultruded Carbon Fiber Bars have emerged as a pivotal solution in various engineering and architectural applications. According to a recent market analysis by Research and Markets, the global carbon fiber market is projected to reach $46.75 billion by 2027, driven by the increasing demand for lightweight and high-strength materials in industries such as aerospace, automotive, and construction. The unique properties of Pultruded Carbon Fiber Bars—such as their exceptional strength-to-weight ratio and resistance to corrosion—make them an ideal choice for a wide range of projects.

Expert Dr. Emily Thompson, a renowned specialist in composite materials, emphasizes the importance of careful selection when it comes to these bars: "Choosing the right Pultruded Carbon Fiber Bar can significantly impact the performance and longevity of your project. It's essential to consider factors such as material specification, environmental conditions, and load requirements." With the market expanding and more options becoming available, understanding the critical elements involved in selecting the best Pultruded Carbon Fiber Bar is crucial for engineers and designers alike. This article will explore ten essential tips to guide professionals in making informed decisions that will lead to successful project outcomes.

Pultruded carbon fiber bars are integral components in various engineering projects, known for their lightweight yet high-strength properties. These bars are manufactured through a continuous process that combines resin with aligned fibers, resulting in a material that exhibits superior mechanical performance. According to the “Composite Materials Market Report” by MarketsandMarkets, the carbon fiber composites market is projected to reach $34.9 billion by 2025, highlighting the increasing demand for materials that enhance structural efficiency in industries such as aerospace, automotive, and construction.

In applications where weight savings and strength are critical, pultruded carbon fiber bars offer significant advantages. For instance, in the aerospace sector, reducing weight can lead to increased fuel efficiency, making carbon fiber a go-to choice for aircraft manufacturers. The American Composites Manufacturers Association (ACMA) emphasizes that composite materials can be up to 70% lighter than their metal counterparts while maintaining superior tensile strength, making them ideal for high-performance applications. As industries continue to prioritize sustainable and innovative solutions, understanding the benefits and applications of pultruded carbon fiber bars becomes essential in staying competitive in the market.

When selecting the best pultruded carbon fiber bar for your projects, it's essential to understand the key factors that influence their performance and suitability for specific applications. One of the primary considerations is the tensile strength of the carbon fiber material. Reports from the Composite Materials Handbook indicate that high-performance carbon fiber can reach tensile strengths of up to 600 ksi (kilopounds per square inch), significantly improving the durability and load-bearing capacity of structures compared to traditional materials like aluminum and steel.

Another critical aspect to consider is the fiber alignment within the composite. Proper alignment enhances the overall mechanical properties of the bar. According to a study published in the Journal of Composite Materials, pultruded carbon fiber bars exhibiting unidirectional fiber alignment showed a 30% increase in stiffness and strength compared to those with random fiber distribution. Moreover, assessing the resin system used in the pultrusion process can impact both performance and resistance to environmental conditions; for example, epoxy resins typically offer superior chemical resistance and thermal stability, making them ideal for applications in demanding environments. Understanding these factors will guide you toward making informed decisions in choosing the right pultruded carbon fiber bar for your specific needs.

When evaluating pultruded carbon fiber bars for your projects, strength and weight specifications are paramount. Carbon fiber is renowned for its high strength-to-weight ratio, making it an excellent choice for applications requiring robust materials that are also lightweight. When selecting a carbon fiber bar, first focus on tensile strength, which indicates how much force can be applied before the material fails. This is crucial for ensuring that the bar can withstand the stresses it will encounter during use. Look for material specifications that provide clarity on the tensile strength rating, as this will help you gauge whether a particular product is suitable for your specific needs.

In addition to strength, weight is another critical factor to consider. The lightweight nature of pultruded carbon fiber can significantly impact the overall design and functionality of your project. Understanding the specific weight of the bar versus its strength will help you make informed decisions, particularly for applications where weight reduction is essential, such as in aerospace or automotive industries. Pay attention to the bar's density and ensure it aligns with your project requirements. Balancing these two specifications—strength and weight—will enable you to select the best carbon fiber bar that meets both performance and design criteria.

When considering the cost of pultruded carbon fiber bars, it's essential to evaluate both the initial investment and the long-term value they bring to your projects. While the upfront cost of carbon fiber can be significantly higher than traditional materials such as aluminum or steel, the durability and lightweight properties often lead to reduced costs in maintenance and transportation. Assessing the total cost of ownership can reveal that these bars are a more economical choice over time, especially for applications requiring high strength-to-weight ratios.

Budget considerations also play a critical role in the selection process. It’s advisable to compare prices from different suppliers and consider the specific requirements of your project. Factors such as tensile strength, dimensions, and environmental resistance can impact pricing. Additionally, exploring bulk purchasing options can lead to significant savings. Keeping your project’s specific needs in mind will help ensure that you invest wisely in pultruded carbon fiber bars that provide the best balance between cost and performance.

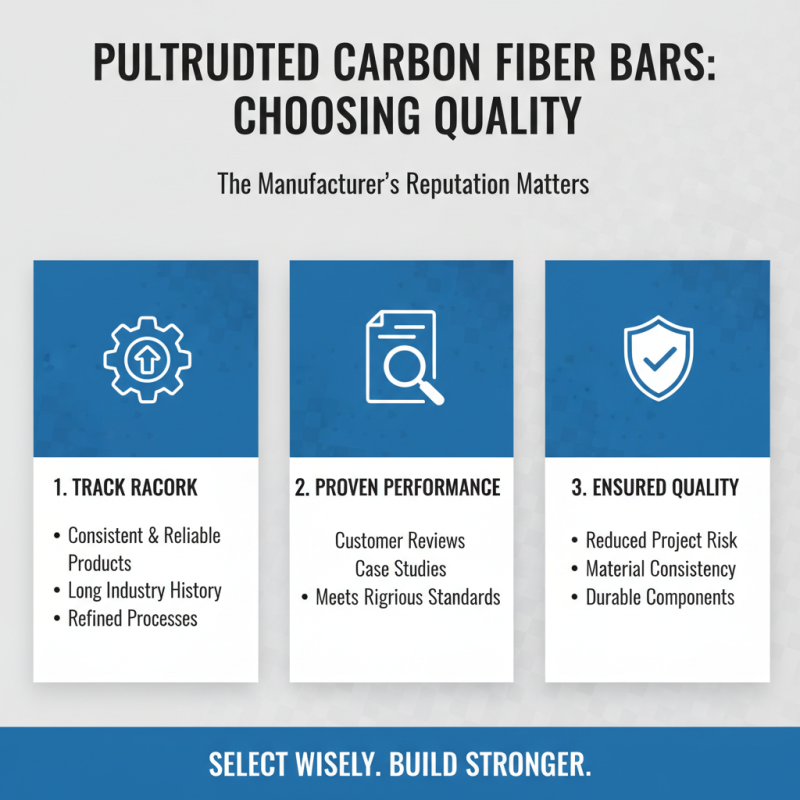

When selecting pultruded carbon fiber bars for your projects, the reputation of the manufacturer plays a crucial role in ensuring the quality of the materials you choose. A manufacturer with a solid track record is likely to produce consistent and reliable products. Investigate their history in the industry, paying attention to customer reviews and case studies that speak to their performance over time. Established manufacturers often have a refined process, ensuring that their carbon fiber bars meet rigorous standards.

Additionally, certifications can provide significant assurance regarding the quality of the products. Look for manufacturers that possess relevant industry certifications, such as ISO quality management, which indicate adherence to high production and safety standards. Certifications are not only a mark of trust but also reflect a manufacturer’s commitment to innovation and environmental responsibility. By prioritizing manufacturers with robust reputations and recognized certifications, you can confidently select a pultruded carbon fiber bar that meets your project requirements and ensures optimal performance.